8.2 Sediment discharge function 8 Trouble tracing

60

8.2.1 OWMC related faults

1) See

Installation Manual

2) See

“Operating water module (OWMC)”

in

Service & Maintenance Manual

3)

See Installation Manual, “Connection

list”

, connection 375

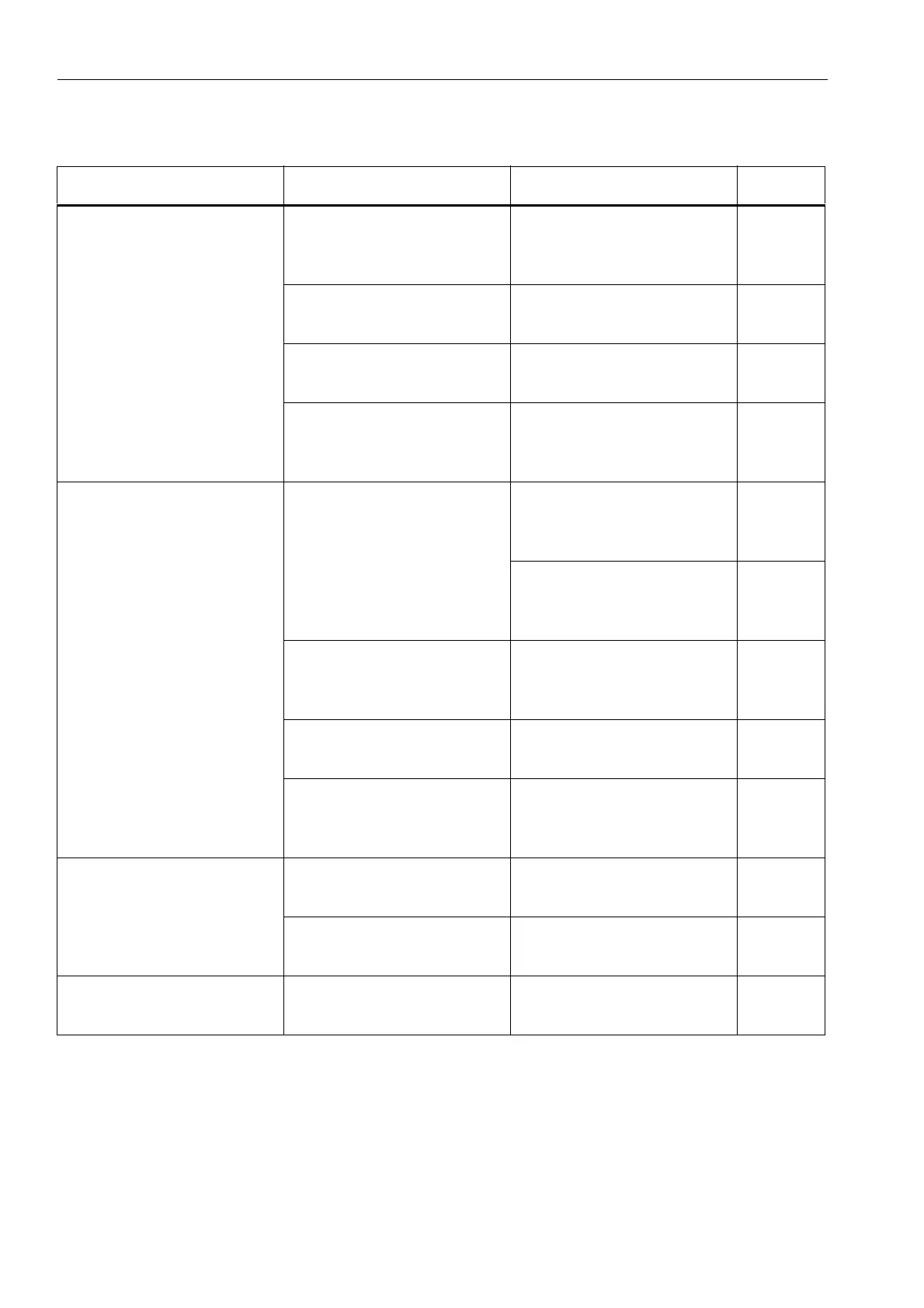

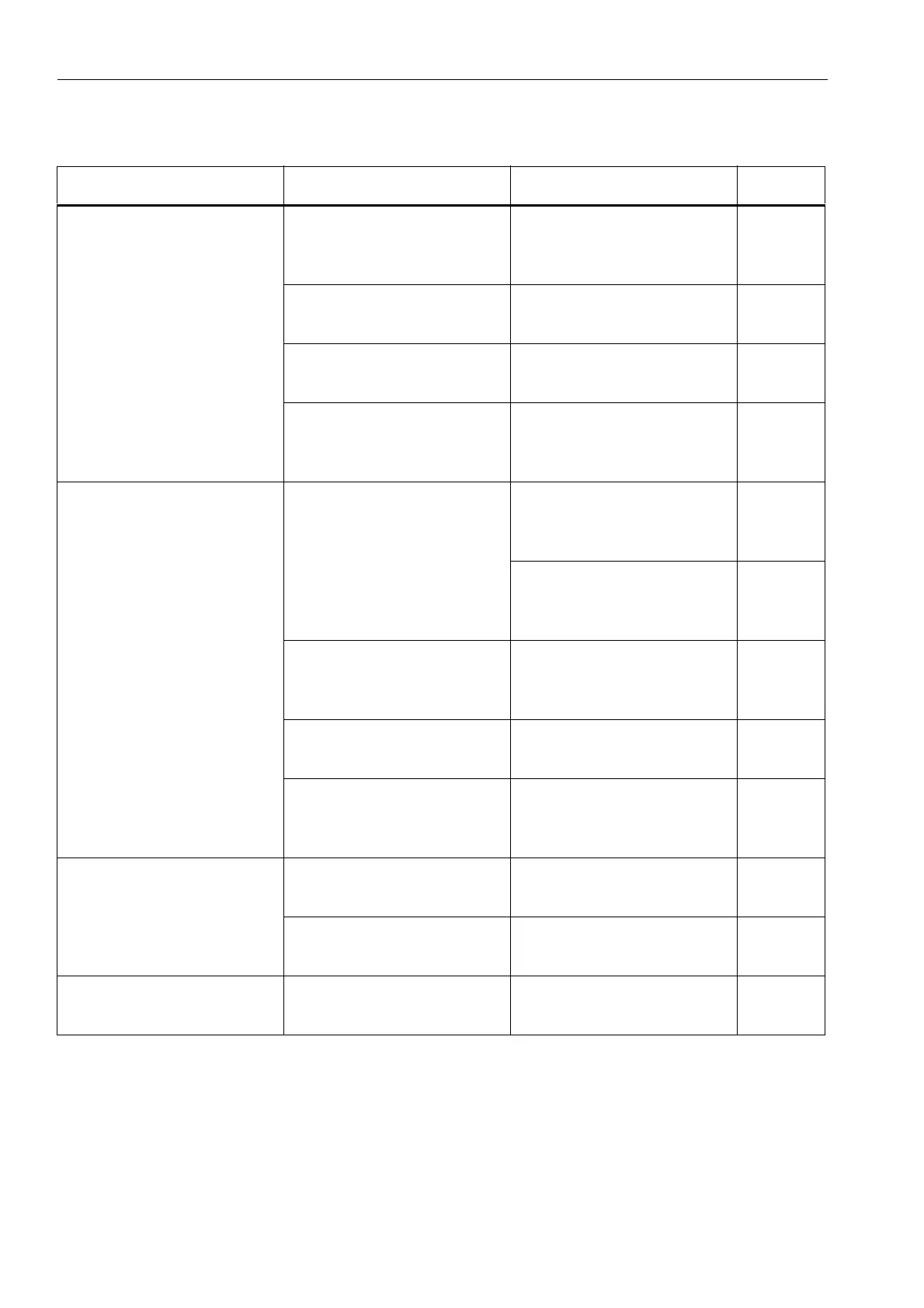

Indication Cause Corrective actions Page

The bowl does not eject

or the volume is too

small

Needle valve for setting of

small discharge is throttled

too much

Adjust the throttling 40

Air pressure for setting of

large discharge is too low

Adjust the air pressure 40

No supply or signal air to

the OWMC

Check the air supply –

Faulty check valve in

operating water feed line

before the OWMC inlet

Check function of the valve –

OWMC piston does not

return to its initial

position or returns too

slowly

Impurities in water or air

which increase friction

between piston and

cylinder

Follow the instructions

carefully for air and water

quality.

1)

Clean and lubricate piston

and cylinder with

GLEITMO 1821V

2)

Too low operating water

pressure in the feed line

before the OWMC

Check the operating water

pressure

3)

Silencer for air outlet in the

OWMC is clogged

Renew the silencer –

Faulty check valve in

operating water feed line

before the OWMC inlet

Check function of the valve –

The discharged volume

too large

Faulty sealing for the two-

pulse adapter

Renew the sealing 2)

pos. 8

Too high pressure of the air

supply (506a).

Reduce the air pressure 40

Bowl fails to close after

sediment discharge

Clogged nozzle fitted in the

two-pulse adapter

Clean the nozzle 2)

Loading...

Loading...