UG-1308 EVAL-ADuCM355QSPZ Evaluation Board

Rev. A | Page 10 of 24

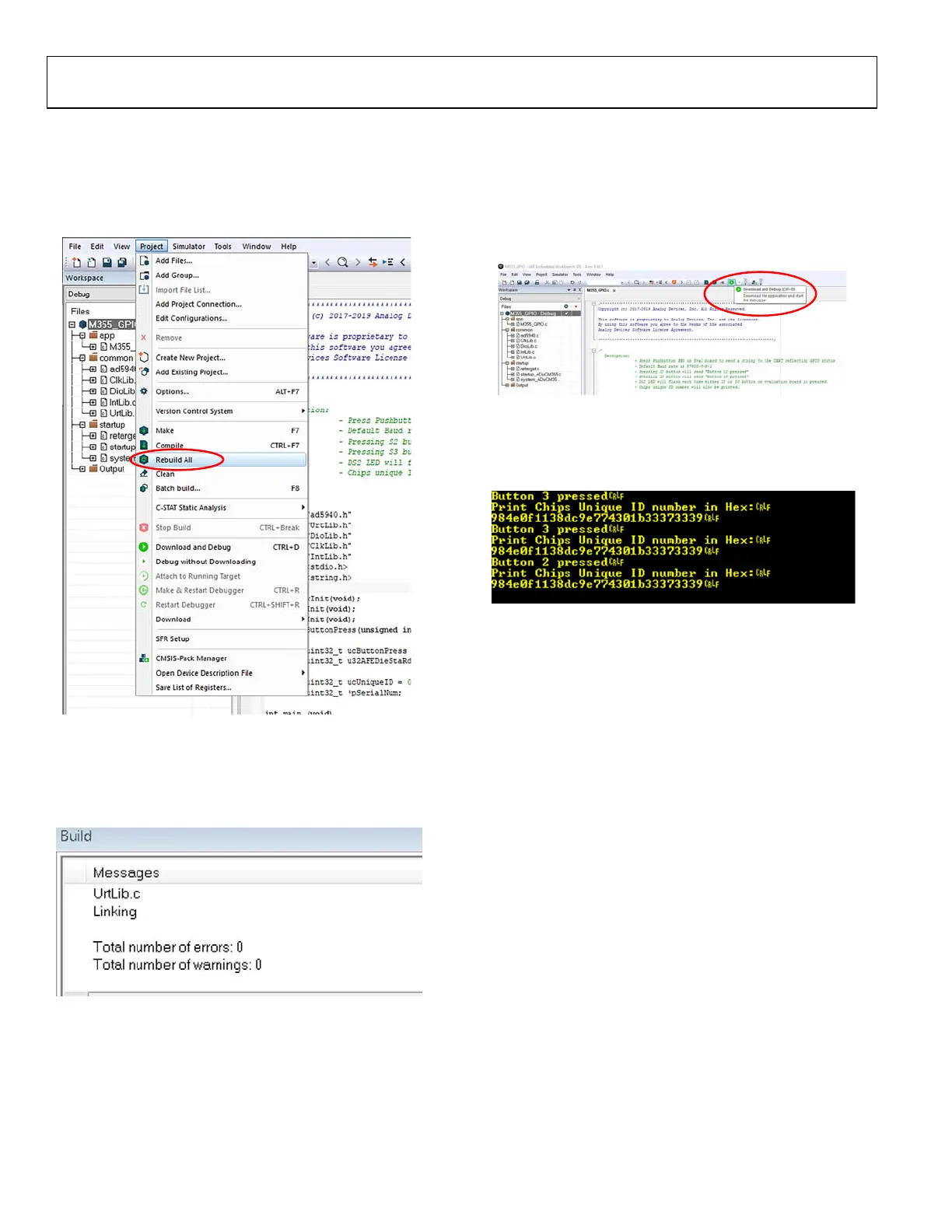

Compiling and Running Firmware

To compile and run the ADuCM355 firmware, take the

following steps:

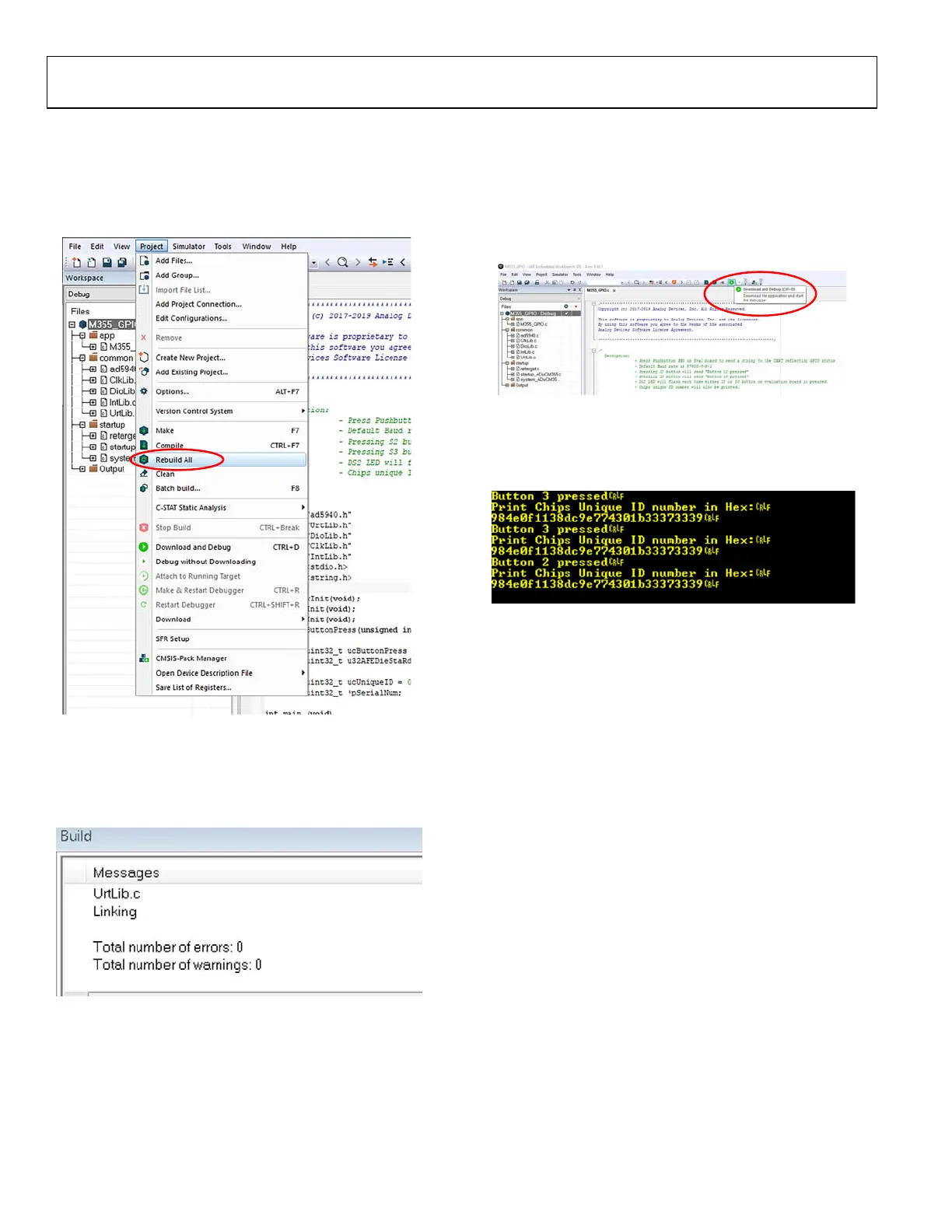

1. In the IAR Embedded Workbench window, navigate to

Project > Rebuild All (see Figure 10).

16887-010

Figure 10. Project > Rebuild All

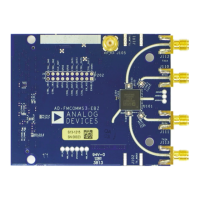

2. Click Rebuild All. The IDE begins building the executable

from the source files, which may take a couple of seconds.

The message shown in Figure 11 appears in the Build window

when the build is complete.

16887-013

Figure 11. Build Output Window

3. To run the firmware on the ADuCM355, ensure that the

EVAL-ADuCM355QSPZ is powered on and the J-Link

debugger is connected to P3 on the EVAL-ADuCM355QSPZ,

then click Download and Debug to load the firmware to

the ADuCM355 and launch the debugger (see Figure 12).

Launching and downloading the debugger can take a few

seconds or more.

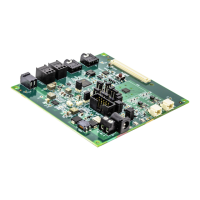

16887-011

Figure 12. Launching the Debugger

4. Open a terminal program such as RealTerm to view the

UART data from the ADuCM355 (see Figure 13). The

baud rate is 230,400 bps.

16887-113

Figure 13. UART Data in RealTerm

5. Figure 14 shows the debug interface. Click the blue arrow

(shown in the red circle) to begin code execution. The UART

prompts the user to press either the S2 or S3 button. The

DS2 LED toggles on and off with each button press.

Loading...

Loading...