Service

3 - 4

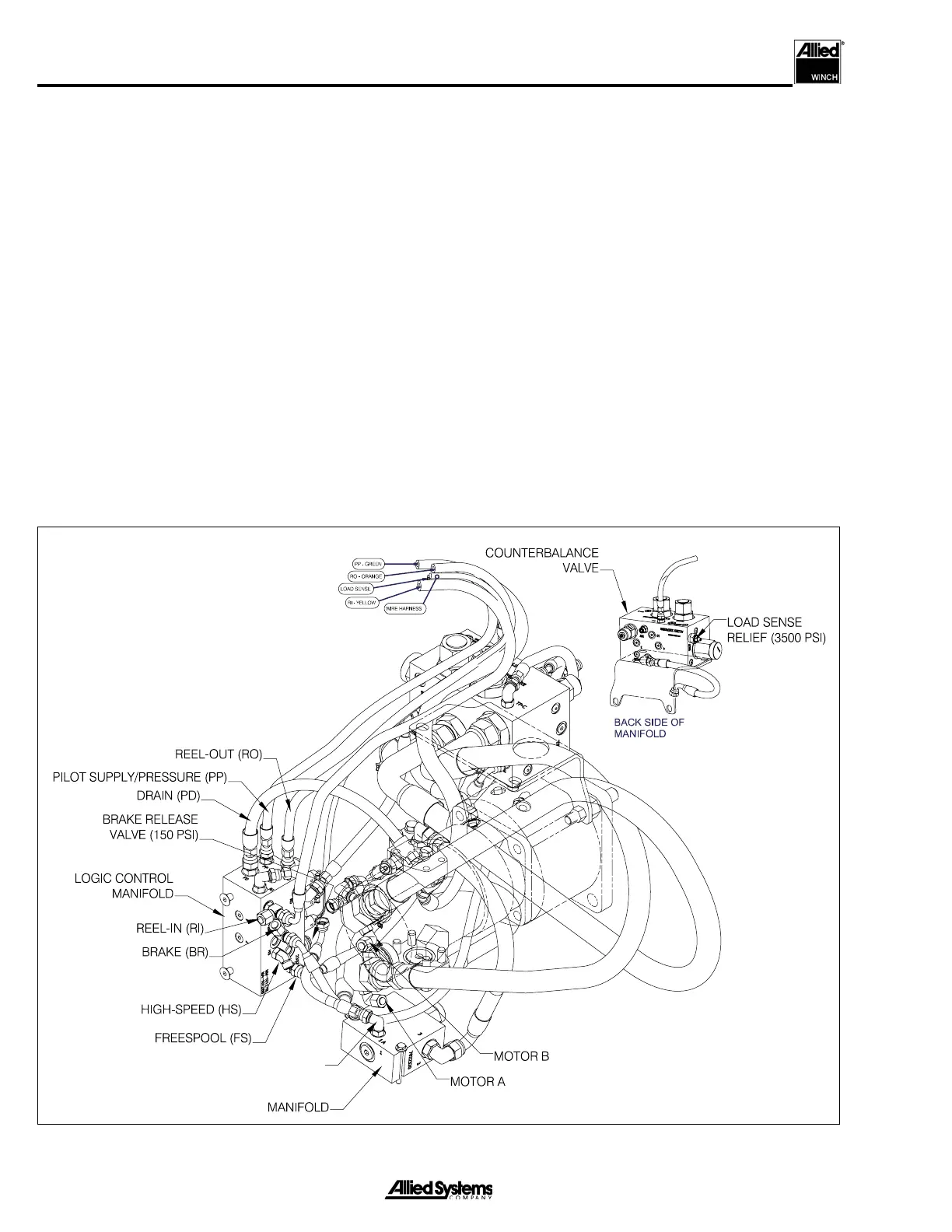

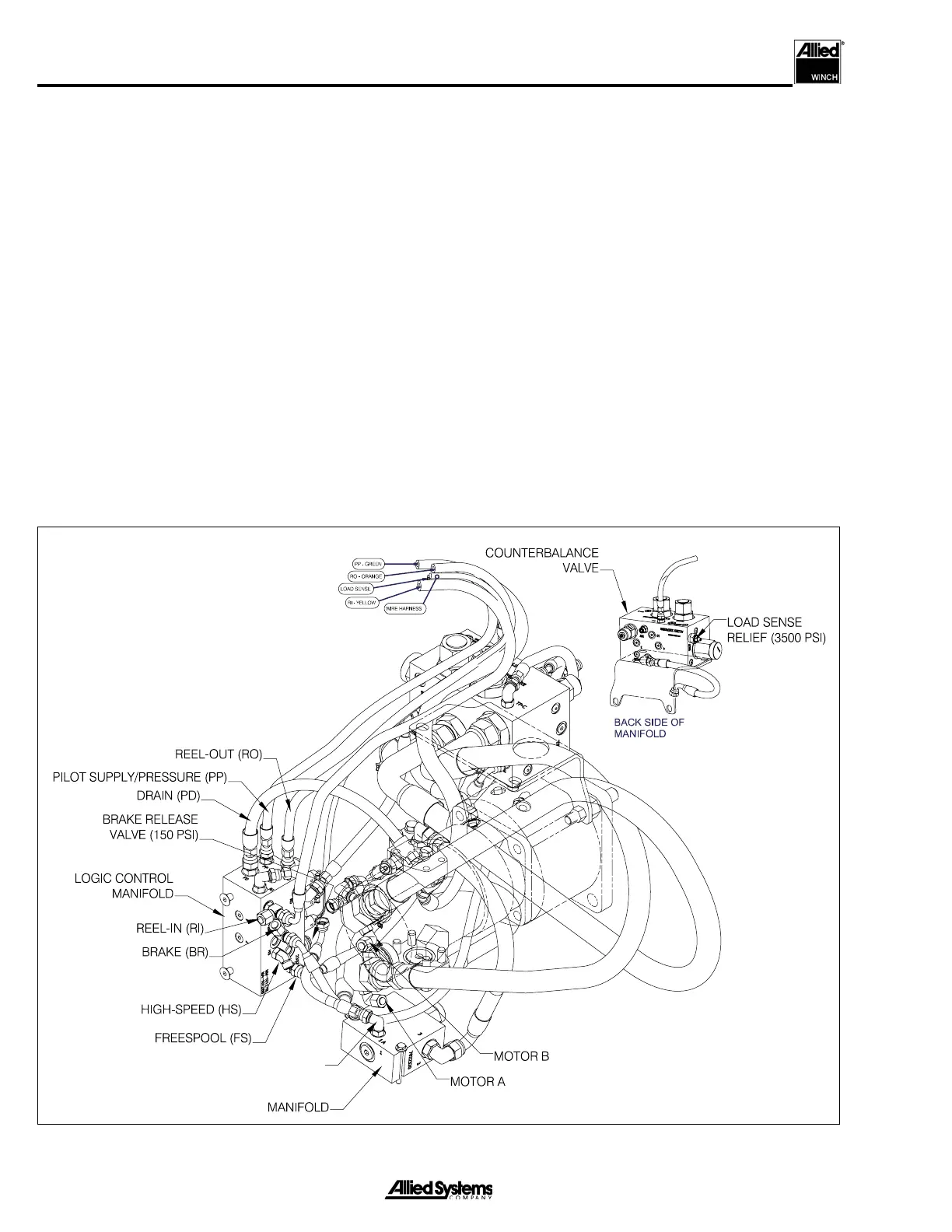

Counterbalance Valve Pressure Check

With the engine shut off, connect one 5000 psi pressure

gauge to Motor Port B. Start the engine and place han-

dlever in LINE-OUT to build pressure against the coun-

terbalance valve. Check pressure as indicated in Figure

3-6. Pressure on the B side of the motor is a ratio of the

relief setting of the counterbalance valve. If pressure is

not to specification, do not adjust valve until remaining

pressure diagnostics are performed and other problems

are identified.

Counterbalance Valve Adjustment:

1. Start engine and place handlever in LINE-OUT posi-

tion

2. Measure pressure at Motor Port B.

3. Loosen Counterbalance Valve locknut. Turn coun-

terbalance valve adjusting capscrew IN to decrease

pressure and OUT to increase pressure. Adjust pres-

sures as shown in Figure 3-6.

Motor Supply Pressure Check

With the engine shut off, connect one 5000 psi pressure

gauge to Motor Port A and one 5000 psi gauge to Motor

Port B. Disconnect and plug the brake release hose from

the brake. This will lock the winch brake to build pressure

in the motor. Check pressure as indicated Figure 3-6. If

pressure is too high, adjust the load sense relief valve. If

it is too low, proceed with pressure diagnostics to identify

other possible problems. A damaged motor or pump can

cause low pressure at the motor.

Load Sense Valve Adjustment:

1. Leave the brake pressure supply disconnected.

2. Start the engine and operate the winch in LINE-IN

or LINE-OUT.

Figure 3-5 Hydraulic Pressure Test Ports S/N H6G-1021 and above (some items removed for clarity)

BYPASS

BYPASS

Loading...

Loading...