2-6 Component Test Procedures

If the drive fails any of these measurements, replace the appropriate

Rectifying Module.

4. Conduct forward and reverse biased diode tests on the Output Power

Modules.

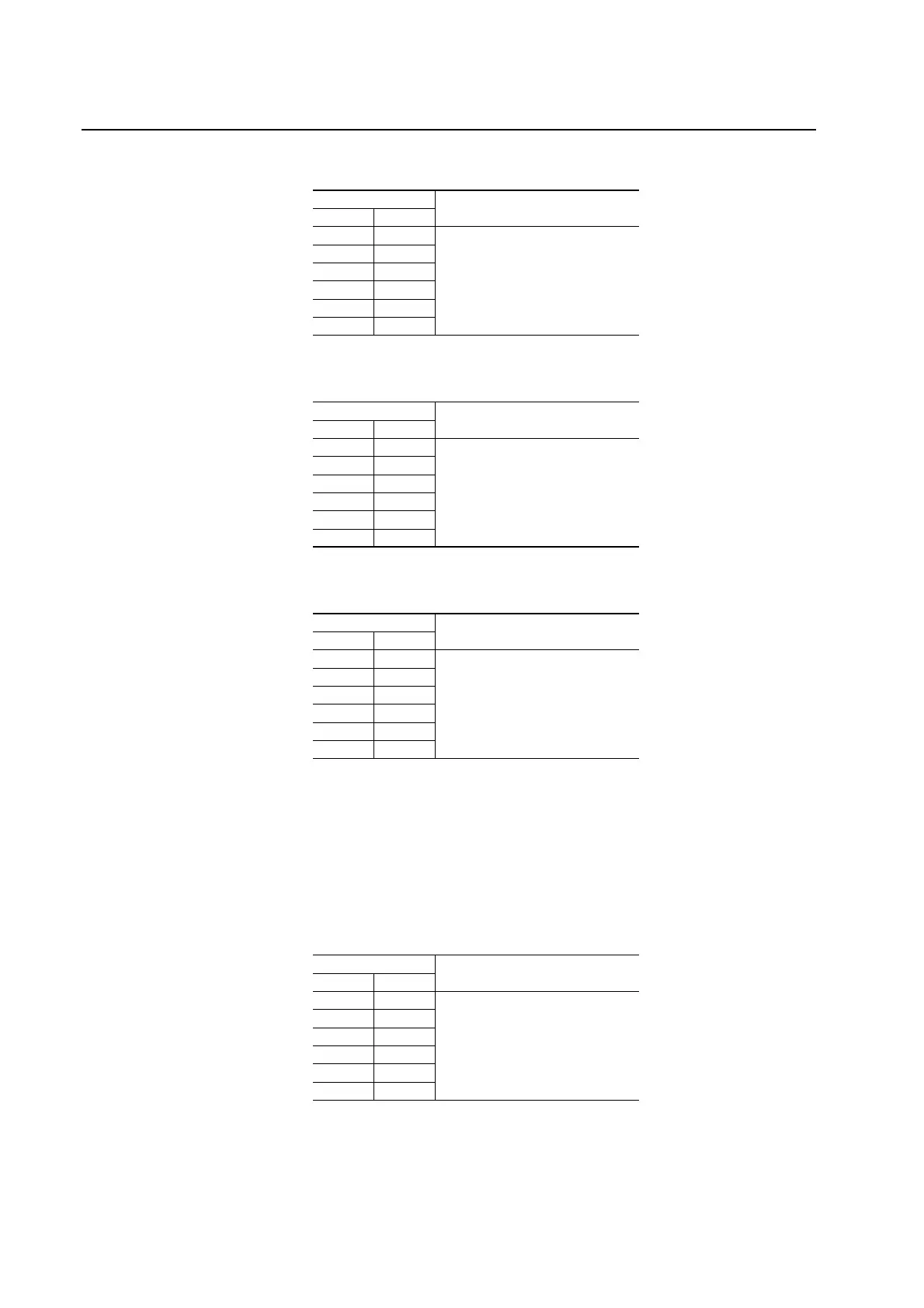

Table 2.B Forward Biased Diode Tests on Rectifying Module for Power Structure #2

Meter Leads

Nominal meter reading-+

DC+/R+

(1)

(1)

If the drive does not contain the brake chopper option, the DC+/R+

terminal will be labeled DC+.

2L1

Meter should beep once and value

should gradually rise to about 0.5V

DC+/R+ 2L2

DC+/R+ 2L3

2L1 DC-

2L2 DC-

2L3 DC-

Table 2.C Reverse Biased Diode Tests on Rectifying Module for Power Structure #1

Meter Leads

Nominal meter reading+-

1L1 DC-

Meter should display “.0L” (zero load)

1L2 DC-

1L3 DC-

DC+/R+

(1)

(1)

If the drive does not contain the brake chopper option, the DC+/R+

terminal will be labeled DC+.

1L1

DC+/R+ 1L2

DC+/R+ 1L3

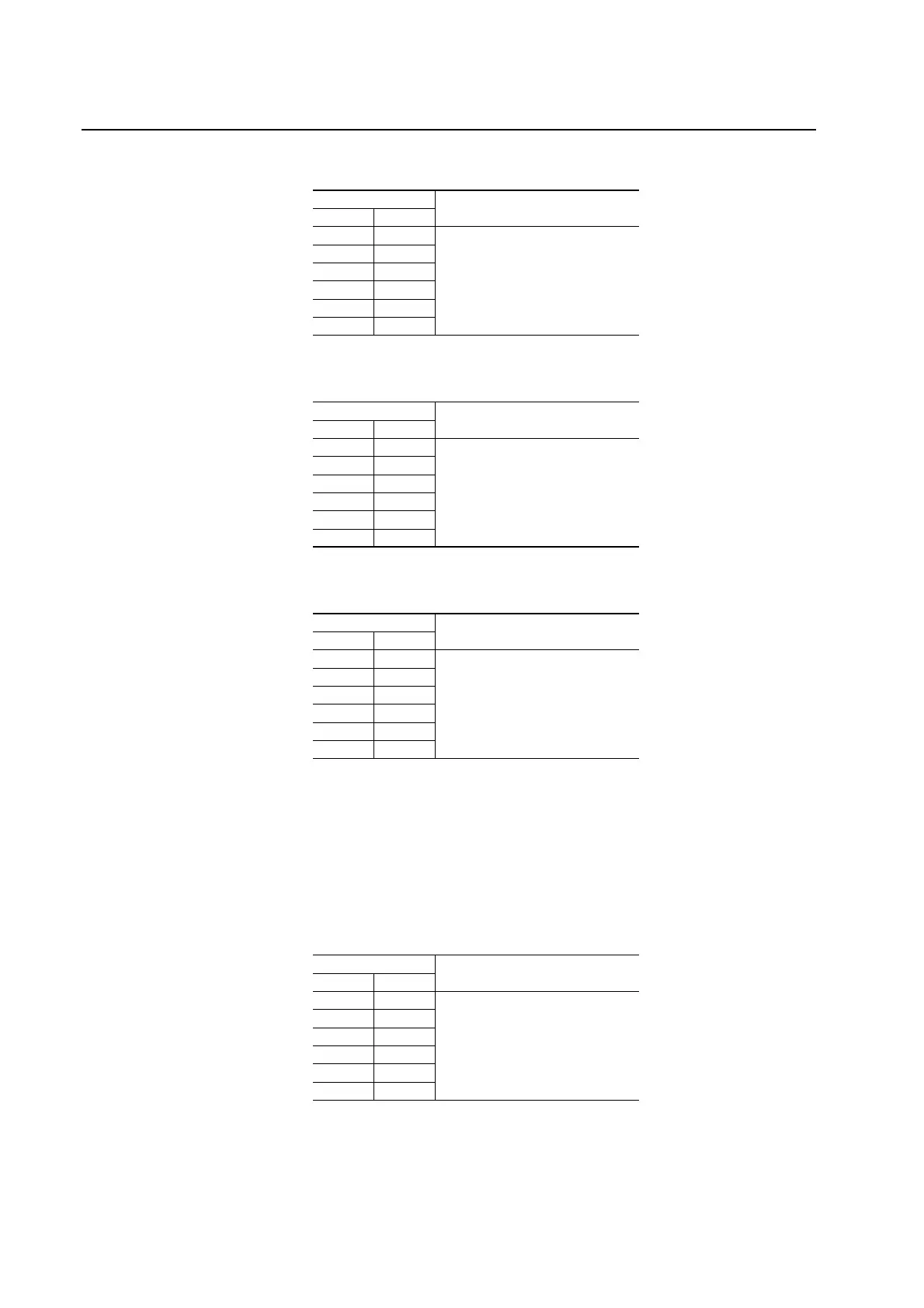

Table 2.D Reverse Biased Diode Tests on Rectifying Module for Power Structure #2

Meter Leads

Nominal meter reading+-

2L1 DC-

Meter should display “.0L” (zero load)

2L2 DC-

2L3 DC-

DC+/R+

(1)

(1)

If the drive does not contain the brake chopper option, the DC+/R+

terminal will be labeled DC+.

2L1

DC+/R+ 2L2

DC+/R+ 2L3

Table 2.E Forward Biased Diode Tests on Output Power Modules for Power Structure

#1

Meter Leads

Nominal meter reading+-

DC- 1U/T1

Meter should display “.0L” (zero load)

DC- 1V/T2

DC- 1W/T3

1U/T1 DC+/R+

(1)

(1)

If the drive does not contain the brake chopper option, the DC+/R+

terminal will be labeled DC+.

1V/T2 DC+/R+

1W/T3 DC+/R+

Loading...

Loading...