SERVICING

42

Occasionally the reversing valve may stick in the heating or

cooling position or in the mid-position.

When stuck in the mid-position, part of the discharge gas

from the compressor is directed back to the suction side,

resulting in excessively high suction pressure. An increase

in the suction line temperature through the reversing valve

can also be measured. Check operation of the valve

by starting the system and switching the operation from

COOLING to HEATING cycle.

If the valve fails to change its position, test the voltage

(24V) at the valve coil terminals, while the system is on the

COOLING cycle.

All heat pumps and communicating heat pumps wired

in legacy - If no voltage is registered at the coil terminals,

check the operation of the thermostat and the continuity

of the connecting wiring from the “O” terminal of the

thermostat to the unit.

Communicating heat pumps only - Check voltage

(24VAC) at the non-insulated terminal E22 on the UC

control board (RVS on silkscreen) and “C” terminal on the

7-pin or 4-pin connector on the UC control

If voltage is registered at the coil, tap the valve body lightly

while switching the system from HEATING to COOLING,

etc. If this fails to cause the valve to switch positions,

remove the coil connector cap and test the continuity of

the reversing valve solenoid coil. If the coil does not test

continuous - replace it.

If the coil test continuous and 24 volts is present at the coil

terminals, the valve is inoperative - replace it.

Legacy Models:

Communicating Units:

To check the defrost control for proper sequencing,

proceed as follows: With power ON; unit not running.

1. Set thermostat to call for heating.

2. Press and buttons simultaneously for

approximately 3 seconds, then release them. System

should go into defrost immediately.

3. Using VOM check for voltage across terminals “C & O”.

Meter should read 24 volts (skip this step if system a

fully communicating system)

4. Visually inspect to see that the frost is gradually melting

on the coil and the compressor is running.

5. Using VOM check for voltage across “W2 & C” terminals

on the board. You should read 24 volts.

6. If not as above, replace control board.

7. Set thermostat to o position and disconnect power

before removing any jumpers or wires.

The ASXC and DSXC air conditioner

models are factory equipped with an outdoor air

temperature (OAT) sensor.

The ASZC and DSZC heat pump models

are equipped with both an outdoor air temperature (OAT)

sensor and an outdoor coil temperature (OCT) sensor. The

OAT provides the balance point temperature in heat pump

systems (air handler w/electric heat + heat pump) and dual

fuel systems. The OCT sensor provides the outdoor coil

temperature and is used in determining defrost cycles.

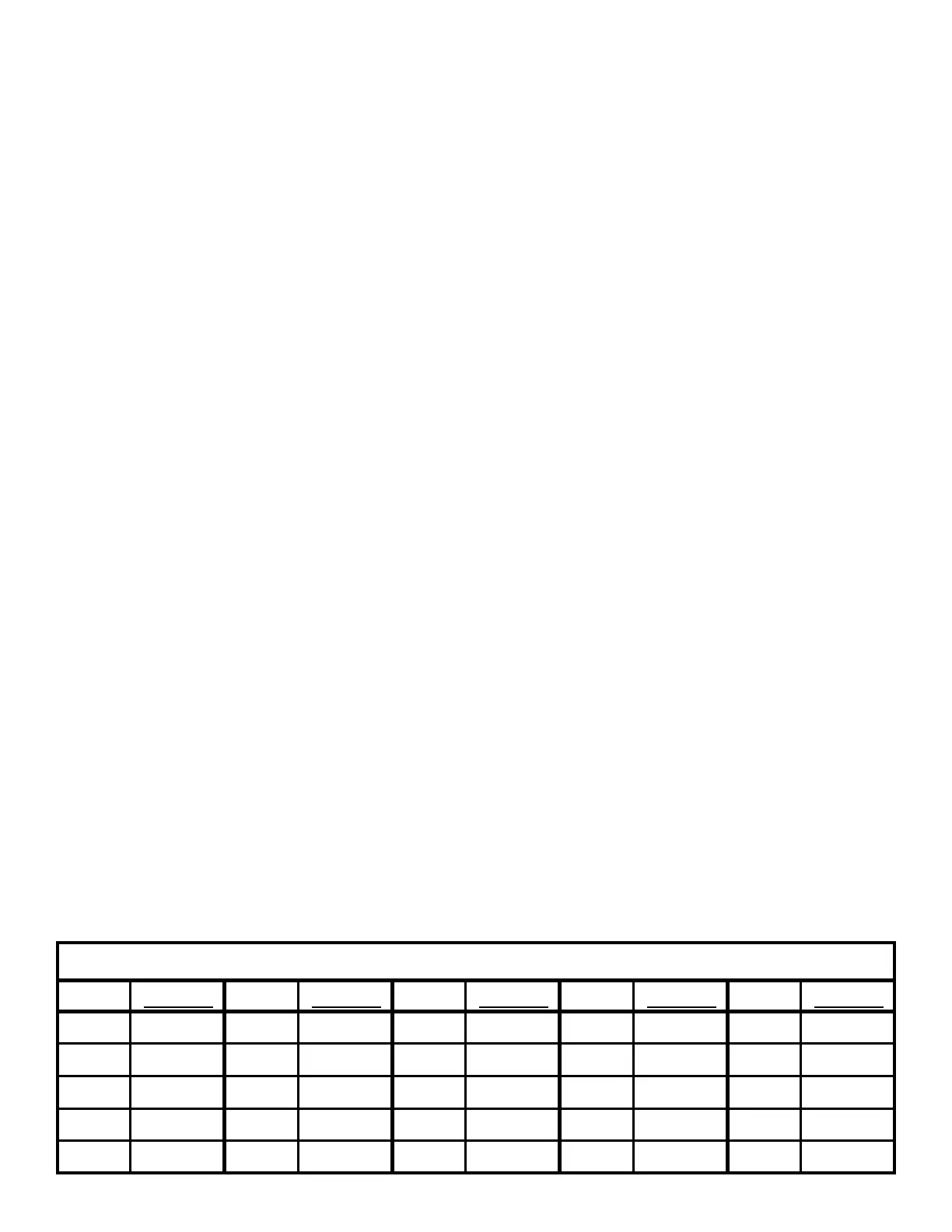

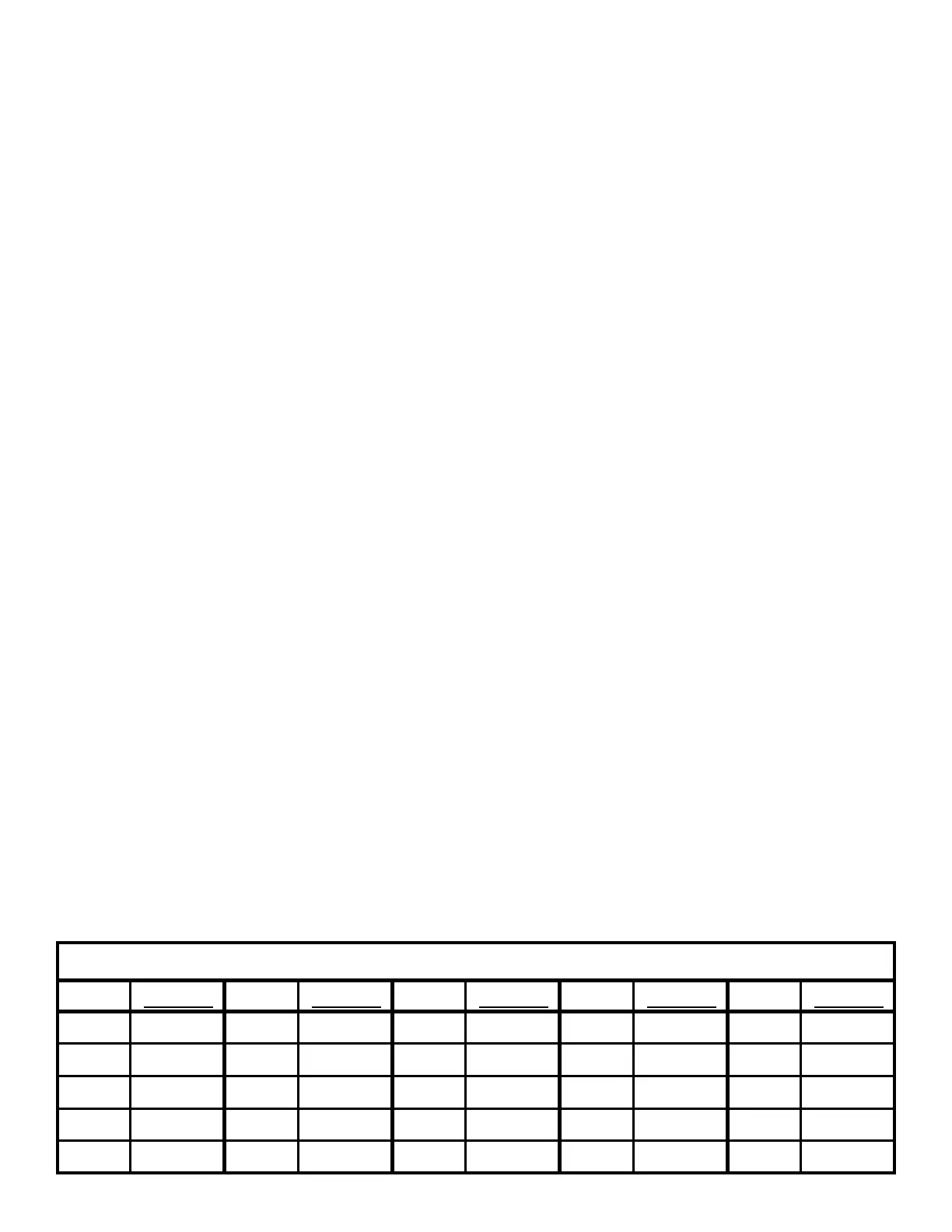

-40 336,000 5 72,940 50 19,903 95 6,530 140 2,488

-31 242,700 14 55,319 59 15,714 104 5,327 149 2,083

-22 177,000 23 42,324 68 12,493 113 4,370 158 1,752

-13 130,400 32 32,654 77 10,000 122 3,603 167 1,480

-4 97,060 41 25,396 86 8,056 134 2,986 176 1,255

Loading...

Loading...