8.3 Axial seals 8 Trouble tracing

62

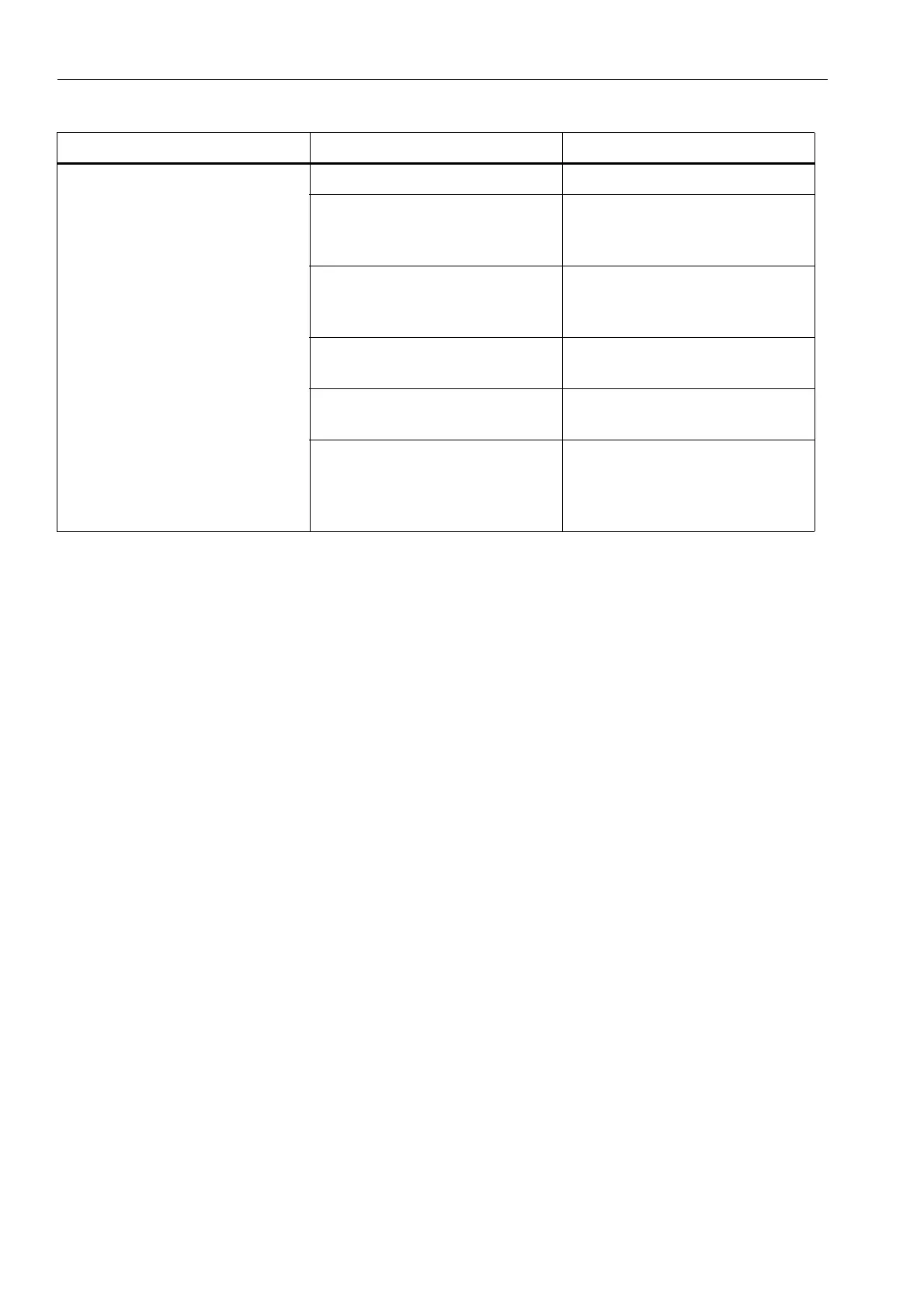

Indication Cause Remedy

Leaky seals Normal wear –

Separator has been run without

contact between seals and

liquid

Seals must never run dry.

Always check that liquid is fed

to the seals

Deposits have formed on seals

because of insufficient cleaning

programme

Adjust the cleaning programme

Bowl is out of balance* See ‘‘ Machine vibrates

(vibration alarm)” on page 57

Frame hood is not centered in

relation to the outlet pipe*

Adjust the centering ring

High product outlet pressures

(e.g. because a discharge

conduit has been closed

unintentionally

The axial seals must not be

subjected to pressures above

600 kPa (6 bar).

* Does not refer to the inlet seal

Loading...

Loading...