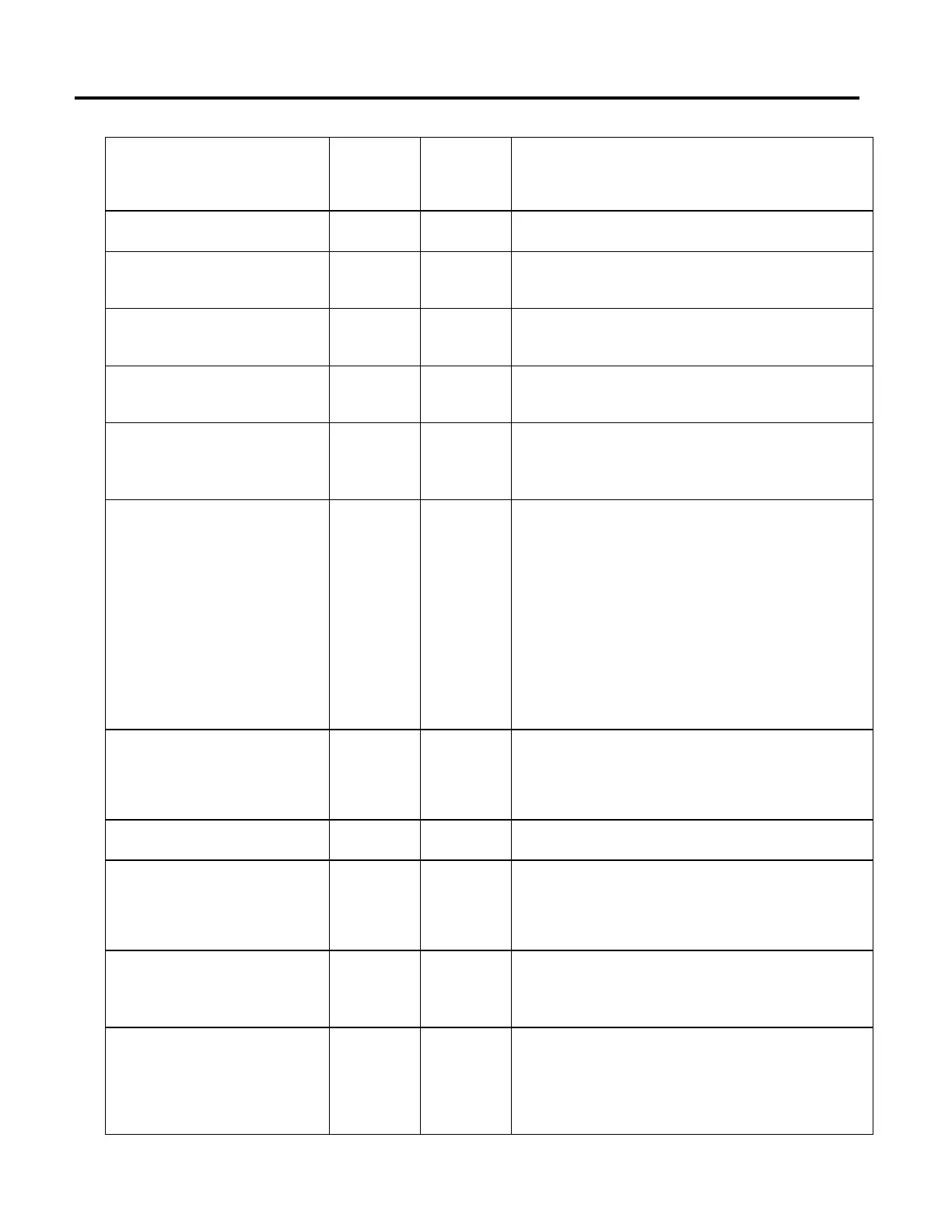

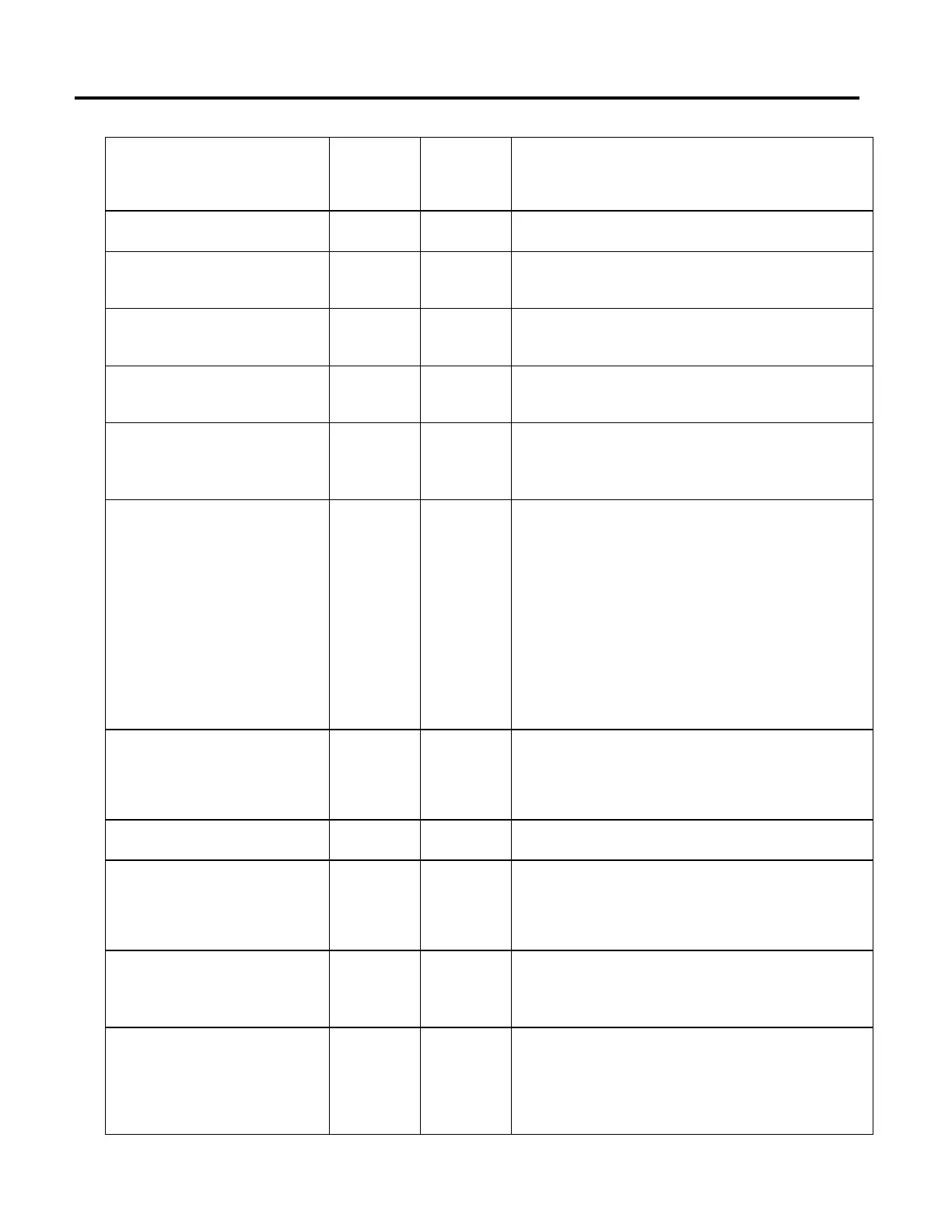

Motion Error Codes, faults, and attributes

596 Rockwell Automation Publication MOTION-RM002H-EN-P-February 2018

OutputOffset REAL GSV/SSV G9/Configuration

The fixed value used to offset the drift caused by the cumulative drive offsets of

the servo module DAC output and the servo drive input. This value added is to the

Servo Output.

PositionCommand REAL GSV G11/Status

Within the Servo Loop, this attribute is used to control the position of the axis.

PositionDataScaling INT GSV G10/Configuration

This advanced scaling attribute maps directly to the SERCOS IDNs. It is

automatically configured to the appropriate default. It is read-only

PositionDataScalingExp INT GSV G10/Configuration

This advanced scaling attribute maps directly to the SERCOS IDNs. It is

automatically configured to the appropriate default. It is read-only.

PositionDataScalingFactor DINT GSV G10/Configuration

This advanced scaling attribute maps directly to the SERCOS IDNs. It is

automatically configured to the appropriate default. It is read-only.

PositionError REAL GSV G11/Status

The difference between the actual and command position of a servo axis.

You can use this in conjunction with other error terms, to drive the motor to

where the actual position equals the command position in an active servo loop.

PositionErrorFaultAction SINT GSV/SSV G11/Configuration

Sets the type of operation performed when a position error fault occurs.

Value: Meaning:

0 = shutdown – most severe action to a fault and is reserved for faults that could

endanger machinery or personnel.

1 = disabled drive – when the fault occurs the drive is immediately disabled, the

servo output zeroed, and drive enable is output is deactivated

2 = stop command – when fault occurs the axis immediately begins decelerating

the axis command position to a stop at the configured Maximum Deceleration

Rate without disabling servo action or the servo module’s Drive Enable Output.

This is the gentlest stopping action for a fault.

3 = status only – when set to status only, motion faults must be handled by the

application program

PositionErrorTolerance REAL GSV/SSV G11/Configuration

Specifies the amount of position error that the servo/drive tolerates before issuing

a position error fault. It is interpreted as a ± quantity. A value of 0.75 position

units means that an error is generated when the position error is greater than

0.75 or less than -0.75.

PositionFeedback REAL GSV G11/Status

Represents the current position of the axis within the servo loop.

PositionIntegralGain REAL GSV/SSV G11/Configuration

Improves the steady-state performance of the system. It achieves accurate axis

positioning despite disturbances such as static friction and gravity. Increasing the

integral gain increases the ultimate positioning accuracy of the system. Increase it

too much though and you get system instability.

PositionIntegratorError REAL GSV G11/Status

The running sum of the Position Error for the specified axis.

You can use this in conjunction with other error terms, to drive the motor to

where the actual position equals the command position in an active servo loop.

PositionLockTolerance REAL GSV/SSV G11/Configuration

Specifies how much position error that the servo/SERCOS module tolerates when

giving a true position locked status indication. Used in conjunction with the

PositionLockedStatus bit, it is useful in controlling position accuracy. It is

interpreted as a ± quantity. A value of 0.01 inches means that an error is

generated when the position error is greater than 0.01 or less than -0.01

Loading...

Loading...