59

8 Trouble tracing 8.2 Sediment discharge function

8.2 Sediment discharge

function

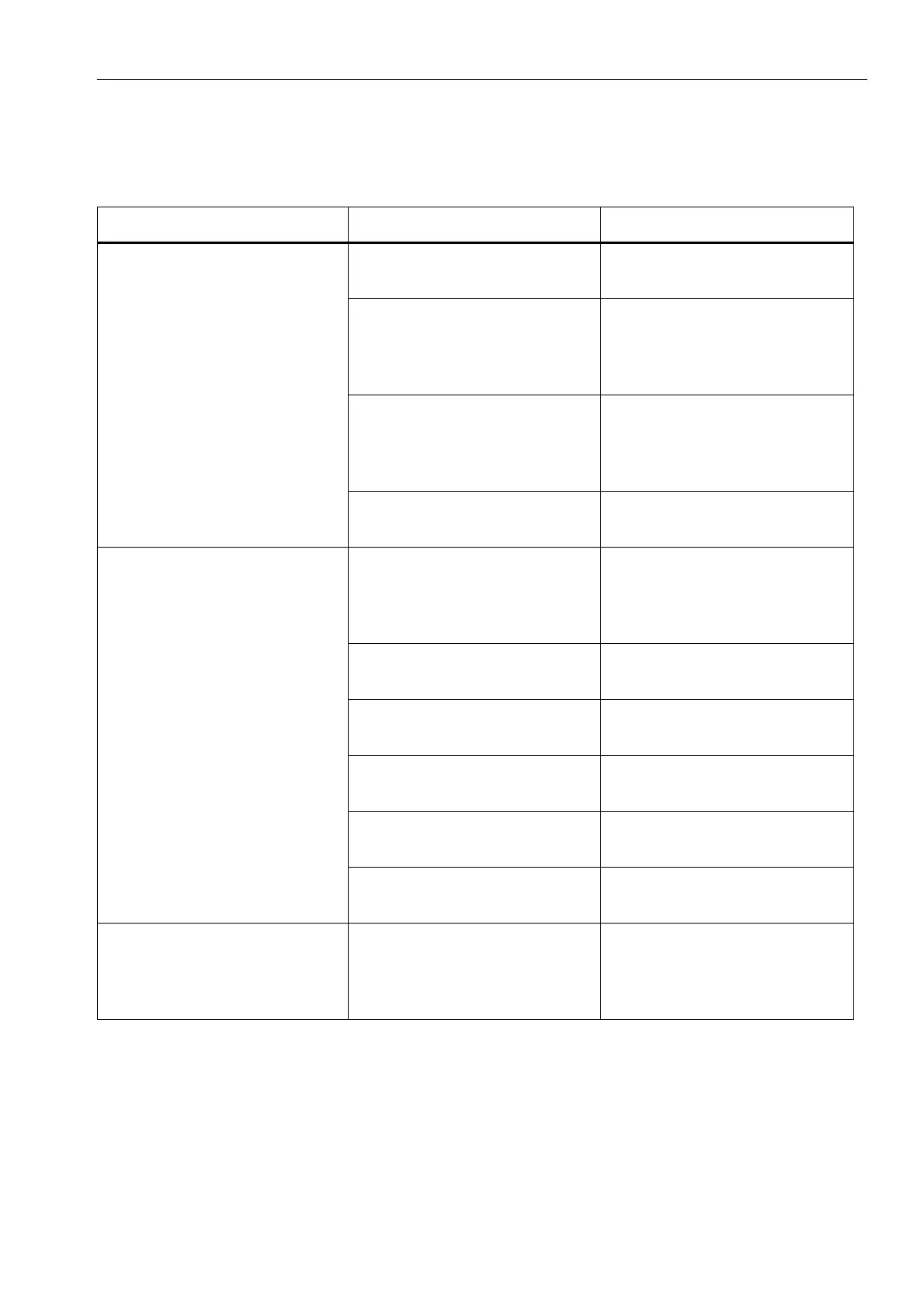

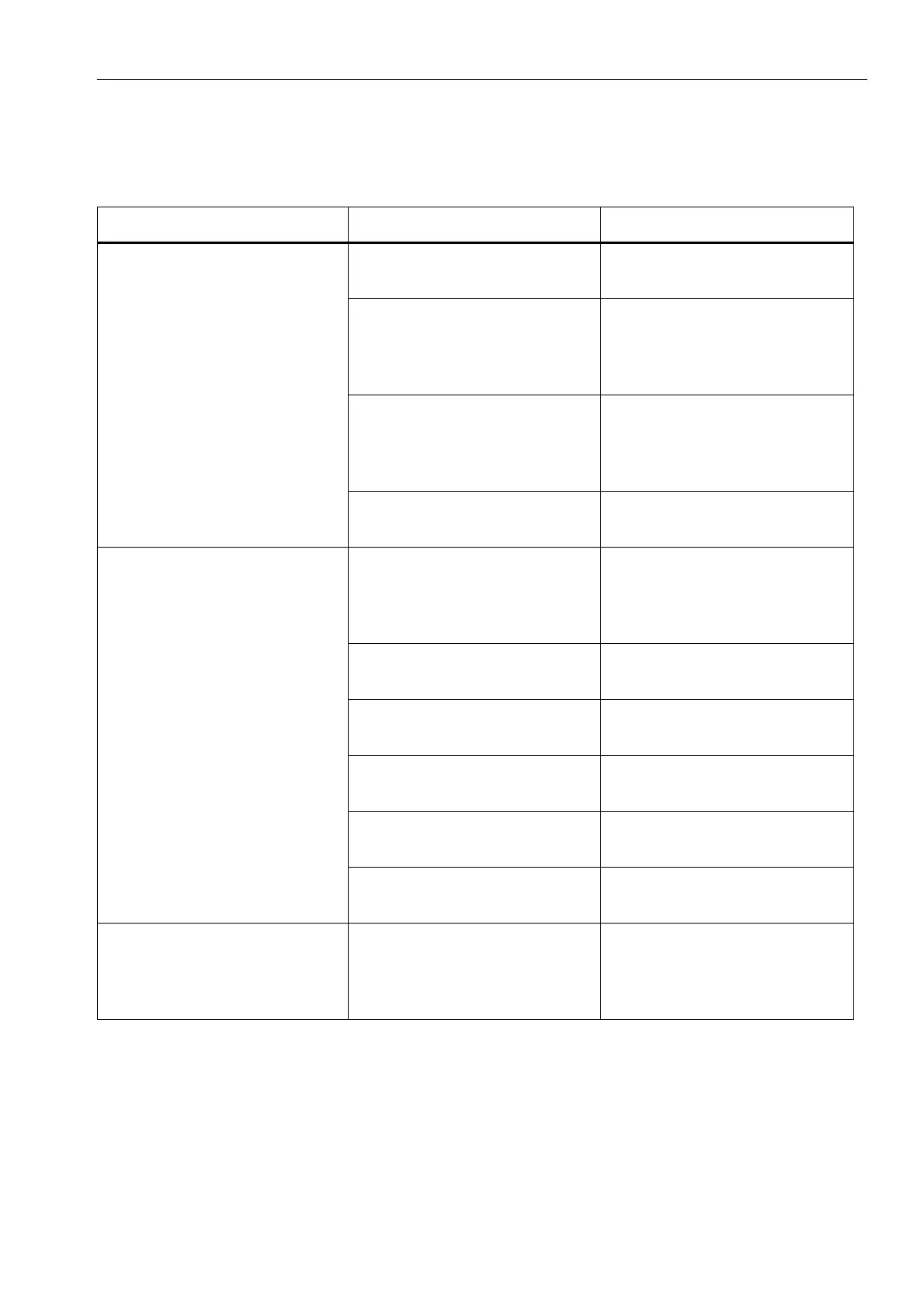

Indication Cause Remedy

The bowl does not eject or

the volume is too small

Air bubbles in piping between

the OWMC and the separator

Purge the system for air

Operating water leakage

through valve plugs in

operating slide or seal ring in

sliding bowl bottom

Change the seals

When intervals between

discharges are long (≥ 1 h) the

operating mechanism may

seize

Discharge twice in order to

reset the system to normal

volume

Incorrect operating pressure

and time adjustment

Correct

The bowl does not close No water in the operating

water tank or the pressure

from the reducing valve is

insufficient

Check the water supply. Adjust

the pressure to maximum

value (approx. 70 kPa) but

avoid leakage (max 50 l/h)

The valve plugs in operating

slide leak

Change the valve plugs

The seal ring in the sliding

bowl bottom leaks

Change the seal ring

Impurities under the sliding

bowl bottom

Clean

Seizure on the bowl nave Remedy according to

instructions for maintenance

The seal ring for bowl hood

leaks

Change the seal ring

The discharge volume

increases

This may occur if leakage of

operating water increases due

to readjustment of operating

water pressure

Run the separator with

constant operating water

pressure

Loading...

Loading...