A1 38 DTR.APC.APR.ALW.03

(ENG)

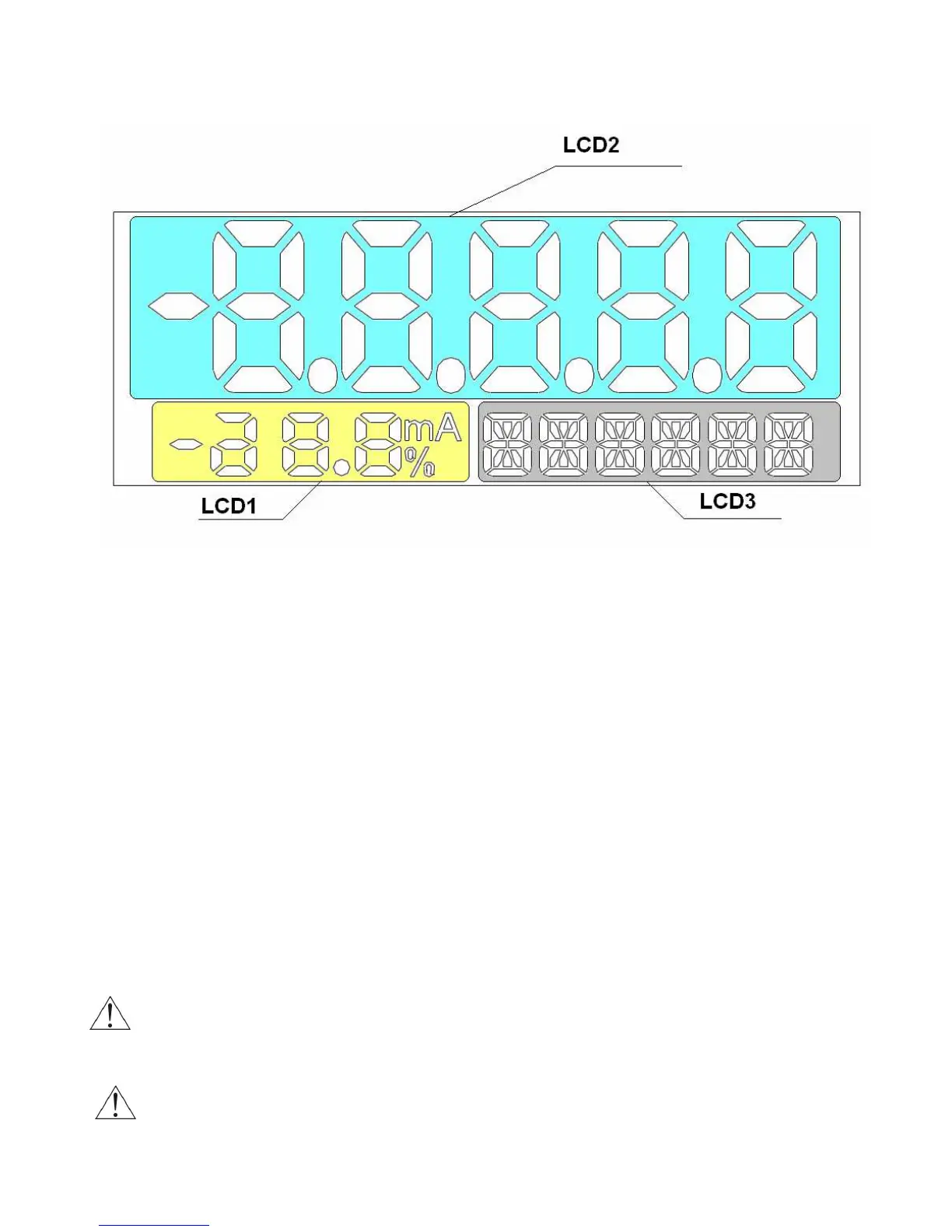

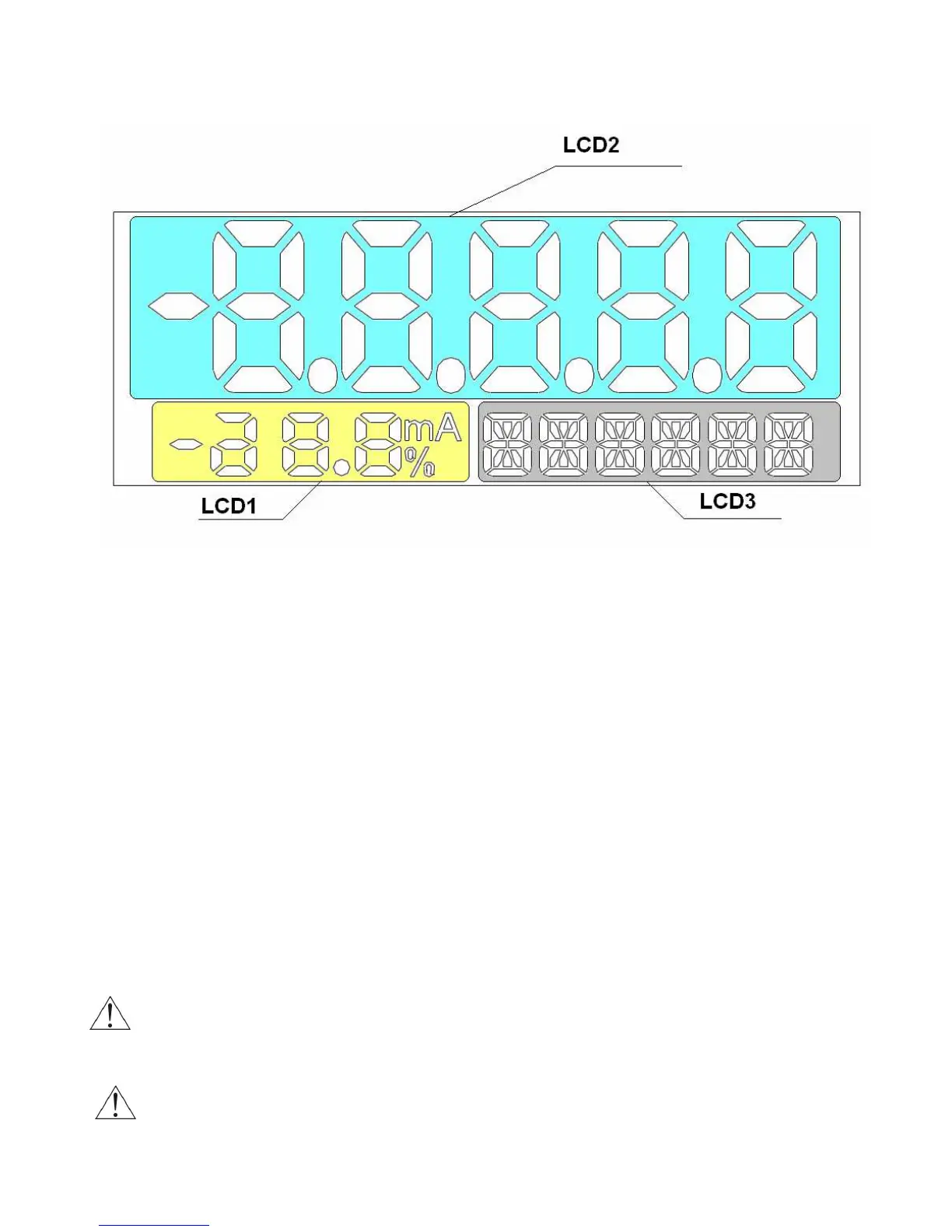

10.2.5.3. Setting up a local LCD display - the display in accordance with EN 12405-1 (MID)

installed since 2011.

There 3 main displays are visible

:

•

LCD1 – the current or guidance percent preset range display. In accordance with display configuration the

current value in 4 -20 mA current loop, or percent guidance preset range is possible to display.

• LCD2 – the measured pressure digital value display; the calibrated pressure value according to user’s

units display; the process variable units, or user’s units, or pressure sensor or CPU temperature; the

MENU announcement and other information or warning announcement display. In the case the digital

pressure value or the calibrated pressure value display, the sign „–„ can be visible before displayed value.

The decimal point position is possible to set in local MENU or remotely. The pressure unit or user’s unit

can be displayed. The transmitter makes possible rescale on the user's individual the pressure value. To

make this is necessary with using communicator or PC software write the corresponding to beginning and

to end values of setting range as well as write the own unit name. After activating user's mode the rescale

value will be visible on display.

• LCD3 – information display. During normal operation is designed for continuous display of the base unit or

the user units. In case of errors in the transmitter's work , it displays an error number. In manual mode, the

local change settings menu displays options of selecting the setting. It also displays errors related to the

implementation of commands in the local menu of the settings change.

• Display backlighting - Local display is equipped in backlight, switching on and switching off with jumper

on electronic board. How to handle display backlight is shown in Figure 4a. Figure 4 shows how to change

the display position by rotation.

Warning!

Exceeding the basic transmitter measuring range over 50% range in the up or down is indicated

by " o V E r " or " u n d E r " in the display LCD2. Such situation is encountered most often when

overloaded a difference pressure transmitter, created when the large static pressure compared

to the pressure range will blockage or a leak in one of the capillaries.

After configuration it is important to protect the transducers using command HART [247].

During work transmitter should be safe prior to entries. This prevents accidental or intentional

changes configurational data. The protection function is accessible in KAP03 communicator,

“Report’s” software, as well as, in applying DD or DMT programs libraries.

Descriptions

Loading...

Loading...