AquaLab 7 VERIFICATION AND CALIBRATION

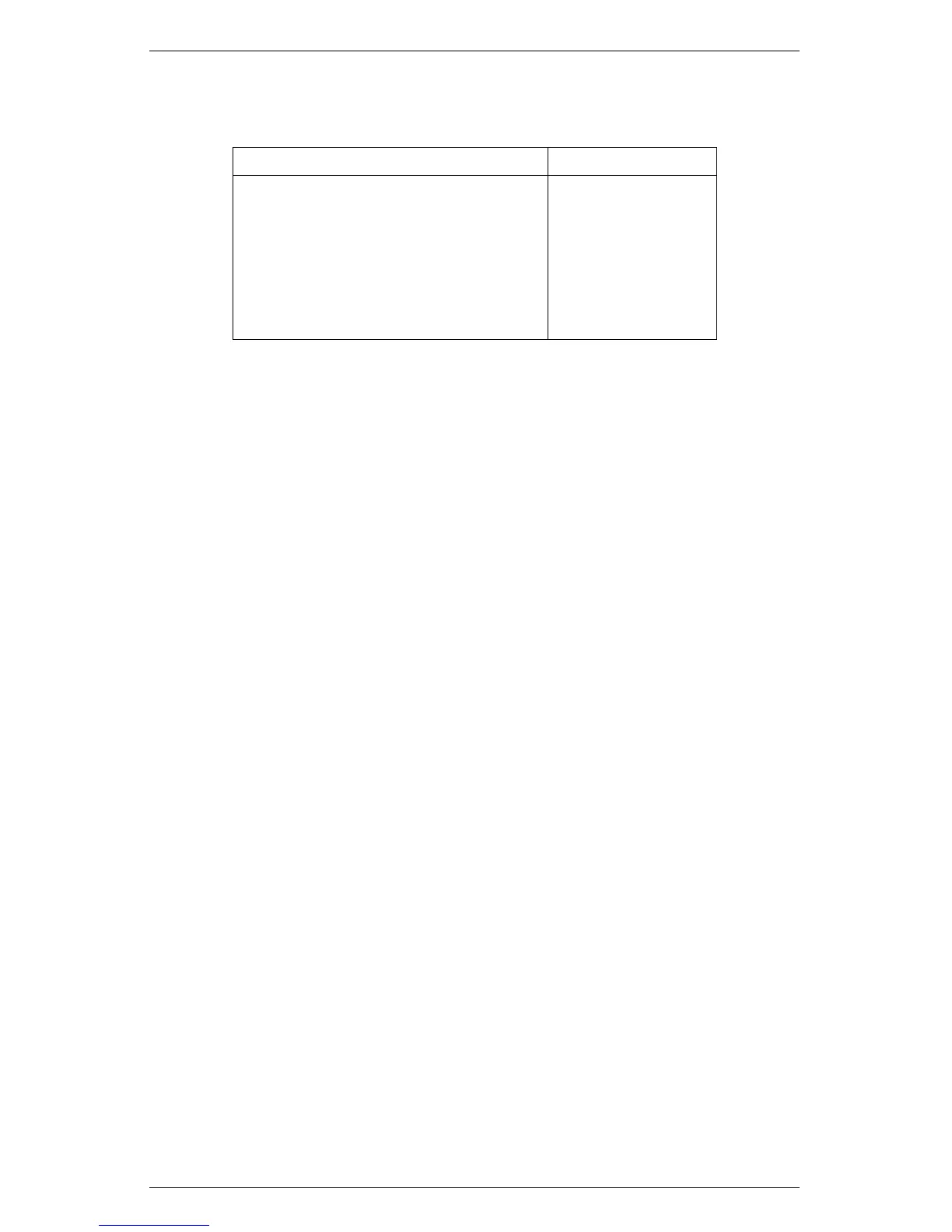

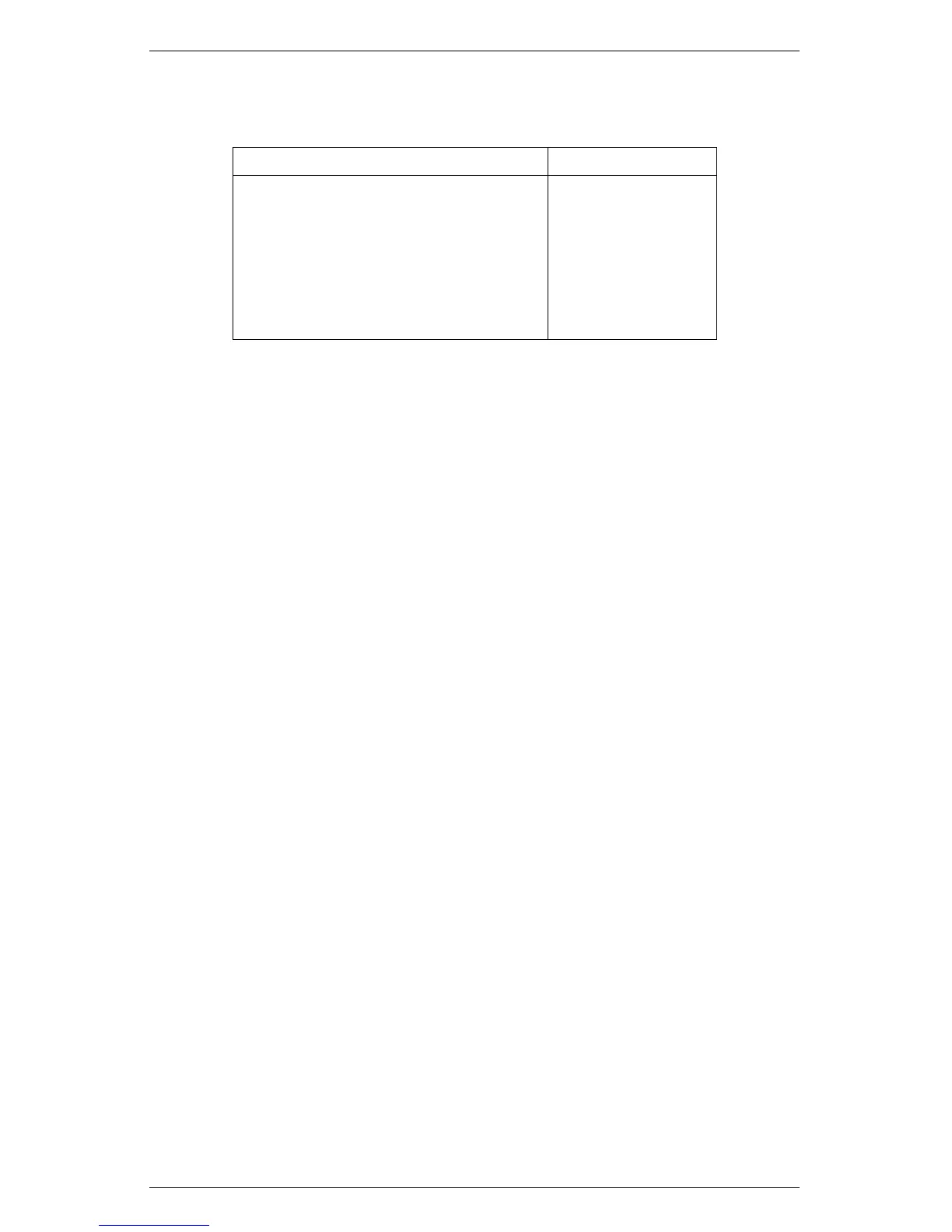

Table 1: Verification Flowchart

Verification Standard @ 25

◦

C Water Activity

13.40 mol/kg LiCl 0.250 ±0.003

8.57 mol/kg LiCl 0.500 ±0.003

6.00 mol/kg NaCl 0.760 ±0.003

2.33 mol/kg NaCl 0.920 ±0.003

0.50 mol/kg KCl 0.984 ±0.003

USP Purified Water 1.000 ±0.003

Note: If you need to obtain a Material Safety Data Sheet (MSDS)

for any of these standards, a printable version is available on our

website at www.decagon.com/msds.

To use a verification standard, remove the twist top and pour the

contents into an AquaLab sample cup. Information about the stan-

dard value and molality can be found printed on the outside of the

plastic vial. If for some reason you cannot obtain Decagon’s ver-

ification standards and need to make a saturated salt solution for

verification, refer to Appendix A.

In TEV models, the capacitance sensor can hold a memory of high

water activity samples such as UPS Purified Water or the 0.984 a

w

standard. If you verify calibration with one of these high water activ-

ity standards, you will need to wait an hour to allow the capacitance

sensor to dry before testing samples of lower water activity or the

results may be slightly high.

7.2 Verification of Calibration

When to Verify for Linear Offset

Linear offset should be checked against two known verification stan-

dards daily, either once per shift or before each use. Linear offset

should never be verified solely against steam distilled water, since

it does not give an accurate representation of the linear offset. For

batch processing, the instrument should be checked regularly against

a known standard of similar water activity. It is also a good idea to

35

Loading...

Loading...