Rockwell Automation Publication MOTION-RM002H-EN-P-February 2018 177

When Continuous mode is selected, the specified cam profile, once started, is

executed indefinitely. With continuous operation, the profile’s master and slave

positions are unwound when the position of the master axis moves outside the

profile range, causing the cam profile to repeat. This feature is particularly useful

in rotary applications where it is necessary that the position cam run continuously

in a rotary or reciprocating fashion. To generate smooth continuous motion using

this technique, however, care must be taken in designing the cam points of the cam

table to ensure that there are no position, velocity, or acceleration discontinuities

between the start and end points of the calculated cam profile.

Execution Schedule

Control over the MAPC instruction’s execution is via the Execution Schedule

parameter.

Immediate Execution

By default, the MAPC instruction is scheduled to execute Immediately. In this

case, there is no delay to the enabling of the position camming process and the

Master Lock Position parameter is irrelevant. The slave axis is immediately locked

to the master axis beginning at the Cam Lock Position of the specific cam profile.

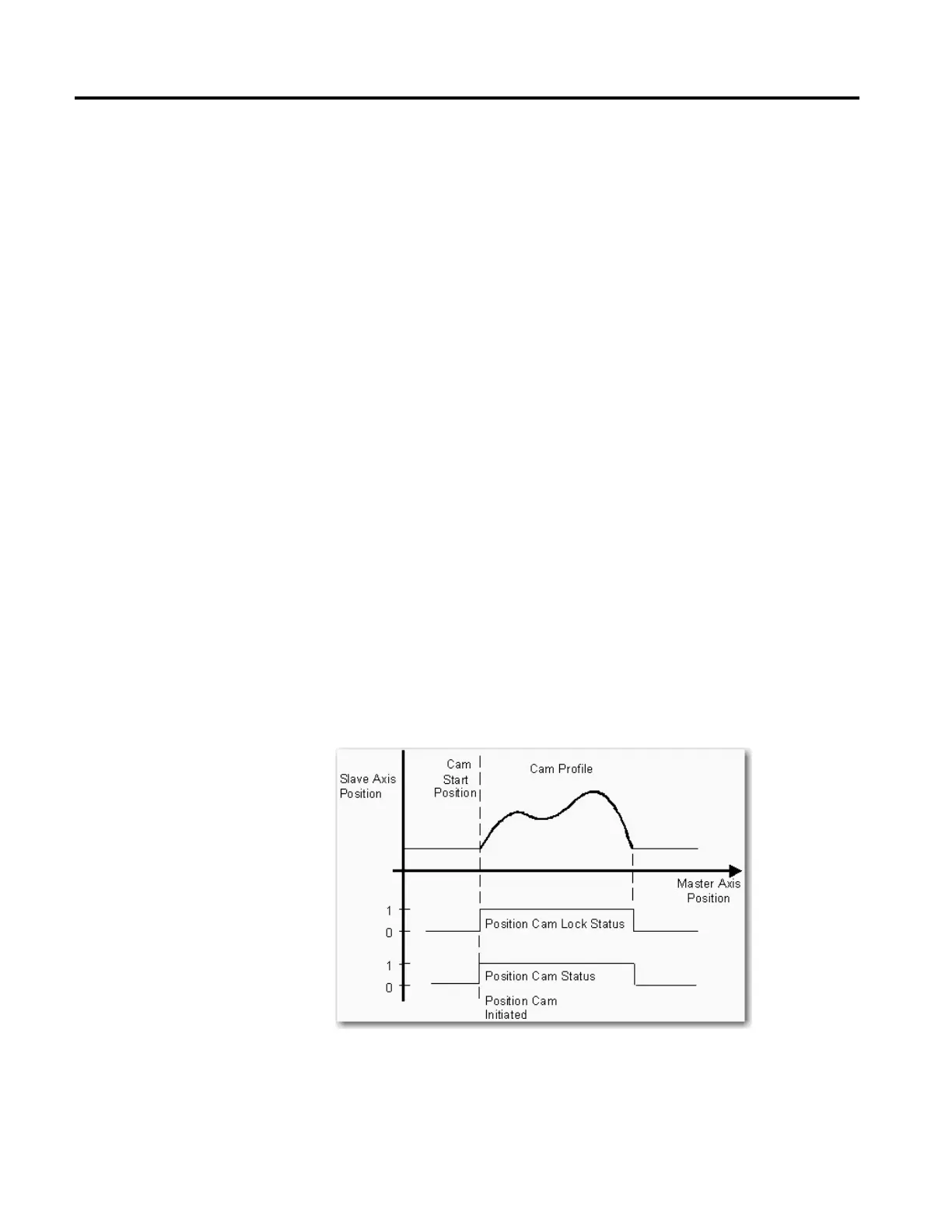

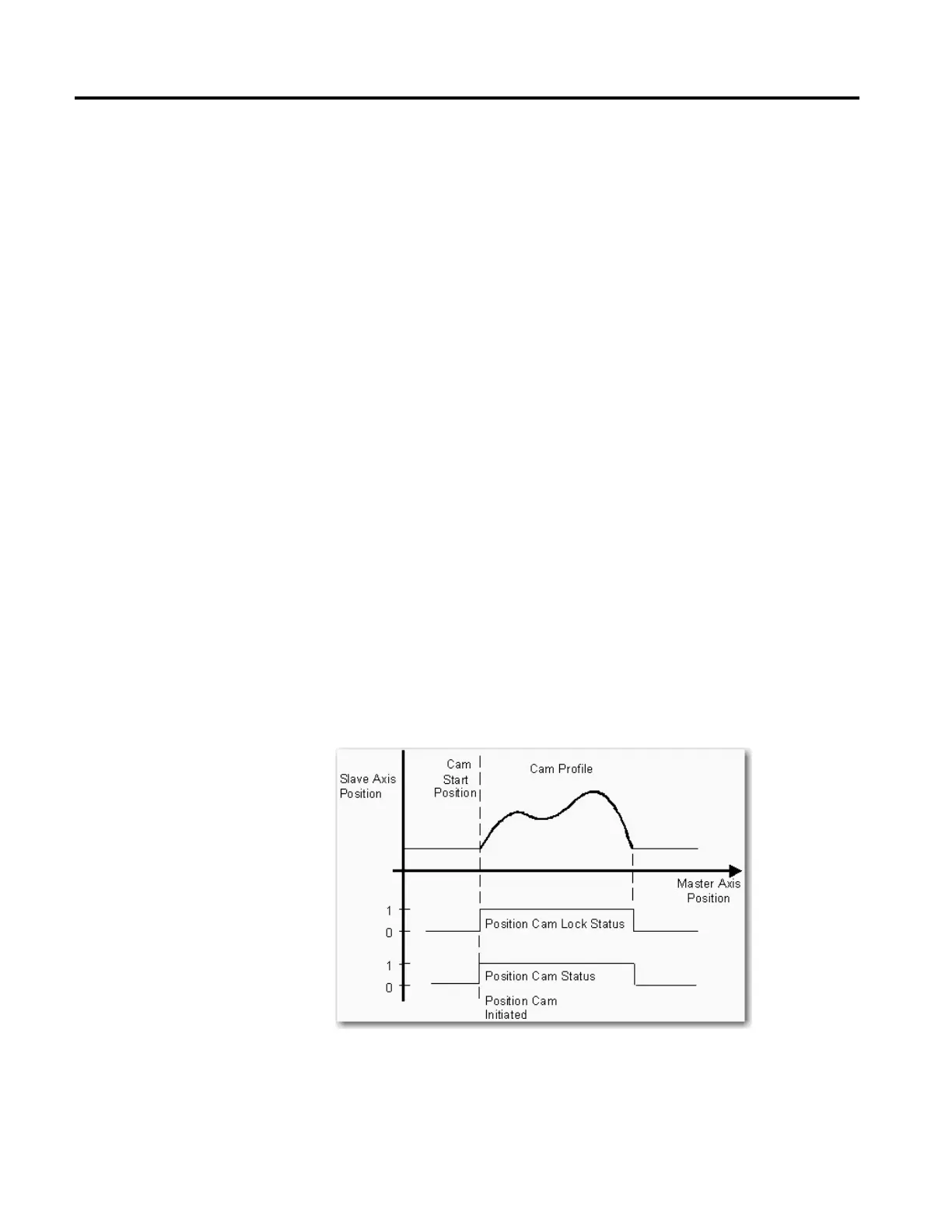

As illustrated in the diagram below, when the MAPC instruction is executed, the

camming process is initiated on the specified slave axis and the Position Cam

Status bit in the slave axis’ Motion Status word is set. If the Execution Schedule

parameter is set to Immediate, the slave axis is immediately locked to the master

according to the specified Cam Profile. This is indicated by the fact that the

Position Cam Lock Status bit for the specified slave axis is also set.

Changing the Cam Lock Position

The Cam Lock Position parameter of the MAPC instruction determines the

starting location within the cam profile when the slave locks to the master.

Loading...

Loading...