36 Rockwell Automation Publication 20A-UM001N-EN-P - July 2013

Chapter 1 Programming and Parameters

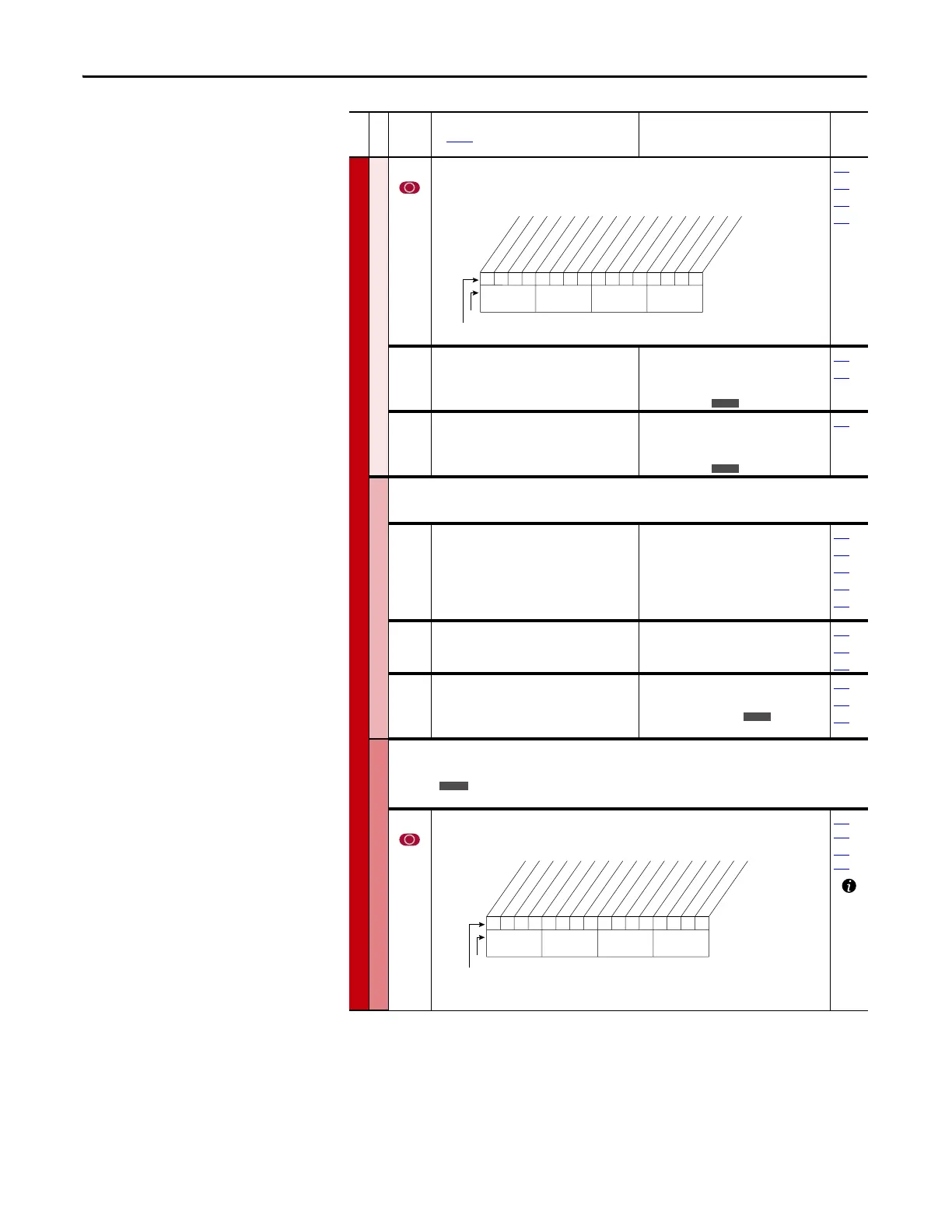

SPEED COMMAND (file C)

Speed Trim

118 [Trim Out Select]

Specifies the speed references to be trimmed. To apply negative trim, P190 [Direction Mode]

must be set to 1 “Bipolar.”

117

119

120

190

119 [Trim Hi]

Scales the upper value of the [Trim In Select]

selection when the source is an analog input.

Default:

Min/Max:

Units:

60.0 Hz

±[Maximum Speed]

0.1 Hz

1 %

082

117

120 [Trim Lo]

Scales the lower value of the [Trim In Select]

selection when the source is an analog input.

Default:

Min/Max:

Units:

0.0 Hz

±[Maximum Speed]

0.1 Hz

1 %

117

Slip Comp

Important: Parameters in the Slip Comp Group are used to enable and tune the Slip

Compensation Regulator. For the Slip Compensation Regulator to control drive operation, set

parameter 080 to 1 “Slip Comp”.

121 [Slip RPM @ FLA]

Sets the amount of compensation to drive

output at motor FLA.

If the value of parameter 061 [Autotune] = 3

“Calculate” changes made to this parameter are

not accepted.

Default:

Min/Max:

Units:

Based on [Motor NP RPM]

0.0/1200.0 rpm

0.1 rpm

044

061

080

122

123

122 [Slip Comp Gain]

Sets the response time of slip compensation.

Default:

Min/Max:

Units:

40.0

1.0/100.0

0.1

080

121

122

123 [Slip RPM Meter]

Displays the present amount of adjustment

being applied as slip compensation.

Default:

Min/Max:

Units:

Read Only

0.0/300.0 rpm

±300.0 rpm

0.1 rpm

080

121

122

Process PI

Important: Parameters in the Process PI Group are used to enable and tune the PI Loop.

For the PI Loop to control drive operation, set parameter 080 to 2 “Process PI”.

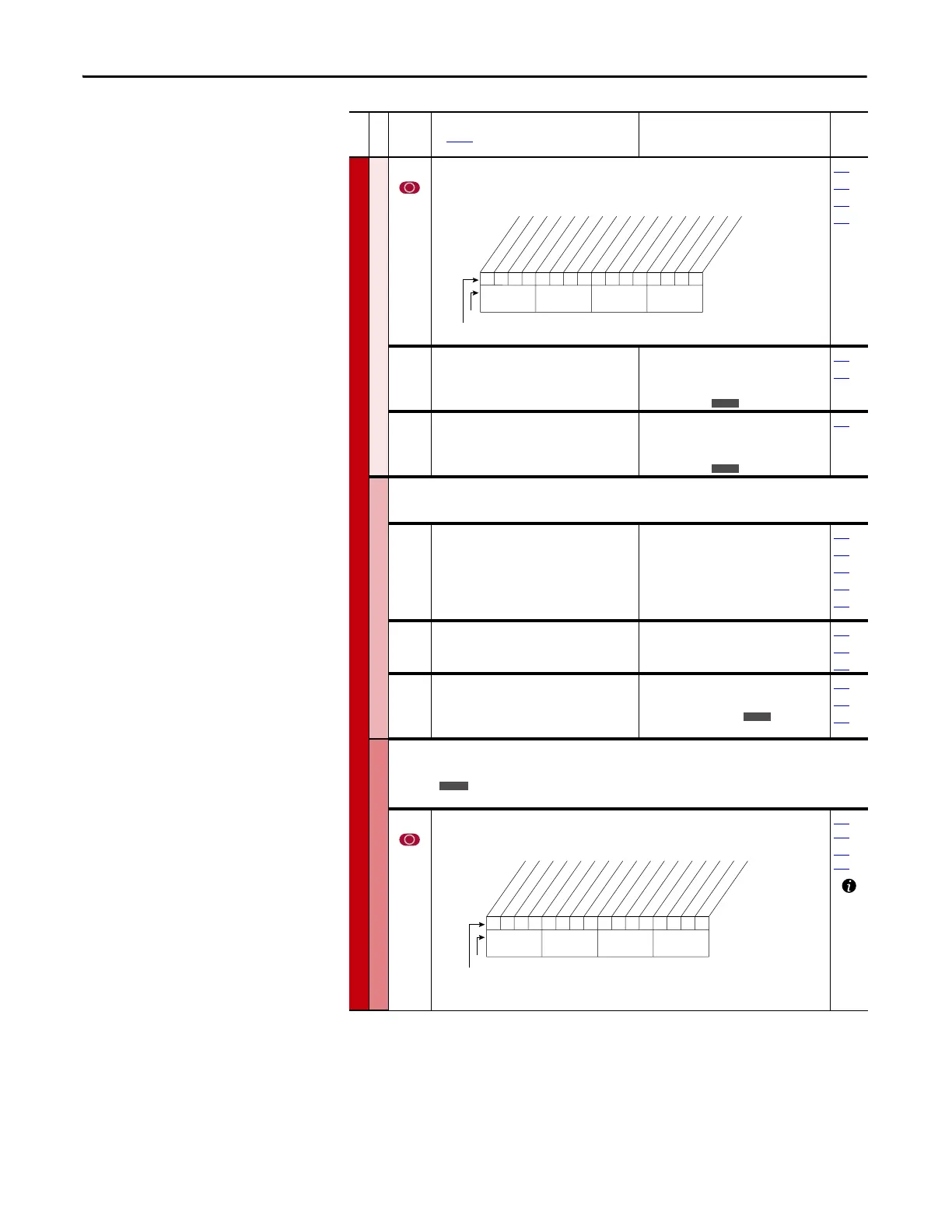

124 [PI Configuration]

Sets configuration of the PI regulator.

124

…

138

140…

143

File C

Group

No.

Parameter Name and Description

See page 14 for symbol descriptions

Values

Related

00x 0xxxxxxxxxxxx

10 01234567891112131415

1=Trimmed

0=Not Trimmed

x =Reserved

Bit #

* Enhanced Control Option Only.Factory Default Bit Values

Trim Ref A

Trim Ref B

Add or % *

Nibble 1Nibble 2Nibble 3Nibble 4

E C

E C

E C

0000000000xxxxxx

10 01234567891112131415

1=Enabled

0=Disabled

x =Reserved

Bit #

Factory Default Bit Values

Excl Mode

Invert Error

Preload Mode

Ramp Ref

Zero Clamp

Feedbak Sqrt

Stop Mode

(1)

Anti-Wind Up

(1)

Torque Trim

(2)

% of Ref

(2)

Nibble 1Nibble 2Nibble 3Nibble 4

(1)

Enhanced firmware 1.001 & later.

(2)

Enhanced firmware 2.001 & later.

Loading...

Loading...