Rockwell Automation Publication MOTION-RM002H-EN-P-February 2018 129

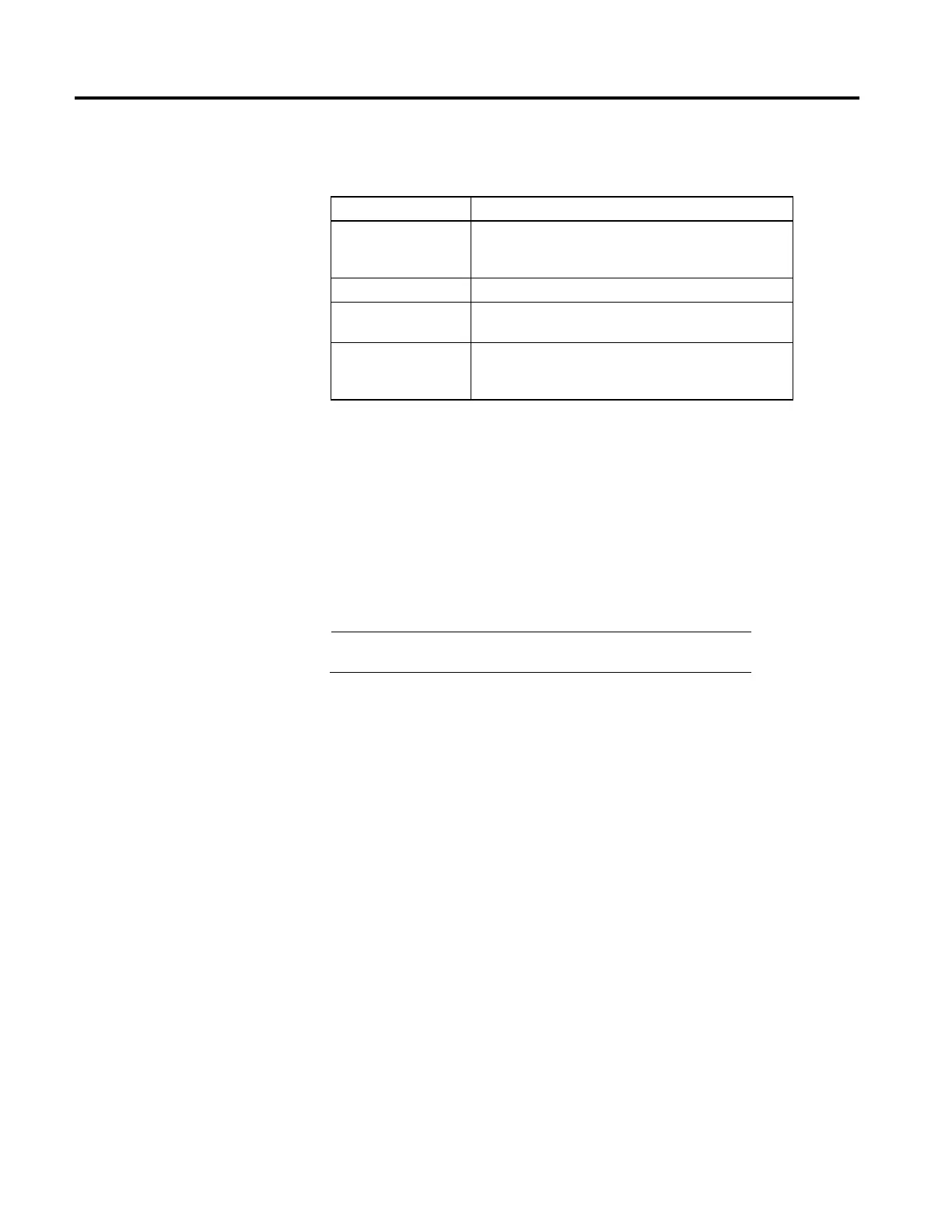

MOTION_INSTRUCTION Structure

Mnemonic Description

.EN (Enable) Bit 31 It is set when the rung makes a false-to-true transition and remains set

until the servo message transaction is completed and the rung goes

false.

.DN (Done) Bit 29 It is set when axis gear has been successfully initiated.

.ER (Error) Bit 28 It is set to indicate that the instruction detected an error, such as if you

specified an unconfigured axis.

.IP (In Process) Bit 26 It is set on positive rung transition and cleared if either superseded by

another Motion Gear Axes command, or terminated by a stop command,

merge, shutdown, or servo fault.

Description

The MAG instruction enables electronic gearing between two axes at a specified

ratio. Electronic gearing allows any physical axis to be synchronized to the actual

or command position of another physical axis at a precise ratio. It provides a direct

edge-to-edge lock between the two axes—no maximum velocity, acceleration, or

deceleration limits are used. The speed, acceleration, and deceleration of the slave

axis is completely determined by the motion of the master axis and the specified

gear ratio.

Important:

The maximum velocity, acceleration, or deceleration limits established

during axis configuration do not apply to electronic gearing.

Select or enter the desired Master Axis, Slave Axis, and Direction and enter a value

or tag variable for the desired ratio. If an axis is dimmed (gray) or not shown in the

Slave Axis pop-up menu, the physical axis is not defined for Servo operation.

If the targeted axis does not appear in the list of available axes, the axis has not

been configured for servo operation. Use the Tag Editor to create and configure a

new axis.

Electronic gearing remains active through any subsequent execution of jog, or

move processes for the slave axis. This allows electronic gearing motions to be

superimposed with jog, or move profiles to create complex motion and

synchronization.

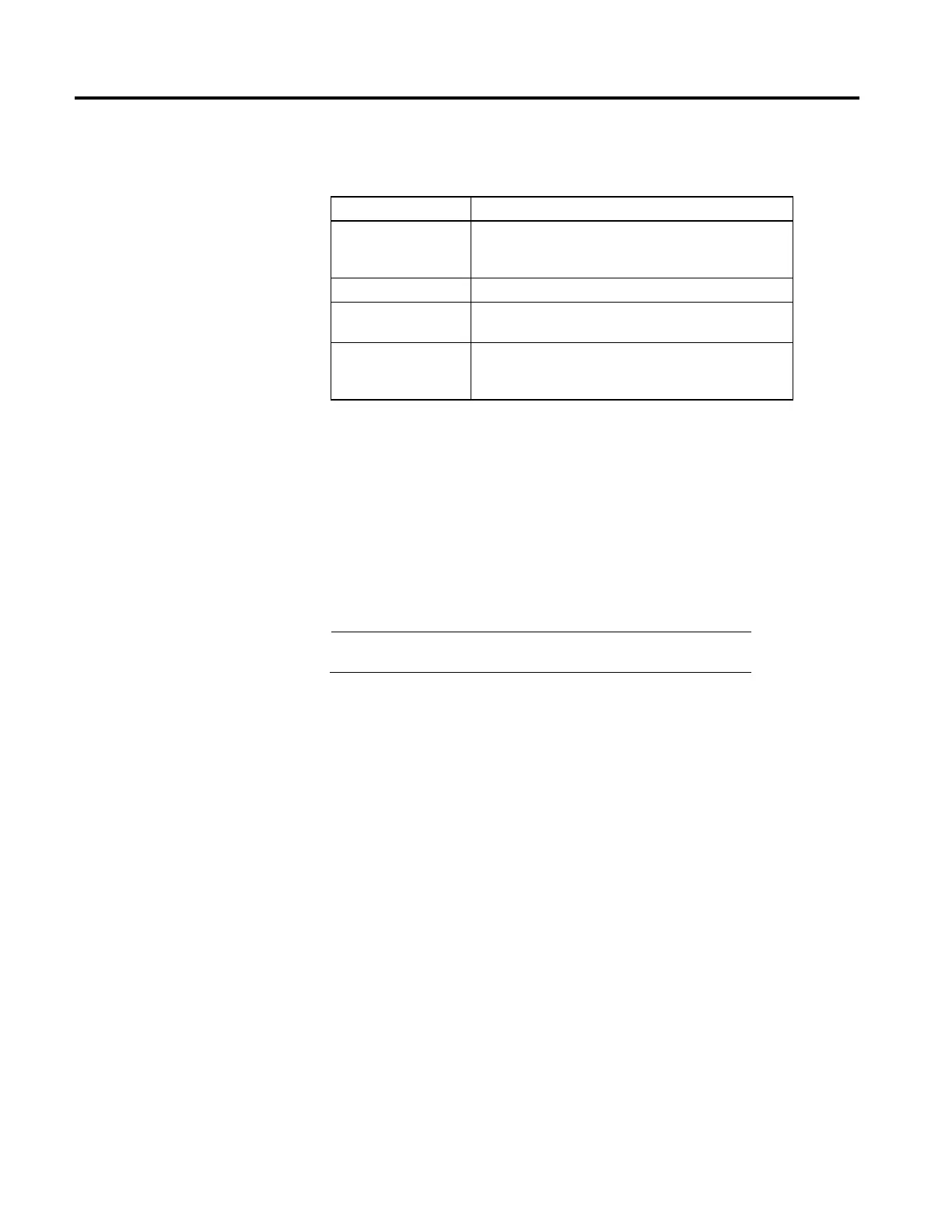

Slaving to the Actual Position When Actual Position is entered or selected as the

Master Reference source, the slave axis motion is generated from the actual

position of the master axis as shown below.

Loading...

Loading...