318 Rockwell Automation Publication MOTION-RM003I-EN-P - February 2018

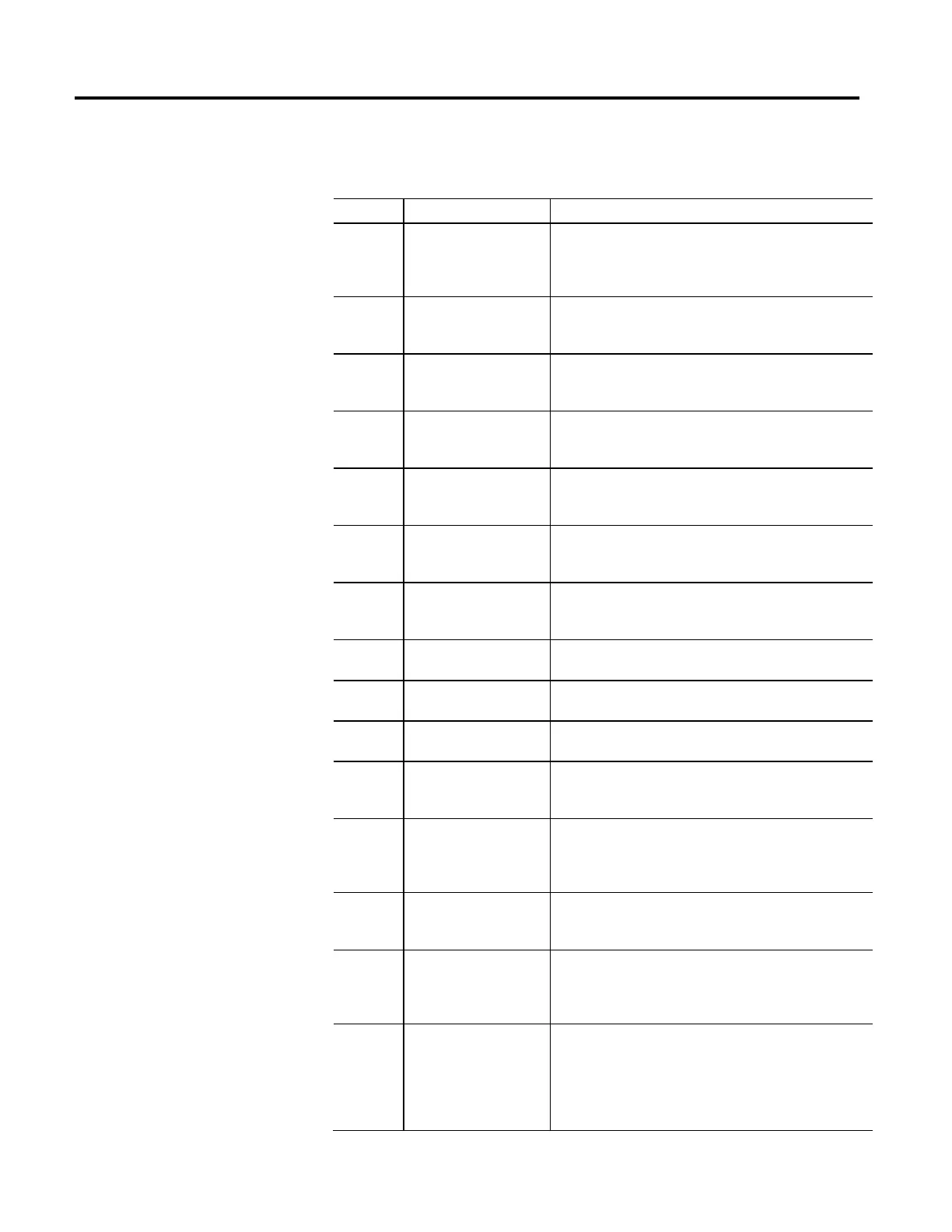

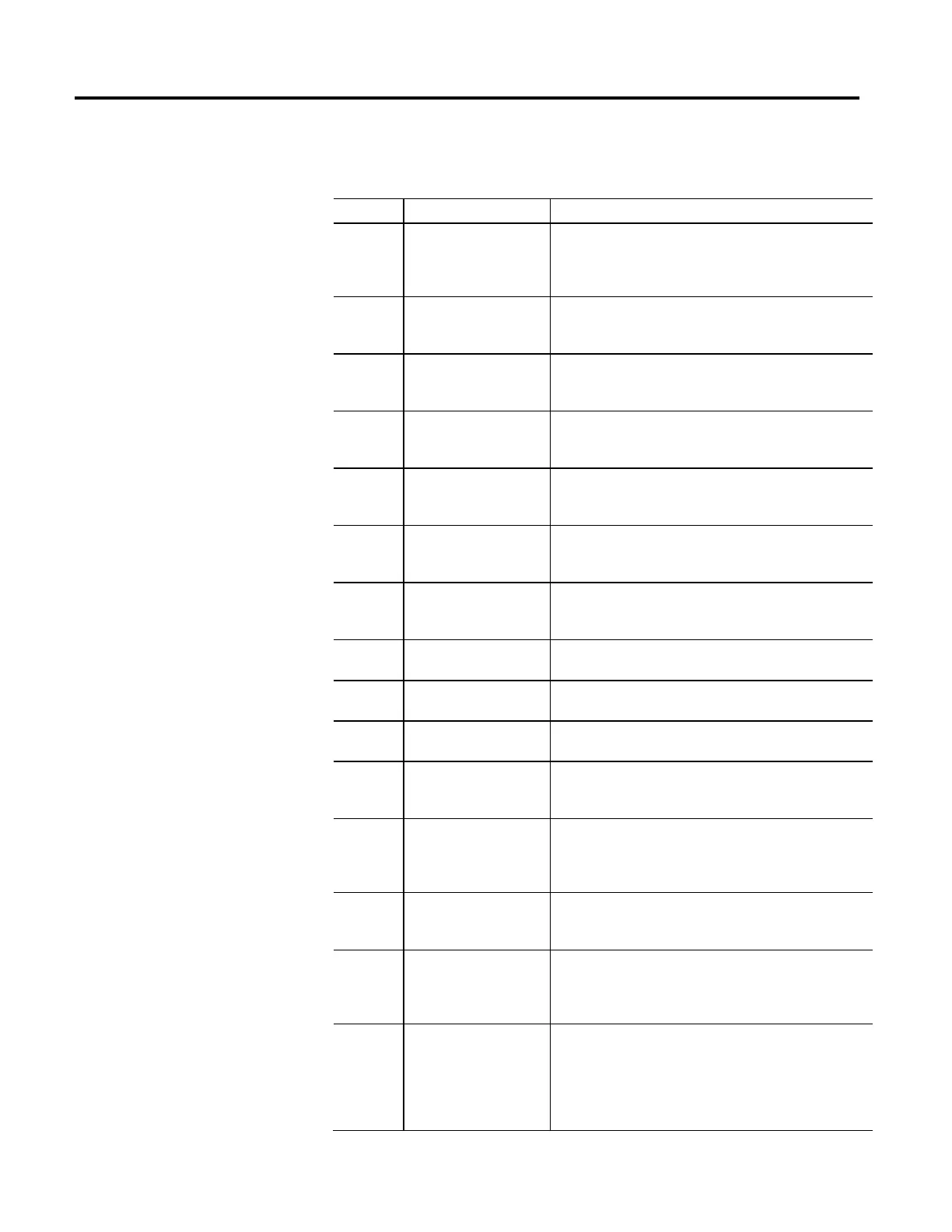

The following table provides descriptions of the bit specified Axis feature attribute

values.

Bit Motion Status Description

0 Fine Interpolation (O)

Indicates that the axis supports fine interpolation of command data

based on command target time. Fine interpolation is used to provide

smoother command reference signals when the drive update period is

smaller than the controller update period.

1 Registration Auto-rearm (O)

Indicates that the axis supports the automatic re-arming mechanism for

registration inputs. This feature is required for windowed registration

support.

2 Alarm Log (O)

Indicates that this axis supports the Alarm Log feature. Alarm Log data is

received from the drive using the Alarm bit of the Status Data Set and

updates the Alarm Log of the controller.

3 Marker (O)

Indicates that the axis position feedback device supports a marker

function. This functionality is required for Homing Sequences that

employ the marker signal and for the marker Hookup Test.

4 Home Switch (O)

Indicates that the axis supports a home switch input. This functionality is

required for Homing Sequences that employ the home switch input

signal.

5 Hookup Test (O)

The axis supports a Hookup Test service. This service is required to

perform a Hookup Test (MRHD) to check wiring to the motor and

feedback components.

6 Commutation Test (O)

The axis supports a Commutation Test as part of the Hookup Test service.

This service is required to perform a Hookup Test (MRHD) to check

commutation wiring and determine the Commutation Offset.

7 Motor Test (O)

The axis supports a Motor Test service. This service is required to perform

a Motor Test (MRMT) to measure motor model parameters.

8 Inertia Test (O)

The axis supports an Inertia Test service. This service is used as part of the

Auto Tune (MRAT) that measures inertia.

9 Sensorless Control (O)

The axis supports sensorless control operation letting the drive run in

velocity loop mode without an external feedback device.

10 Drive Scaling (O)

The device supports Drive Scaling functionality where the device is able

to scale feedback counts to planner counts and manage absolute

position.

11 Extended Event Block (O)

The device supports the extended Event Data Block format. This format

supports additional features generally associated with Drive Scaling

functionality, such as Watch Position events and Windowed

Registration.

12 Integer Command Position (O)

The device requires Command Position Format to be a DINT (32-bit

signed integer) data type. If not set, the device supports the standard

LREAL (64-bit floating point) Command Position data type.

13 Ext. Motor Text (O)

The device supports the extended motor data format for the Motor Test

service. This format supports transfer of vendor specific motor

parameters and is required for the Motor Test service to support IPM

motors.

14 Control Mode Change (O)

The device supports changes to the Control Mode while in the Running

state without generating large motion disturbances (bumpless). An

example of such a mode change would be to switch from Position

Control to Torque Control using an SSV instruction. If a particular Control

Mode change is not supported by the device, a Configuration Fault will

be generated.

Loading...

Loading...