Multi-Axis Coordinated Motion Instructions

440 Rockwell Automation Publication MOTION-RM002H-EN-P-February 2018

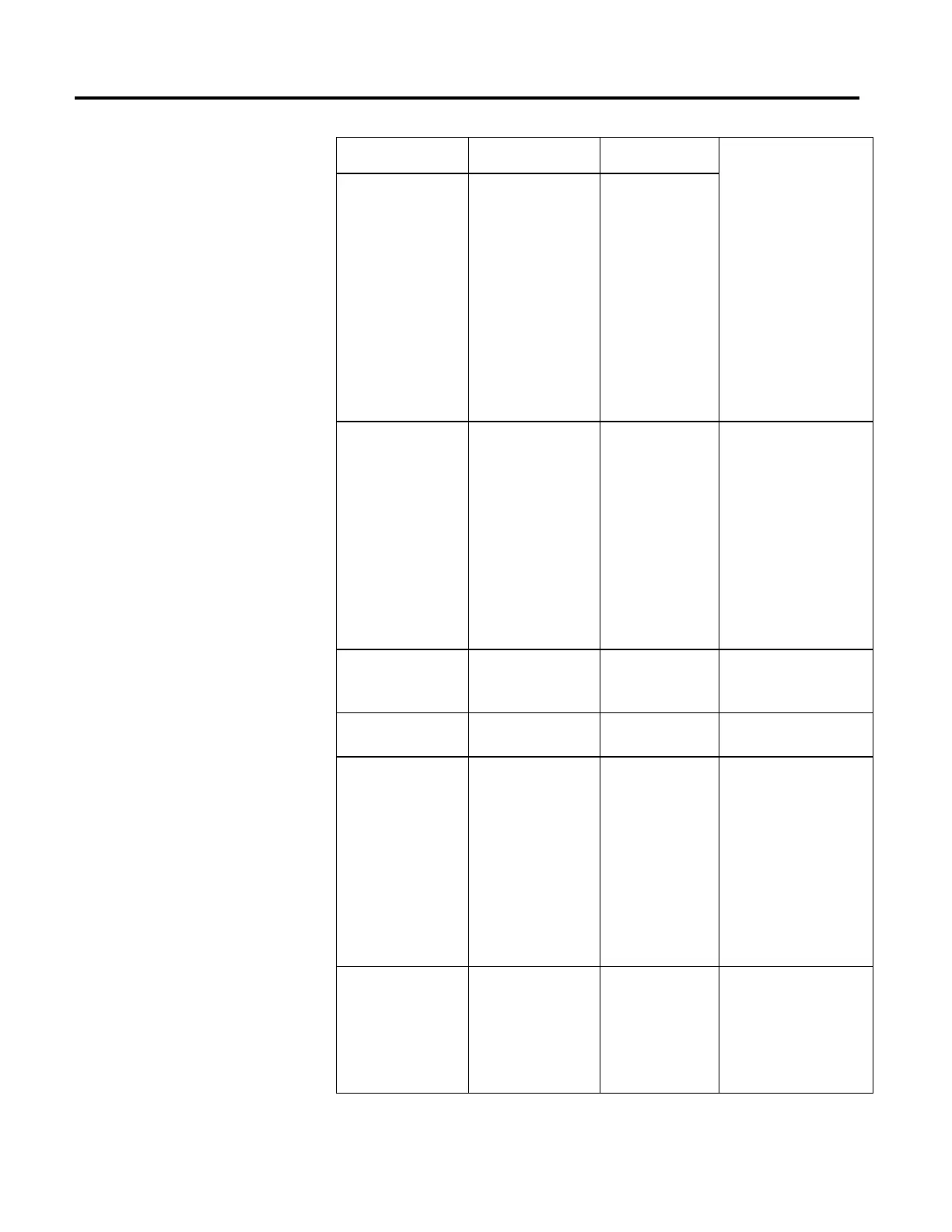

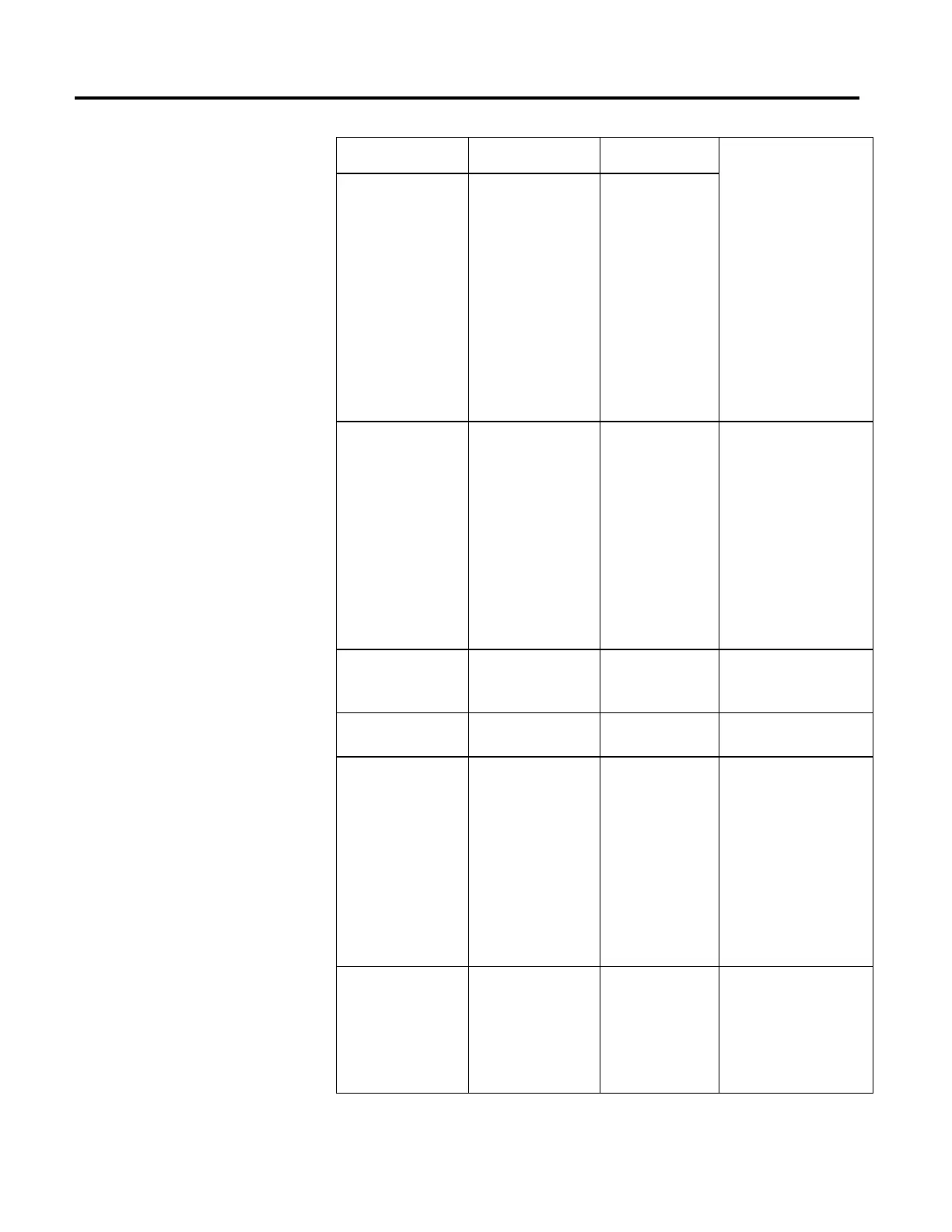

Decel Jerk SINT, INT, DINT, or REAL Immediate or Tag

operands. This instruction only

uses the values if the Profile

operand is configured as S-curve.

Enter the jerk rates in these Jerk

Units.

0 = Units per sec

3

1 = % of Maximum

2 = % of Time

4 = Units per MasterUnit

3

6 = % of Time-Master Driven

Use these values to get started.

Accel Jerk = 100 (% of Time)

Decel Jerk = 100 (% of Time)

Jerk Units = 2

Jerk Units SINT, INT, or DINT Immediate

Termination Type SINT, INT, or DINT Immediate or Tag 0 = Actual Tolerance

1 = No Settle

2 = Command Tolerance

3 = No Decel

4 = Follow Contour Velocity

Constrained

5 = Follow Contour Velocity

Unconstrained

6 = Command Tolerance

Programmed

See Choose a Termination Type in

the Related Topics section below.

Merge SINT, INT, or DINT Immediate 0 = Disabled

1 = Coordinated Motion

2 = All Motion

Merge Speed SINT, INT, or DINT Immediate 0 = Programmed

1 = Current

Command Tolerance REAL Immediate Real or Tag The position on a coordinated

move where blending should

start. This parameter is used in

place of Command Tolerance in

the Coordinate System if

Termination Type 6 is used.

Tip: Termination type 2 is

identical to Termination Type 6

except the Command Tolerance

value from the coordinate system

is used and this parameter is

ignored.

Lock Position REAL Tag Position on the Master Axis

where a Slave should start

following the master after the

move has been initiated on the

Slave Axis.

See the Structure section below

for more information.

Loading...

Loading...