Multi-Axis Coordinated Motion Instructions

396 Rockwell Automation Publication MOTION-RM002H-EN-P-February 2018

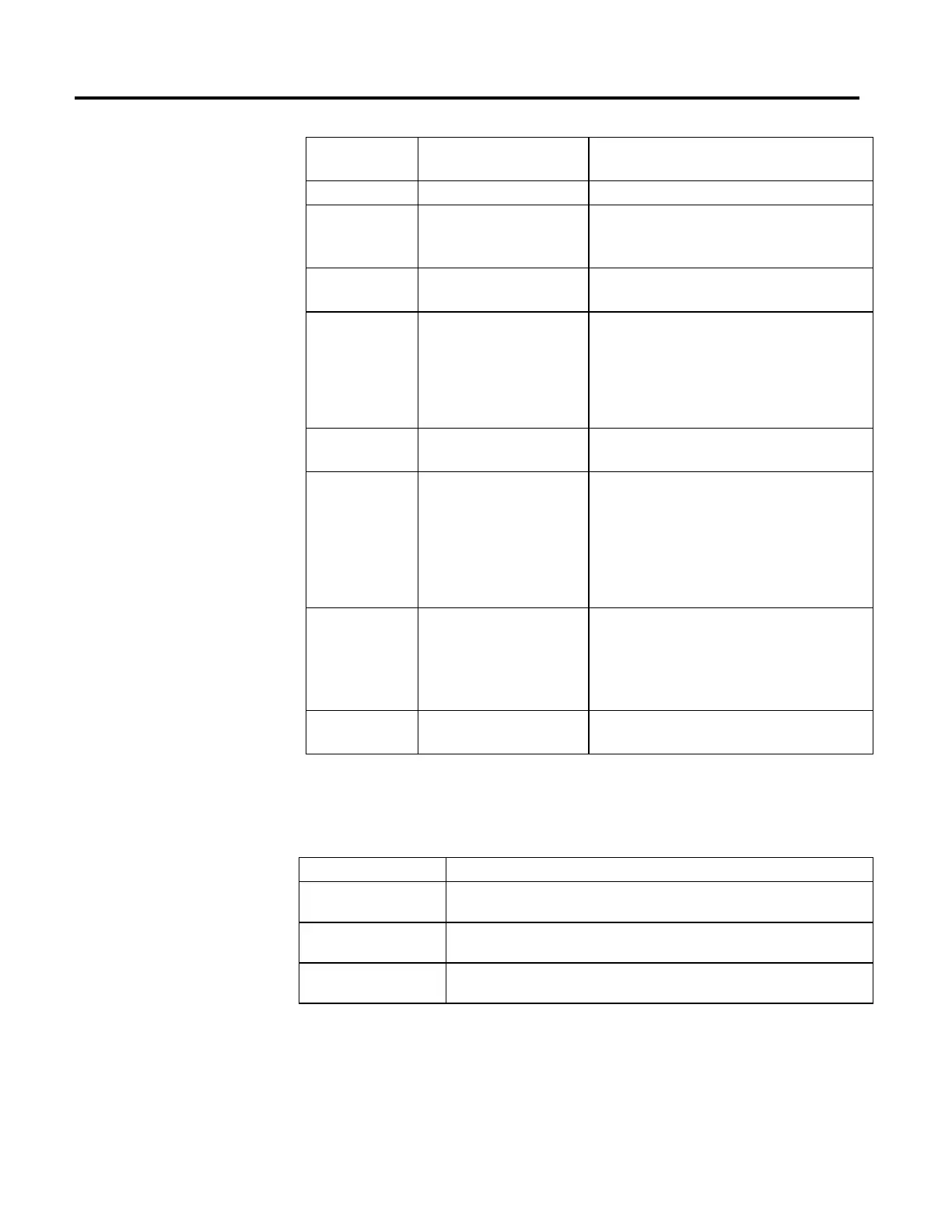

Change Decel no

yes

0 = No

1 = Yes

Decel Rate No enumeration immediate or tag

Decel Units unitspersec2

%ofmaximum

unitspermasterunit2

0

1

4

Change Accel Jerk no

yes

0 = No

1 = Yes

Accel Jerk No enumeration immediate or tag

You must always enter a value for the Accel operand. This

instruction only uses the value if the Profile is configured as

S-curve.

Use this value to get started.

Accel Jerk = 100 (% of Time)

Change Decel Jerk no

yes

0 = No

1 = Yes

Decel Jerk No enumeration immediate or tag

You must always enter a value Decel Jerk operand. This

instruction only uses the value if the Profile is configured as

S-curve.

Use this value to get started.

Decel Jerk = 100 (% of Time)

Jerk Units = 2

Jerk Units unitspersec3

%ofmaximum

%oftime

unitspermasterunit3

%oftimemasterdriven

0

1

2 (use this value to get started)

3

6

Scope activemotion

activeandpendingmotion

0 = Active Motion

1 = Active and Pending Motion

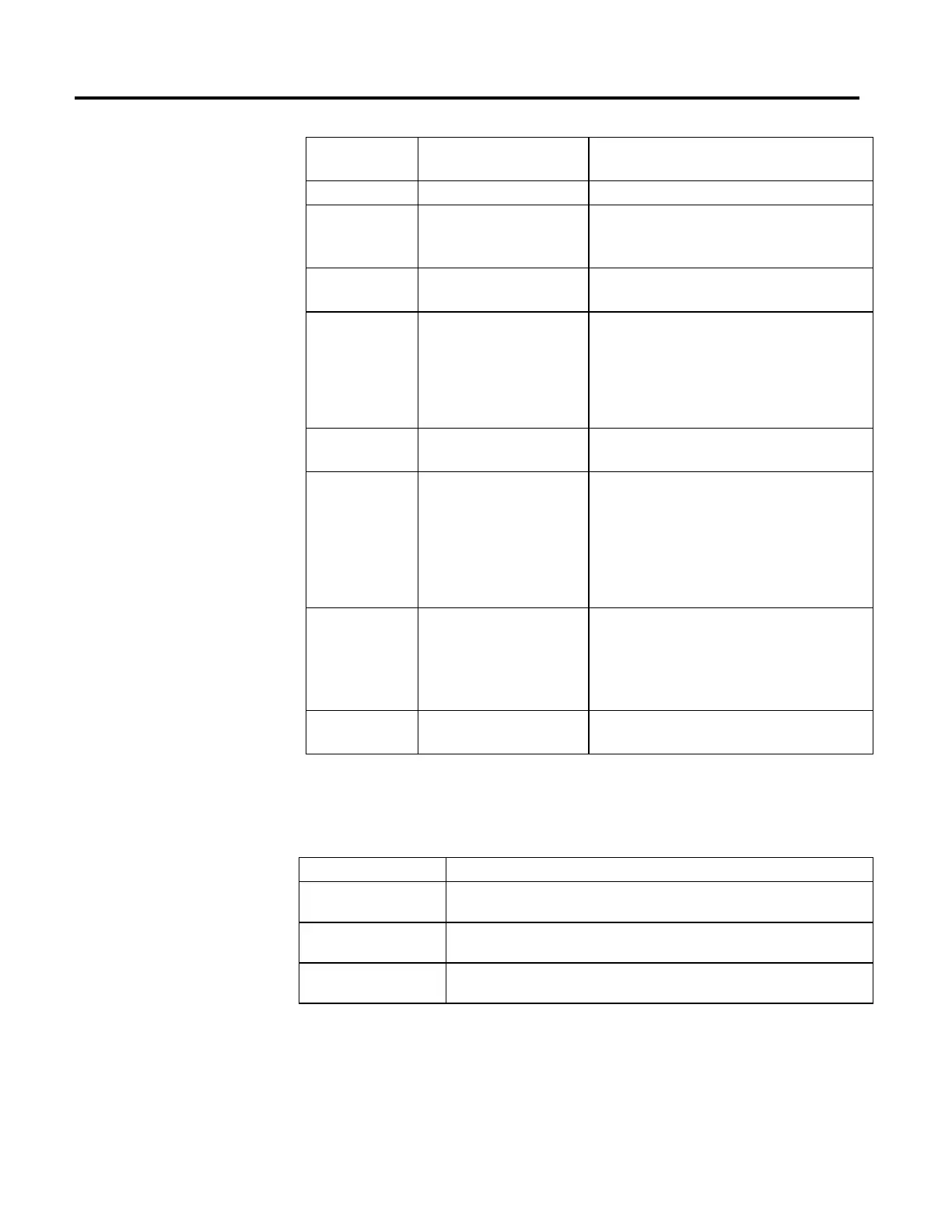

Outputs

The following table explains the instruction outputs.

Mnemonic Description

.EN (Enable) Bit 31 The Enable bit is set when the rung transitions from false to true. It resets when the rung

transitions from true to false.

.DN (Done) Bit 29 The Done bit resets when the rung transitions from false to true. It sets when target position is

calculated successfully.

.ER (Error) Bit 28 The Error bit resets when the rung transitions from false to true. It sets when target position fails

to calculate successfully.

Loading...

Loading...