SYSTEM OPERATION

21

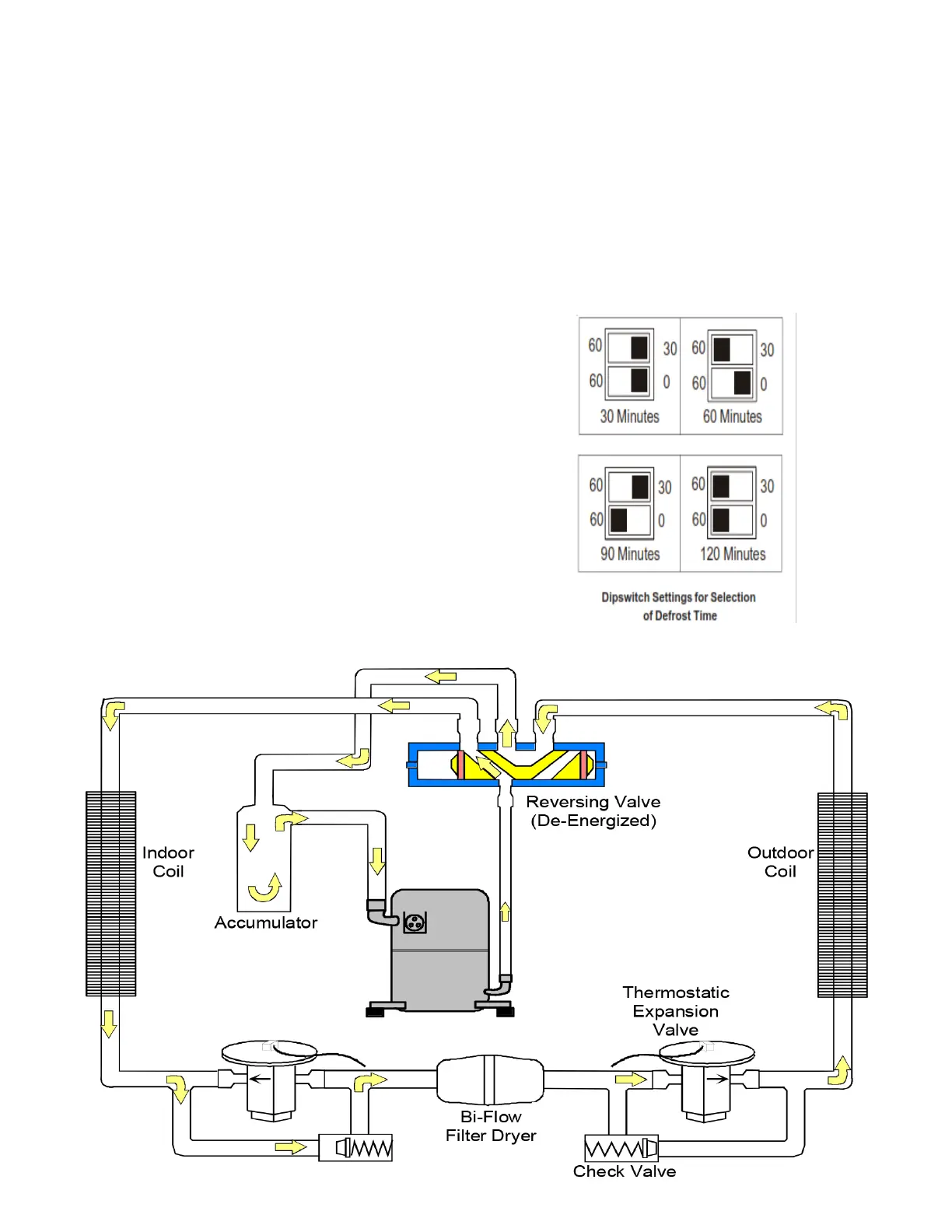

The heating portion of the refrigeration cycle is similar

to the cooling cycle. By energizing the reversing valve

solenoid coil, the ow of the refrigerant is reversed. The

indoor coil now becomes the condenser coil, and the

outdoor coil becomes the evaporator coil.

The check valve at the indoor coil will open by the ow

of refrigerant letting the now condensed liquid refrigerant

bypass the indoor expansion device. The check valve at

the outdoor coil will be forced closed by the refrigerant ow,

thereby utilizing the outdoor expansion device.

The defrosting of the outdoor coil is jointly controlled by the

UC PCB and the outdoor coil temperature (OCT) sensor.

The OCT sensor is clamped to a feeder tube entering the

outdoor coil. Defrost timing periods of 30, 60, 90 or 120

minutes may be selected via the dipswitch settings on

the UC PCB. During operation, if the coil temperature is

low enough (approximately 31° F), the microprocessor

will accumulate the compressor run time. When the total

compressor run time reaches 30, 60, 90 or 120 minutes,

and there is a call for heat, the PCB will initiate a defrost

cycle.

When the microprocessor detects the coil temperature to

be high enough (approximately 75 0F), or 10 minutes of

maximum defrost cycle time has elapsed, whichever occurs

rst, the defrost cycle is terminated and the timing period is

reset. The eld service personnel can also advance a heat

pump to the defrost cycle by simultaneously pressing the

“TEST” button and the “RECALL” button on the UC board.

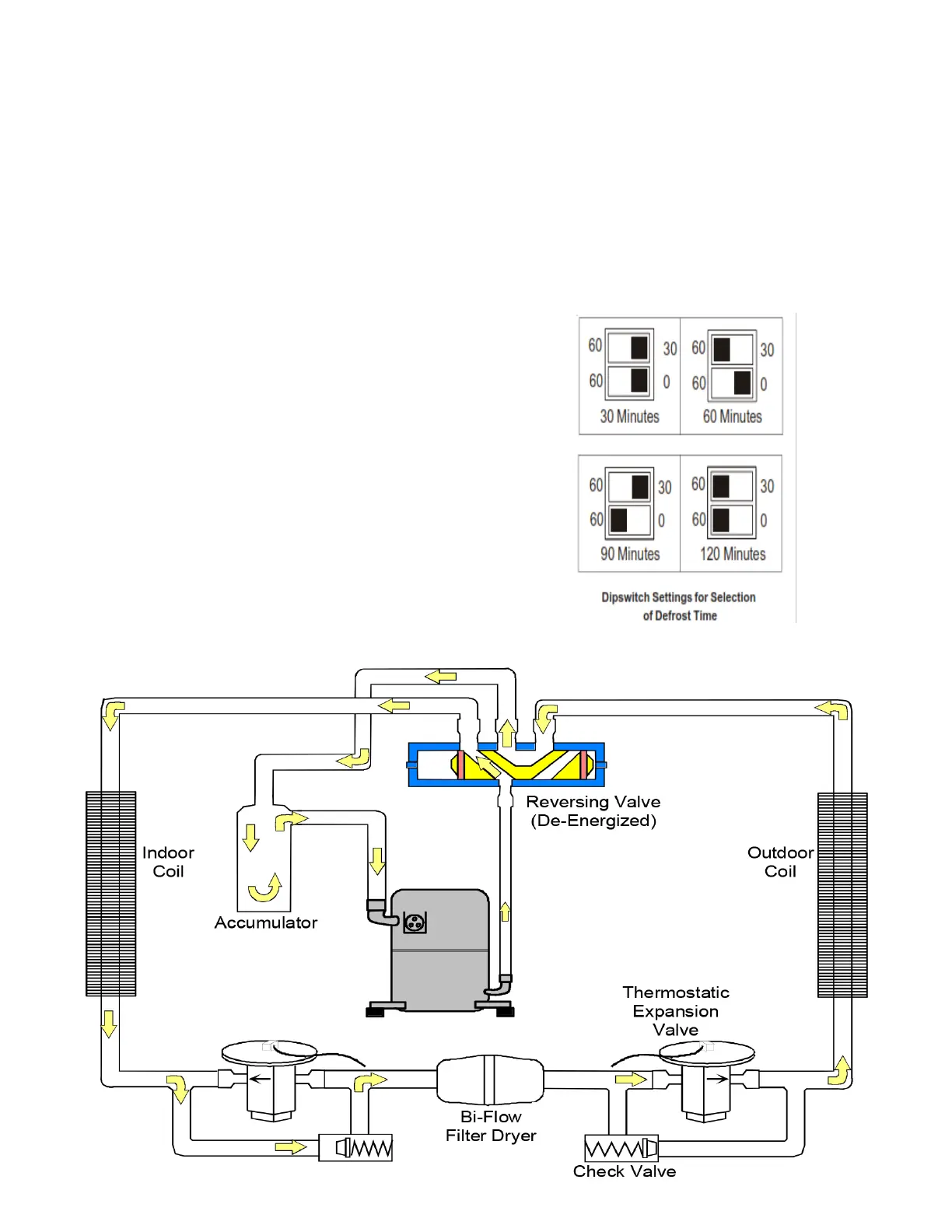

Use the dipswitches to select defrost time interval (30, 60,

90 or 120 minutes) See chart below

Loading...

Loading...