5.3 Stopping 5 Installation and first start

46

5.4.3 Separation

• Supply process liquid.

• Check the inlet pressure, see “Selection of

outlet impeller (twin phase separators)” in

Installation Manual

.

• Adjust the outlet pressures, see “Selection of

outlet impeller (twin phase separators)” in

Installation Manual

.

5.4.4 Operation

• Check the throughput. Make a final

adjustment of inlet and outlet pressures.

• Make sure that no air is being sucked into the

feed pipe via e.g.a balance vessel, if fitted.

This should always be kept filled. The

process liquid should flow evenly in the

vessel without bubbling.

After separation is completed, carry out the

cleaning programme. Dismantle the bowl and

check the cleaning 3 – 4 days after the first

operation with product.

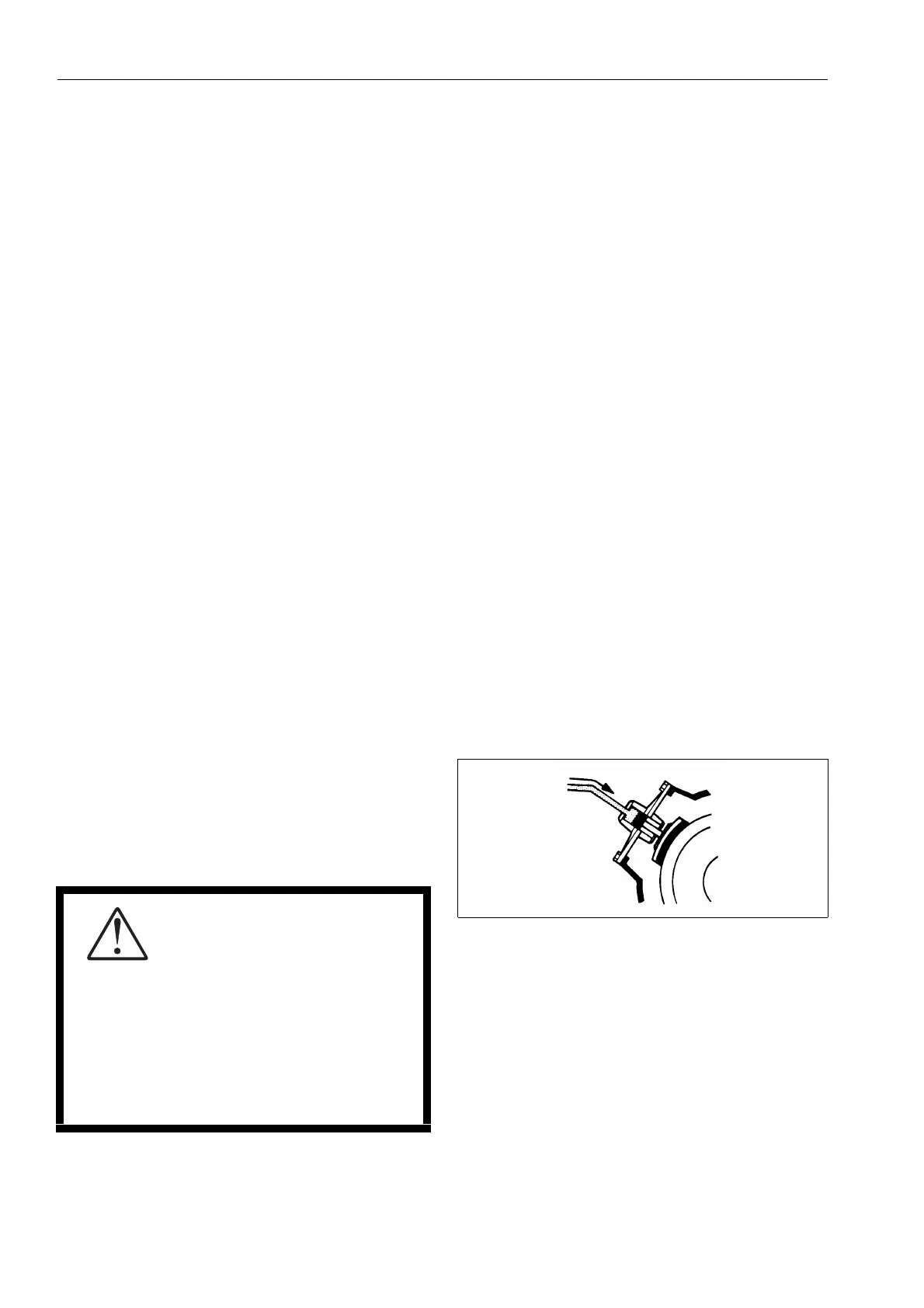

5.5 Stopping

The control system actuates the brake when

stopping the separator.

Cooling water to the axial seals and air to the

brake will be turned off automatically after the

bowl has stopped.

DANGER

Entrapment hazard

Make sure that rotating parts have come to

a complete standstill before starting any

dismantling work.

The revolution counter indicates separator

rotation.

S0118411

Loading...

Loading...