UG-1308 EVAL-ADuCM355QSPZ Evaluation Board

Rev. A | Page 14 of 24

Current through SE0.

Voltage o

n SE0.

Voltage on RE0

.

Curren

t through SE0 measured a second

time.

T

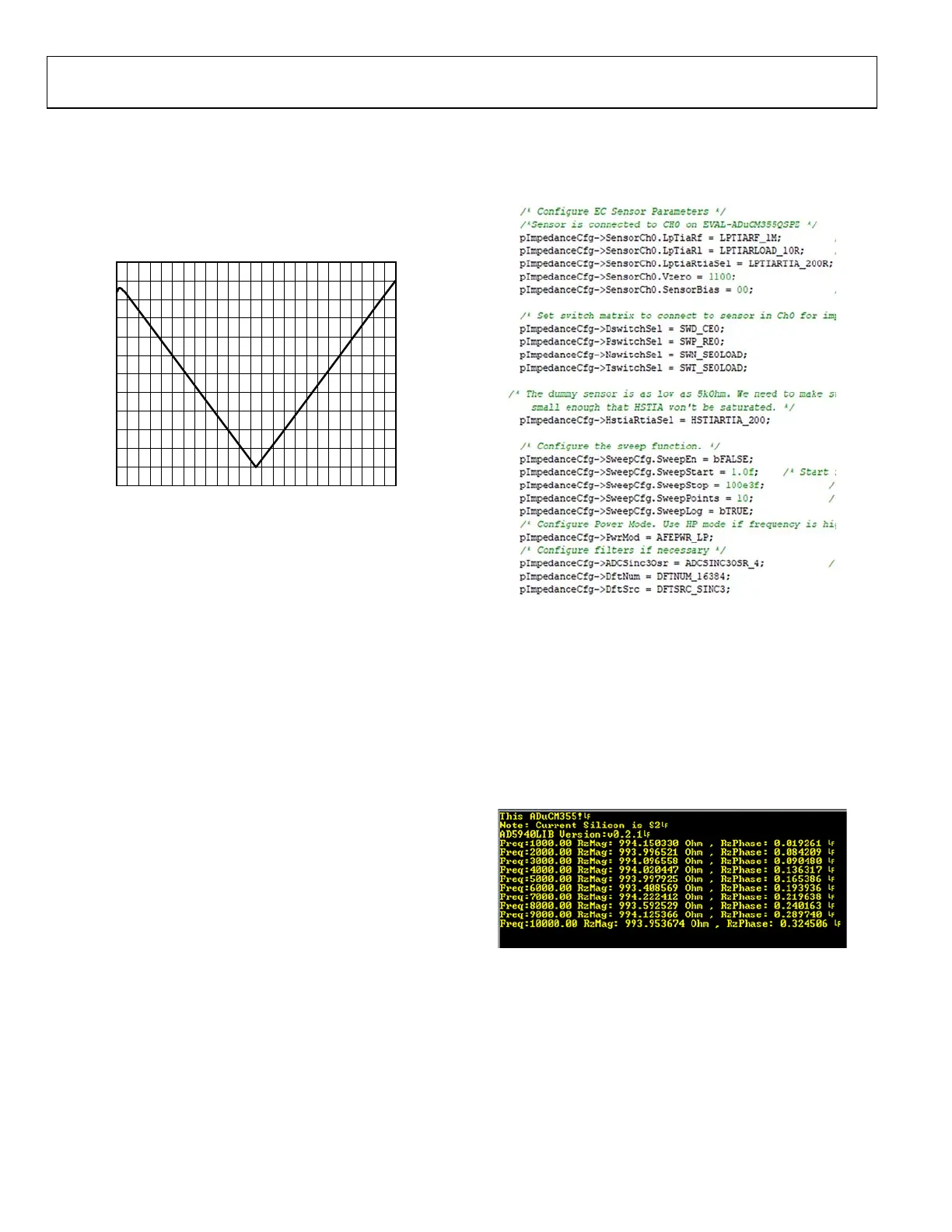

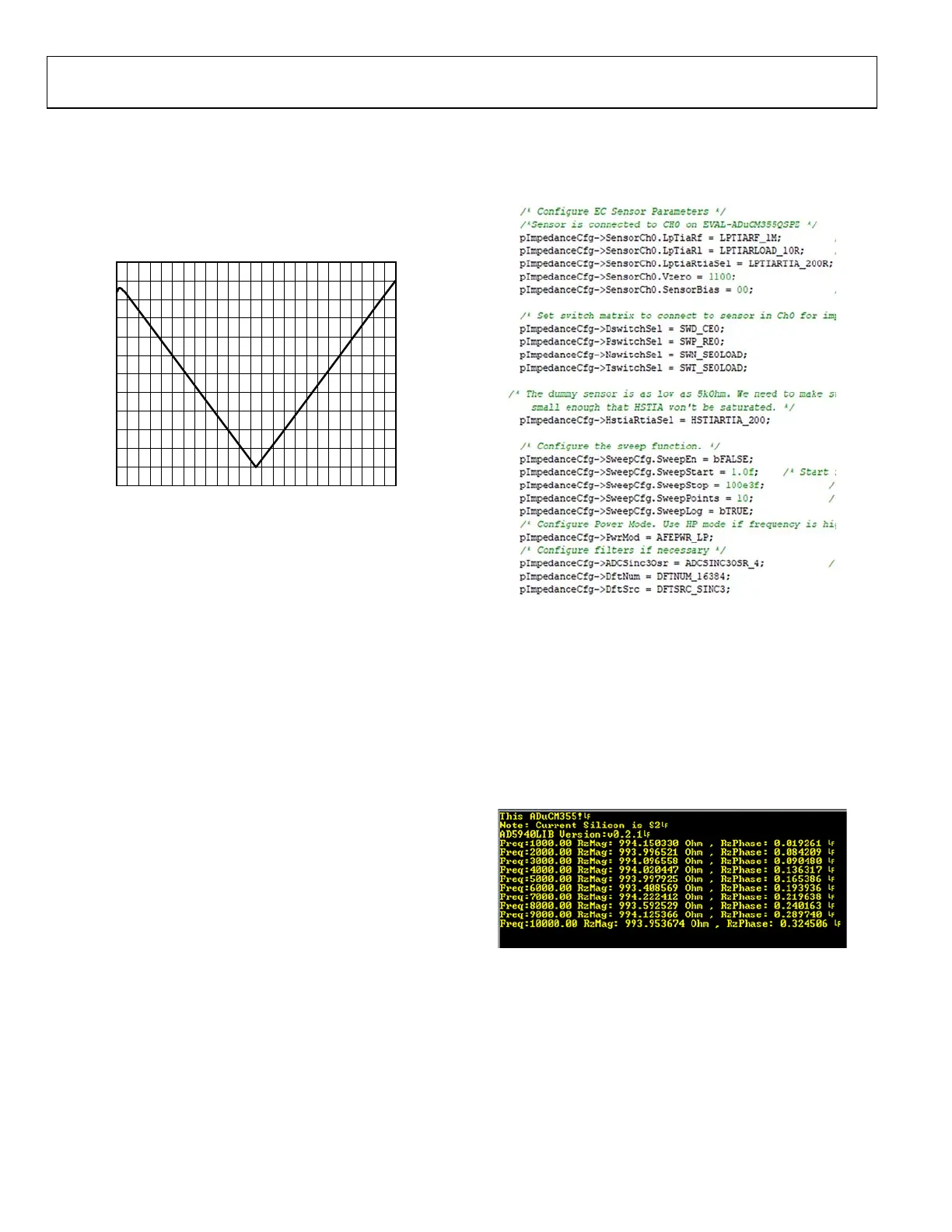

o plot the current response of the test, open the saved .csv file in

Microsoft® Excel. Figure 23 shows the plotted response current.

–600

–500

–400

–300

–200

–100

100

0

200

300

500

400

600

1

17

33

49

65

81

97

113

129

145

161

177

305

193

209

225

241

257

273

289

321

337

353

369

385

CURRENT (µA)

INDEX

16887-017

Fi

gure 23. Example SE0 Channel Current Measurement

EIS EXAMPLE

EIS is a common electrochemical measurement in which an ac

excitation signal is applied to an electrochemical cell. The response

current is measured, and the impedance is calculated.

On the ADuCM355, the EIS measurement is a three-step process.

The response current in each step is measured using a high

speed transimpedance amplifier (TIA).

The EIS measurement process is as follows:

1. A signal is applied across R

CAL

.

2. A sig

nal is applied across R

LOAD

.

3. A sig

nal is applied across Z

SENSOR

+ R

LOAD

.

In each ste

p of the measurement processes, the measured current is

input to the discrete Fourier transform (DFT) hardware accelerator

that calculates the complex number of the current measurement

and provides the real and imaginary parts. R

CAL

is a precision

resistor connected to the ADuCM355 RCAL0 and RCAL1 pins,

R

LOAD

is the internal load resistor on the SE0 path, and Z

SENSOR

is

the impedance under test.

Use the following equation to calculate the actual impedance:

Z

SENSOR

= (Z

SENSOR

+ R

LOAD

)− Z

RLOAD

where:

Z

SENSOR

+ R

LOAD

is the impedance of R

SENSOR

and R

LOAD

measured

together as a single impedance.

Z

RLOAD

is the impedance of R

LOAD

.

Open the M355_ECSns_EIS example project in the preferred

IDE. For the purpose of this initial test, a dummy electrochemical

cell is used. Connect three 1 kΩ resistors in a star network, and

connect the star network to the CE0, RE0, and SE0 pins on P5

of the EVAL-ADuCM355QSPZ (see Figure 22).

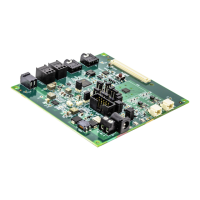

In the AD5940Main.c file, there are several configurable

parameters that are shown in Figure 24. To couple the ac excitation

signal on top of a dc bias, set the SensorCH0.SensorBias parameter.

To apply a frequency sweep, modify the SweepCfg parameters.

16887-225

Figure 24. EIS Parameters

To run the impedance measurement, take the following steps:

1.

Launch the debugger in the IAR Embedded Workbench.

2. Open a terminal program with a 230,400 bps baud rate.

3. Execute the code.

4. A prompt to press the S2 switch is sent over the UART and

displays in the terminal. Press S2 to begin the impedance test.

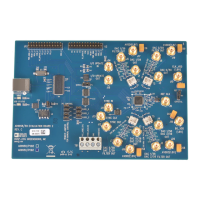

5. When the impedance measurement completes, the results

are sent to the UART (see Figure 25). Save the results in a

Microsoft Excel file for further analysis, if necessary.

16887-019

Fi

gure 25. Impedance Results

CHRONOAMPEROMETRY EXAMPLE

Chronoamperometry is an electrochemical technique in which

the voltage applied to an electrochemical cell is stepped. The

response current on the sense electrode is measured. Figure 26

and Figure 27 show typical chronoamperometric measurement

and sensor responses.

Loading...

Loading...