39

13-4 Autoclave

After removal, the pipette lower part can be sterilized in an autoclave.

*Only as for the MPA series

Autoclave settings for lower part: Run at 121℃ at 2 ATMs for 20 minutes

・Be sure to allow the lower part to completely dry before reassembling the pipette.

・Please refrain from using sterilization processes other than autoclave as they can

damage the pipette.

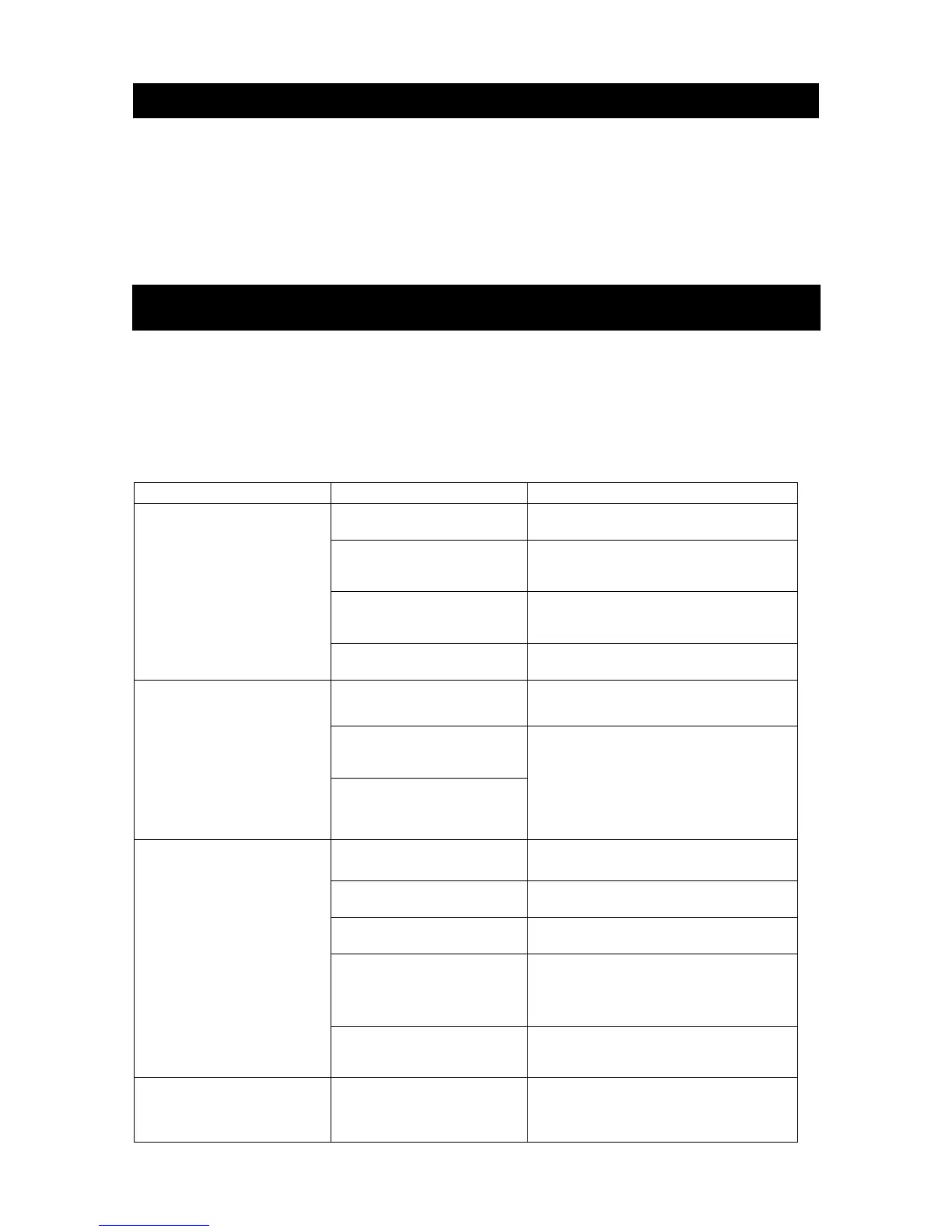

14. TROUBLE SHOOTING

Due to repeatedly aspirating and dispensing various liquids the micropipette easily

succumbs to damage and contamination. In the event of device failure consult the

following table. Request repair if that still doesn’t solve the problem. (Refer to “15.

WHEN REQUESTING REPAIR”)

Problem Reason How to fix

Battery not charged Charge the battery

Battery connector not

properly attached

Remove and reattach the

battery connector

Contamination of

electrodes

Clean electrodes

Device won’t turn on

Battery degradation Replace the battery

Battery charge

insufficient

Charge the battery

Tip holder head

jammed

Device will not aspirate

Piston doesn’t move

Clean or replace the lower part

*When cleaning ensure no

foreign objects enter the

piston section

Use of contaminated

tip

Use a new tip

Tip is loose Attach the tip properly

Piston seal is defective Replace the lower part

Abrasion, denting, or

damage to the tip

holder

Replace the lower part

Leakage from the tip

Use of volatile liquids Refer to “10 PIPETTING FOR

ACCURATE DISPENSING”

Liquid remains in the

tip

Liquid has high

viscosity

Refer to “9-6 Reverse operation”

Loading...

Loading...