152 Rockwell Automation Publication MOTION-RM002H-EN-P-February 2018

Actual Position When Actual is selected or entered as the MRP Position Selection, the New Position is directly applied to the actual

position of the physical axis. The command position of the axis is also adjusted along with the new actual position to

preserve any position error which exists. This ensures that there is no unexpected motion of the axis when the

positions are redefined. See the Motion Axis Object Specification for more discussion of command position, actual

position, and position error.

Command Position When Command is selected or entered as the MRP Position Selection, the New Position is directly applied to the

command position of the servo or imaginary axis. For an axis with a Position Loop type of Feedback Only, the

Command Position and the Actual Position are the same. The MRP can be used with ether the Command or Actual

Position with the same effect. The actual position of servo axes is also adjusted along with the new command position

to preserve any position error which exists. This ensures that there is no unexpected motion of the axis when the

positions are redefined.

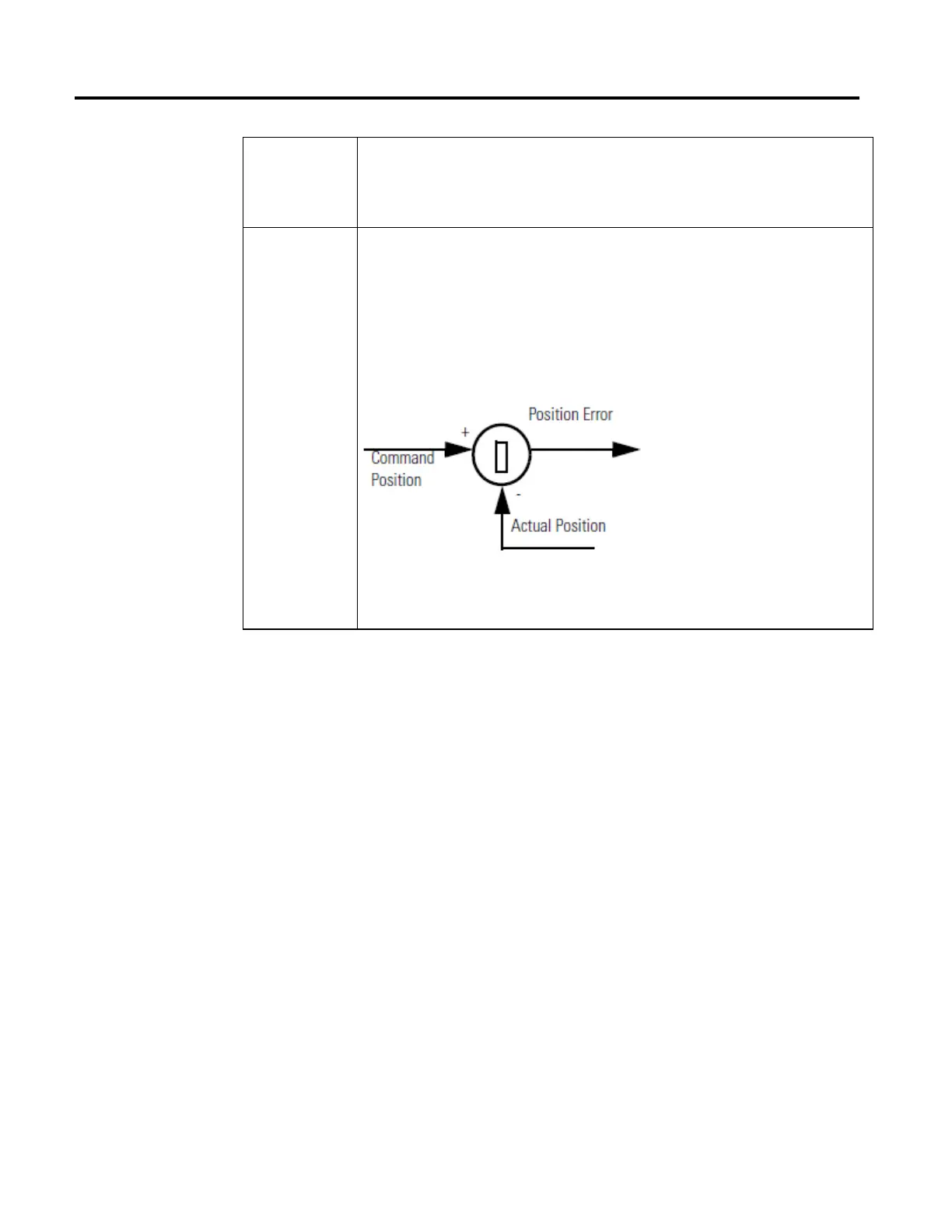

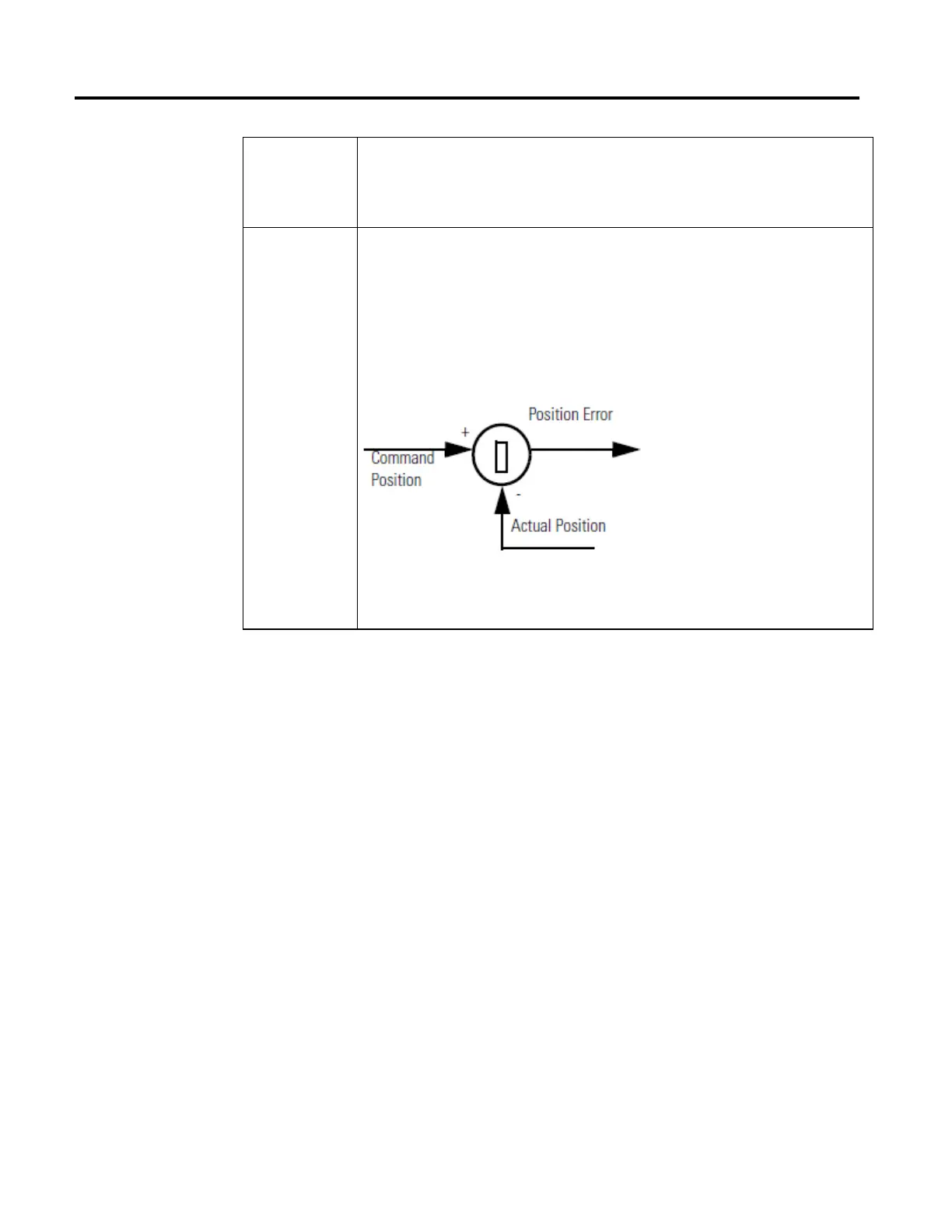

Command position is the desired or commanded position of a servo as generated by any previous motion instructions.

Actual position is the current position of a physical or virtual axis as measured by the encoder or other feedback

device. Position error is the difference between these two and is used to drive the motor to make the actual position

equal to the command position. The Figure below shows the relationship of these three positions.

To successfully execute a MRP instruction, the targeted axis must be configured as either a Servo or Feedback Only

axis. Otherwise, the instruction errs.

Important: The instruction execution may take multiple scans to execute because it requires multiple coarse updates

to complete the request. The Done (.DN) bit is not set immediately, but only after the request is completed.

In this transitional instruction, the relay ladder, toggle the Rung-condition-in

from cleared to set each time the instruction should execute.

Master Driven Speed Control (MDSC) and the MRP Instruction

You can execute an MRP on the Master or the Slave axes or coordinate system

when an MDSC is active.

The Master axis position is changed when an MRP is executed (goes IP) on the

Master while it is moving in MDSC mode; the slave is not affected.

Affects Math Status Flags

No

Major/Minor Faults

None specific to this instruction. See Common Attributes for operand-related

faults.

Loading...

Loading...