Section 4

4 - 29

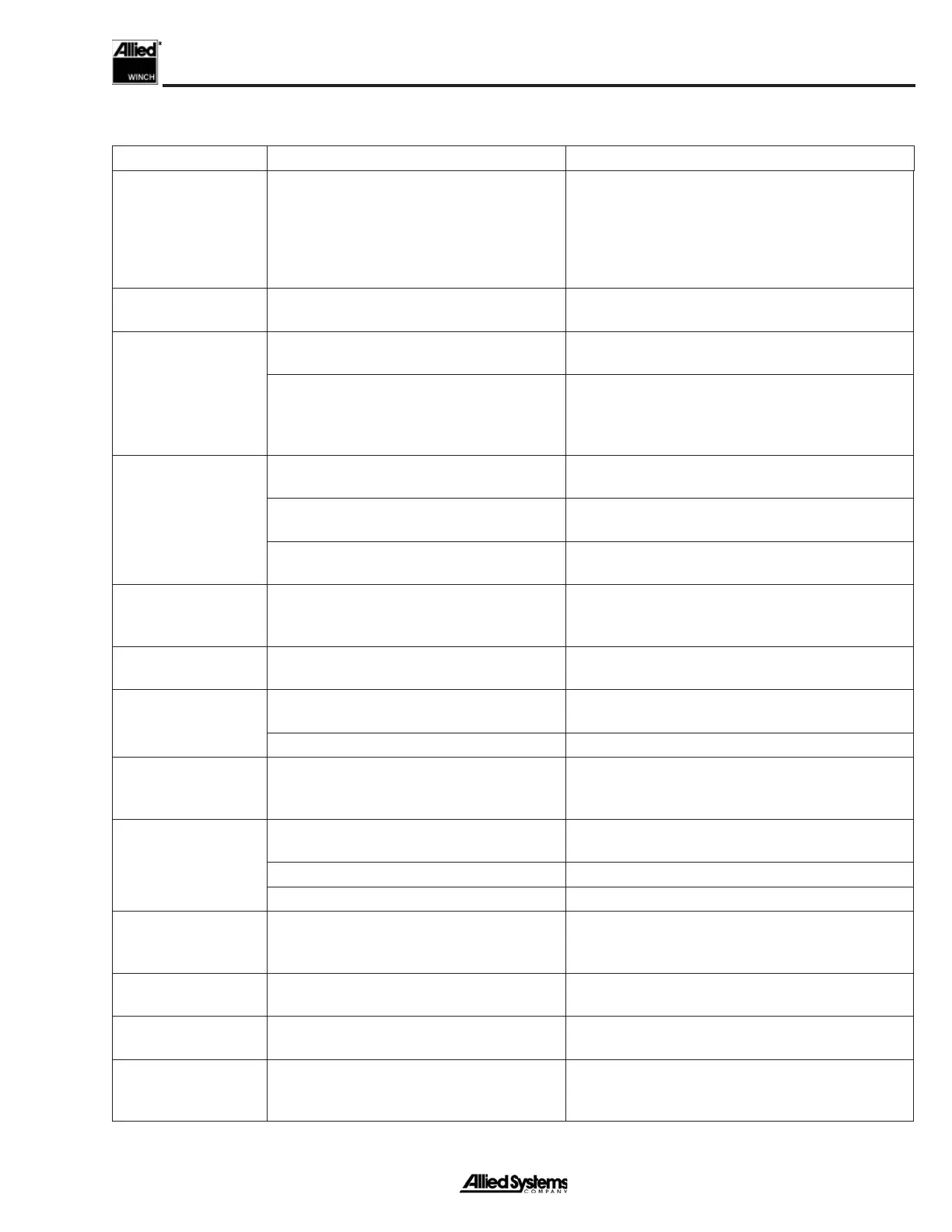

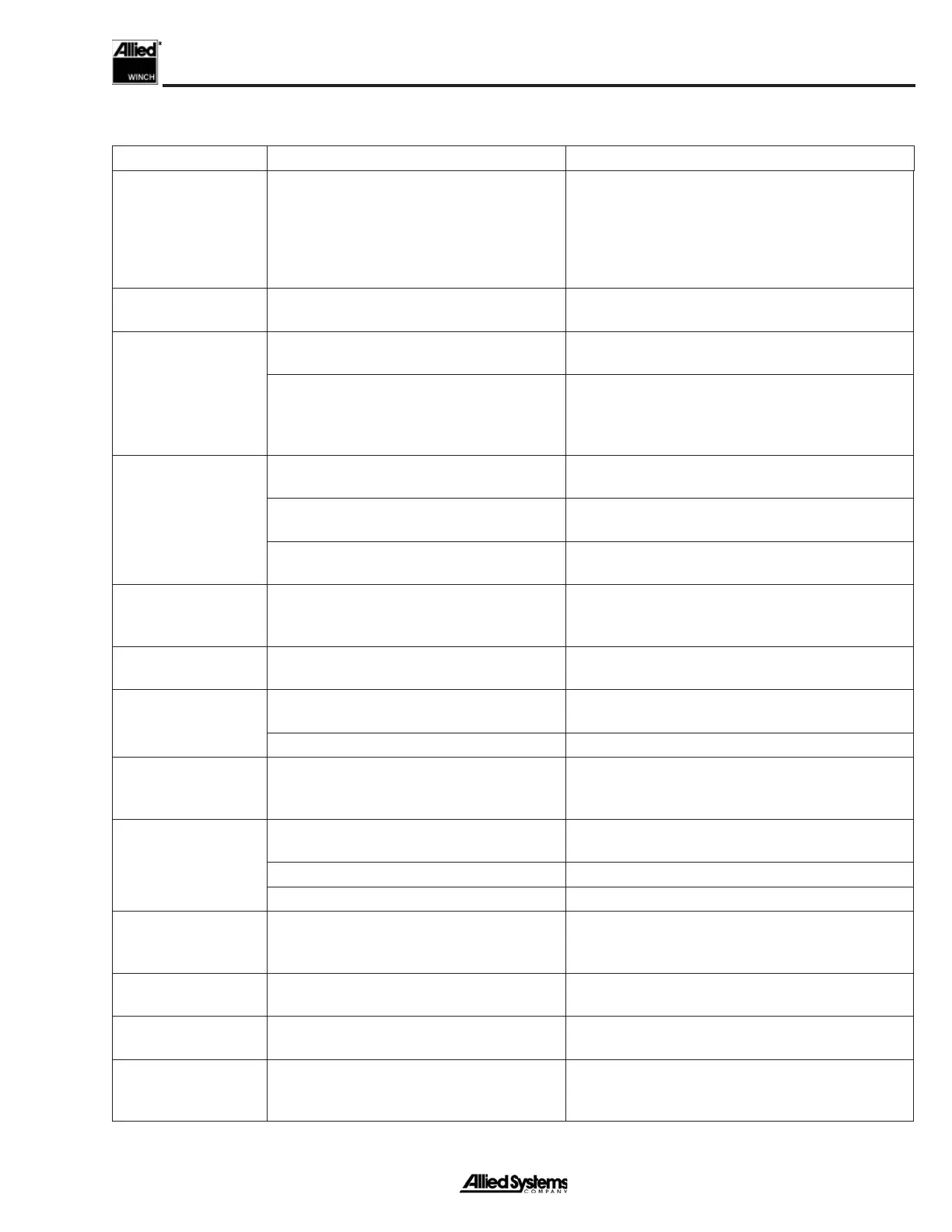

Figure 4-8 Visual Inspection (continued)

ITEM INSPECTION REQUIREMENTS CORRECTIVE ACTION

Winch Motor (Cont.) Inspect stator for wear or damage. Normal wear results in polishing of cam form

which does not impair motor performance. No-

ticeable wear may be apparent along the corner

of one side of the vane slot. This does not require

replacement of the stator, but may slightly affect

volumetric effi ciency.

Direction Control

Manifold

Check that all passages and cartridge

valves are free of contaminants.

Clean or replace cartridge valves. Clean all hy-

draulic passages.

Logic Control

Manifold

Check that all passages and cartridge

valves are free of contaminants.

Clean or replace cartridge valves. Clean all hy-

draulic passages.

Check torque on solenoid coils. Do not

over-tighten.

Check that solenoid spool moves freely. Replace

cartridge if stiction is present. Torque for solenoid

cartridge is 20 ft-lbs. Torque for coil retaining nut

is 5 ft-lbs.

BRAKE-OFF Mani-

fold

Check that all passages and cartridge valves

are free of contaminants.

Clean or replace cartridge valve. Clean all hydraulic

passages.

Check that 2-speed switch illuminates

when BRAKE-OFF activated.

If no fault in 2-speed switch check or replace wire

harness.

Check that 2-speed switch illuminates when

activated and turns off when deactivated.

Check harness connections or replace relay and

pressure switches.

FREESPOOL Shifter Check oil level in winch is not over full. This

is an indication that the FREESPOOL hose

or piston seals are leaking.

Tighten or replace FREESPOOL shifter hose.

Replace piston seals.

FREESPOOL Dental

Clutch

Check for broken or worn teeth. Replace dental clutch if teeth are broken or se-

verely worn.

Intermediate Shaft Check for deep scratches or scoring on

bearing surfaces at each end of shaft.

Dress surface or replace shaft if severely worn.

Check for broken or severely worn splines. Replace if splines are broken or severely worn.

Intermediate Gears Inspect both gears for broken or severely

worn teeth. Pay particular attention to lead-

ing edges of straight-cut gear teeth.

Replace gears if teeth are broken or severely worn.

Drum Shaft Check for deep scratches or scoring on

bearing surfaces.

Dress surface or replace shaft if severely worn.

Check O-ring groove and seal surface. Dress groove or replace shaft if severely worn.

Check for crossthread or damaged threads. Dress threads with thread chaser.

Drum Gear Check for broken or severely worn gear

teeth. Pay particular attention to leading

edges of straight-cut gear teeth.

Replace gear if teeth are broken or severely worn.

Drum Inspect quad-ring groove for burrs, scoring

and rust.

Replace drum or rebuild drum groove if a new quad-

ring will not seat properly.

Drum Adapter Carefully inspect double seal contact sur-

face for deep scratches, burrs and rust.

Replace if damaged.

Winch Frame Check area around drum and drum adapter

for damage if cable has slipped between

cable guard and winch frame.

Consult the factory.

Loading...

Loading...