Rockwell Automation Publication MOTION-RM002H-EN-P-February 2018 179

Important: If the position reference of the master axis is redefined (for example an MRP instruction) after the MAPC

instruction executes but before the lock condition is satisfied, the cam profile generator monitors the

master axis based on the absolute position reference system in effect prior to the redefine position

operation.

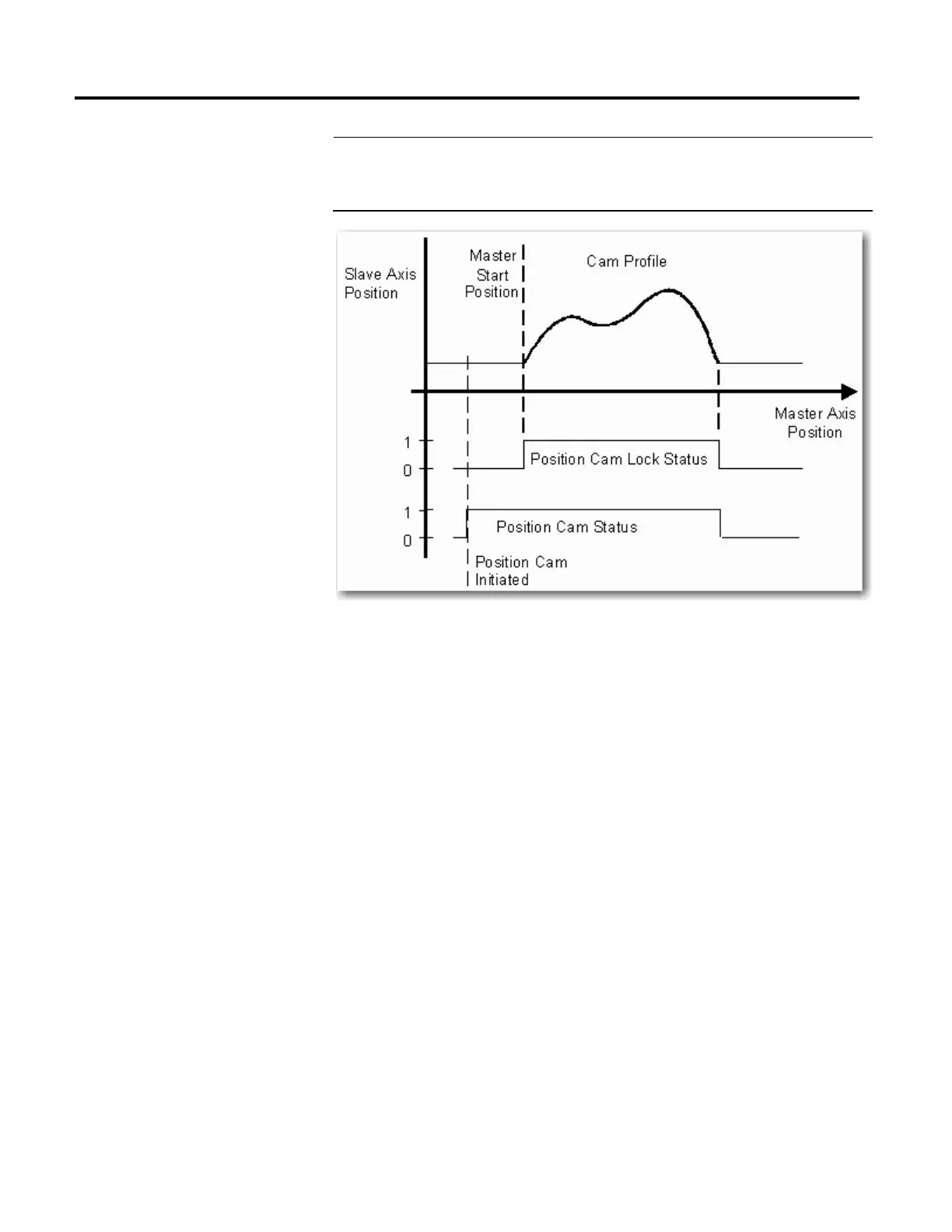

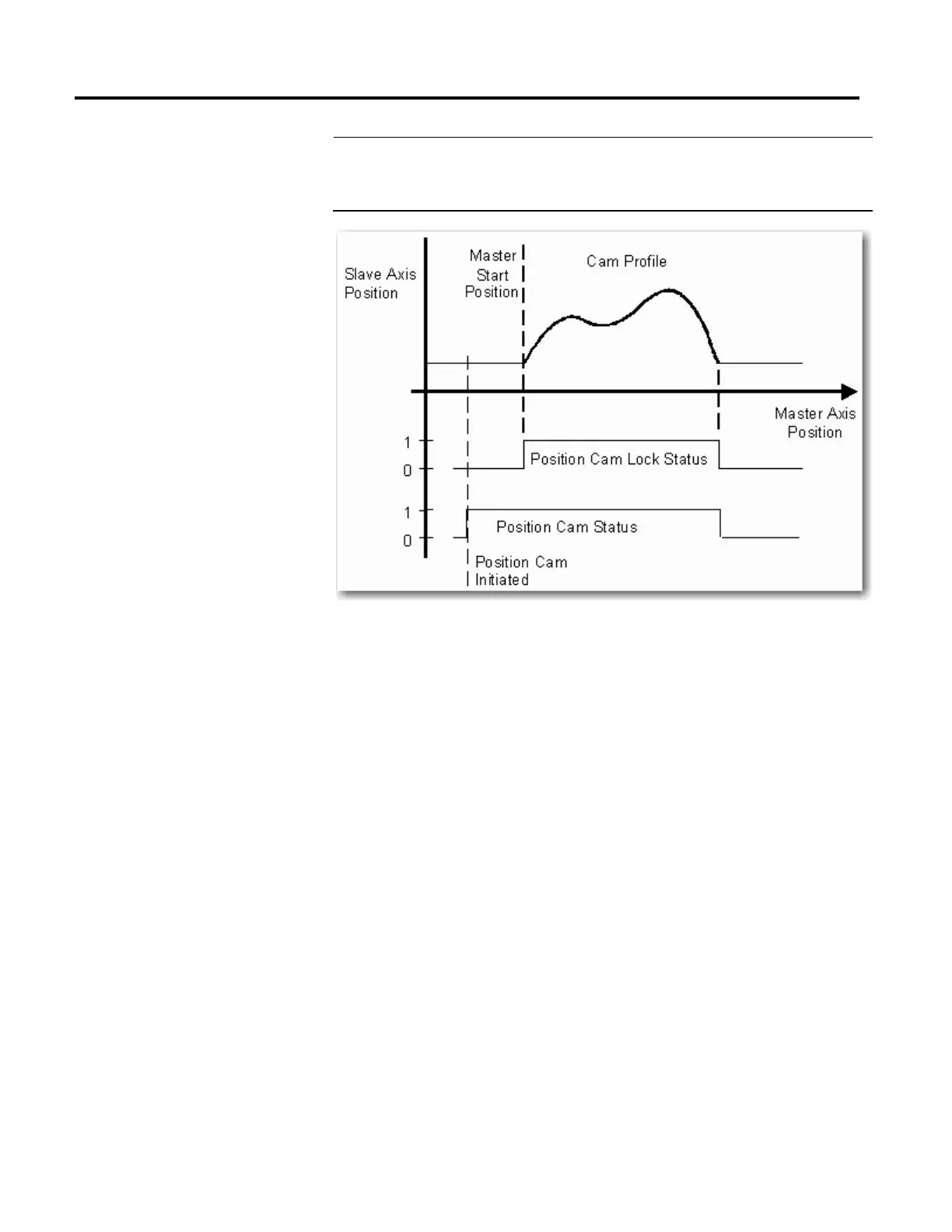

When the absolute position of the master axis passes the specified Master Lock

Position in the specified direction (Forward Only direction in the illustration

below), the Position Cam Status bit of the Motion Status word for specified slave

axis is set. Slave axis motion is then initiated according to the specified cam profile

starting at the specified Cam Lock Position of the cam profile. From this point on,

only the incremental change in the master axis position is used to determine the

corresponding slave axis position from the defined cam profile. This is important

for applications where the master axis is a rotary axis since the position cam is then

unaffected by the position unwind process.

When the master axis moves out of the range defined by the cam profile (assuming

Execution Mode configured for Once), both the Position Cam Lock Status and

the Position Cam Status bits of the Motion Status word are cleared. This Motion

Status bit condition indicates that the cam process has completed. This fact is also

reflected in the bit leg behavior of the associated MAPC instruction, PC bit set

and IP bit clear.

After position cam motion is started when the master axis passes the specified

Master Lock Position in either the Forward Only or Reverse Only direction, the

master axis can change direction and the slave axis reverses accordingly.

If an MAPC instruction is executed on a slave axis that is already actively position

camming, an Illegal Dynamic Change error is generated (error code 23). The only

exception for this is if the Execution Schedule is specified as pending.

Loading...

Loading...