Rockwell Automation Publication 520-UM001A-EN-E - February 2013 33

Installation/Wiring Chapter 1

(2) Two wire control shown. For three wire control use a momentary input on I/O Terminal 02 to command a start. Use a

maintained input for I/O Terminal 03 to change direction.

(3) When using an opto output with an inductive load such as a relay, install a recovery diode parallel to the relay as shown, to prevent

damage to the output.

t064 [2-Wire Mode] Normal Stop I/O Terminal 01 Stop

0 “Edge Trigger” Per P045

[Stop Mode]

Coast

1 “Level Sense” Per P045 [Stop Mode]

2 “Hi-Spd Edge” Coast

3 “Momentary” Per P045 [Stop Mode]

The drive is shipped with a jumper installed between I/O Terminals 01 and 11.

Remove this jumper when using I/O Terminal 01 as a stop or enable input.

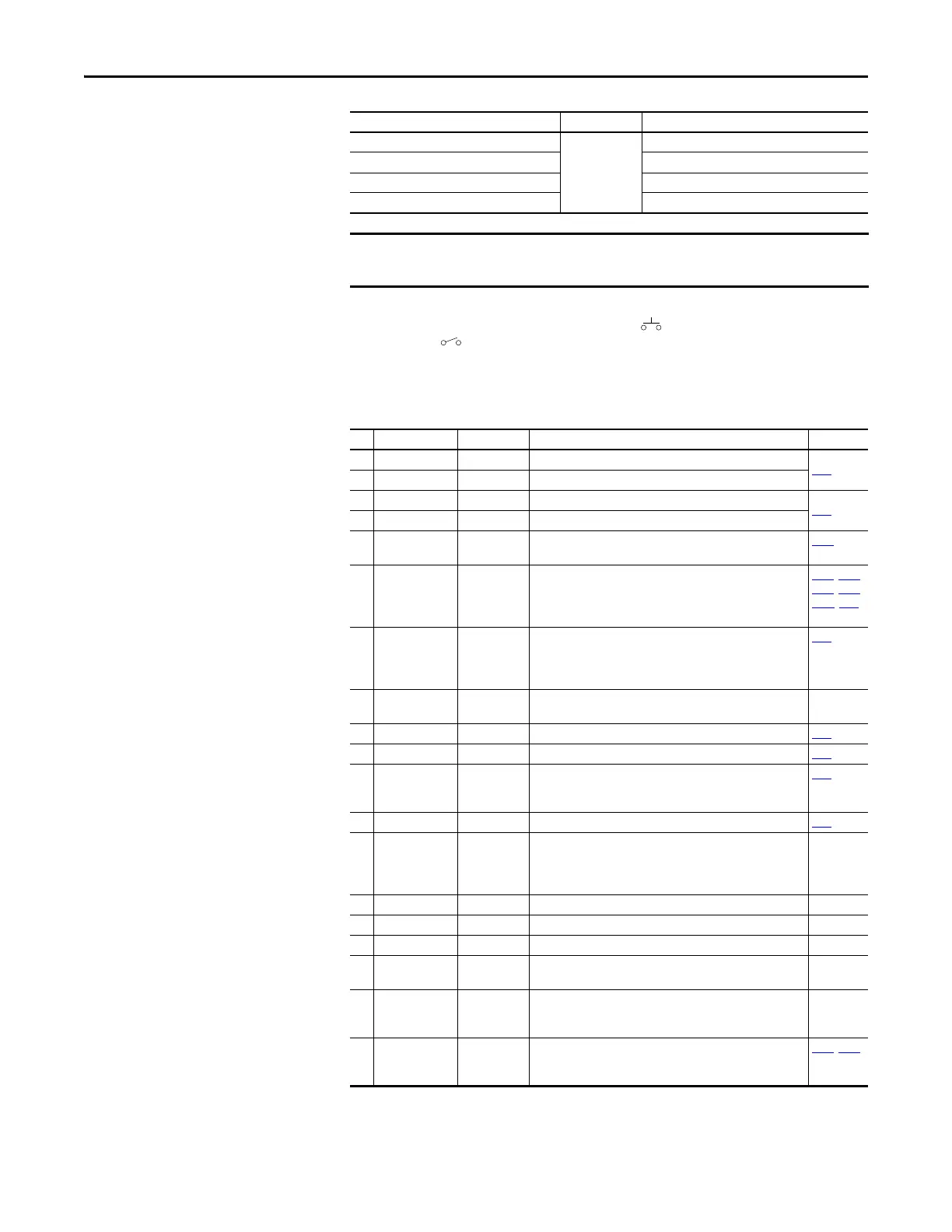

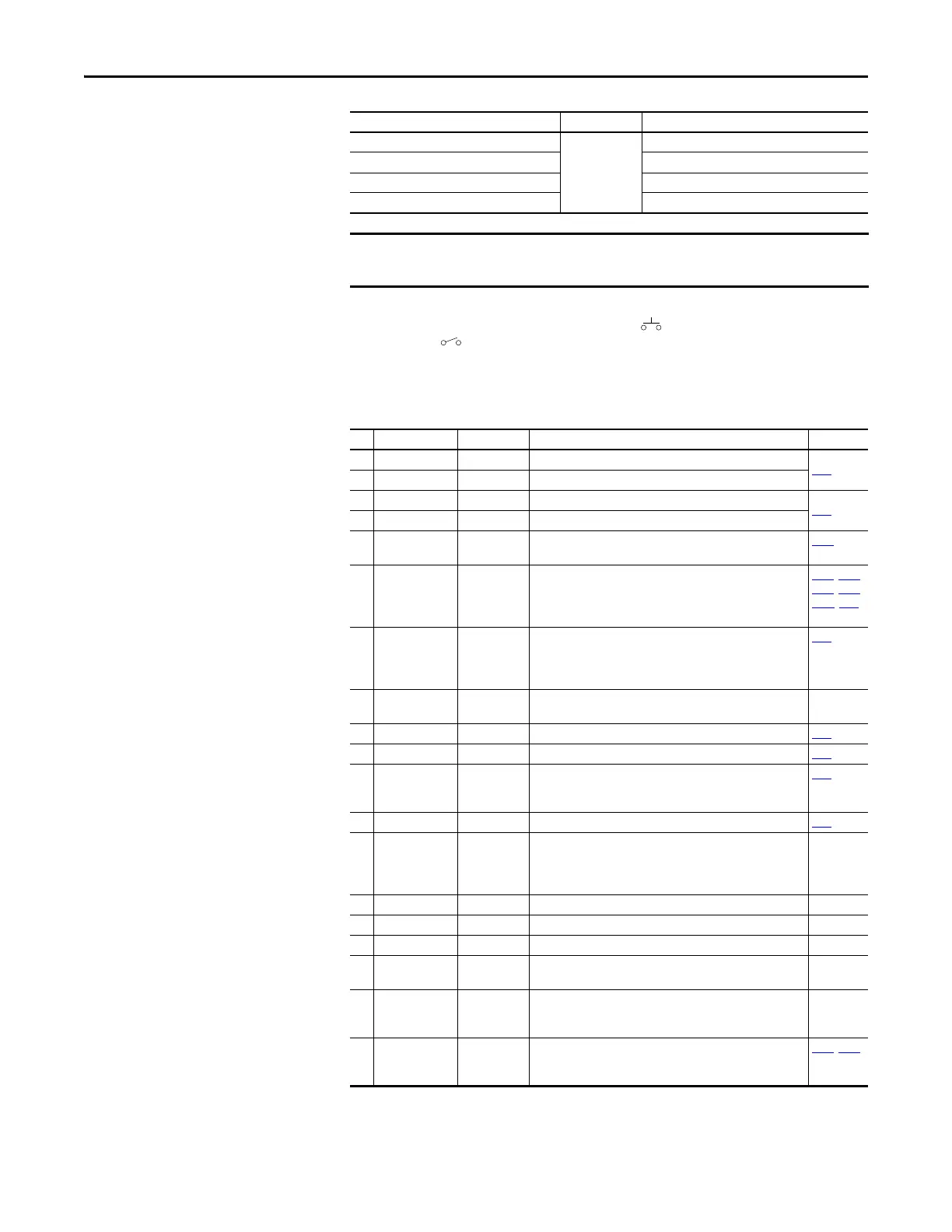

Control I/O Terminal Designations

No. Signal Default Description Parameter

R1 Relay 1 N.O. Fault Normally open contact for output relay.

t076

R2 Relay 1 Common Fault Common for output relay.

R5 Relay 2 Common Motor Running Common for output relay.

t081

R6 Relay 2 N.C. Motor Running Normally closed contact for output relay.

01 Stop Coast Three wire stop. However, it functions as a stop under all input

modes and cannot be disabled.

P045

(1)

02 DigIn TermBlk 02/

Start/Run FWD

Run FWD Used to initiate motion and also can be used as a programmable

digital input. It can be programmed with t062 [DigIn TermBlk

02] as three wire (Start/Dir with Stop) or two wire (Run FWD/

Run REV) control.

P045, P046,

P048, P050,

A544, t062

03 DigIn TermBlk 03/

Dir/Run REV

Run REV Used to initiate motion and also can be used as a programmable

digital input. It can be programmed with t063 [DigIn TermBlk

03] as three wire (Start/Dir with Stop) or two wire (Run FWD/

Run REV) control.

t063

04 Digital Common – Return for digital I/O. Electrically isolated (along with the digital

I/O) from the rest of the drive.

–

05 DigIn TermBlk 05 Preset Freq Program with t065 [DigIn TermBlk 05]. t065

06 DigIn TermBlk 06 Preset Freq Program with t066 [DigIn TermBlk 06]. t066

07 DigIn TermBlk 07/

Pulse In

Start Source 2

+ Speed

Reference2

Program with t067 [DigIn TermBlk 07]. Also functions as a Pulse

Train input for reference or speed feedback. The maximum

frequency is 100 kHz.

t067

08 DigIn TermBlk 08 Jog Forward Program with t068 [DigIn TermBlk 08]. t068

C1 C1 – This terminal is tied directly to the RJ-45 and USB shields on the

Keypad printed circuit board (PCB). Ties this shield to earth

ground in order to improve noise immunity when using external

communication peripherals.

–

C2 C2 – This is the signal common for the communication signals. –

S1 Safety 1 – Safety input 1. Current consumption is 6 mA. –

S2 Safety 2 – Safety input 2. Current consumption is 6 mA. –

S+ Safety +24V – +24V supply for safety circuit. Internally tied to the +24V DC

source (Pin 11).

–

11 +24V DC – Referenced to Digital Common.

Drive supplied power for digital inputs.

Maximum output current is 100 mA.

–

12 +10V DC – Referenced to Analog Common.

Drive supplied power for 0...10V external potentiometer.

Maximum output current is 15 mA.

P047

, P049

Loading...

Loading...