25

(4) Welding

If you should cut or weld the refrigerant system pipes in the process of maintaining, please follow the steps as below:

a. Shut down the unit and cut power supply

b. Eliminate the refrigerant

c. Vacuuming

d. Clean it with N

2

gas

e. Cutting or welding

f. Carry back to the service spot for welding

The refrigerant should be recycled into the specialized storage tank.

Make sure that there isn’t any naked flame near the outlet of the vacuum pump and it’s well-ventilated.

(5) Filling the refrigerant

Use the refrigerant filling appliances specialized for R32. Make sure that different kinds of refrigerant won’t contaminate

with each other.

The refrigerant tank should be kept upright at the time of filling refrigerant.

Stick the label on the system after filling is finished (or haven’t finished).

Don’t overfilling.

After filling is finished, please do the leakage detection before test running; another time of leak detection should be

done when it’s removed.

(6) Safety instructions for transportation and storage

Please use the flammable gas detector to check before unload and open the container.

No fire source and smoking.

Do comply with the local rules and laws.

Installation of Hydraulic Unit

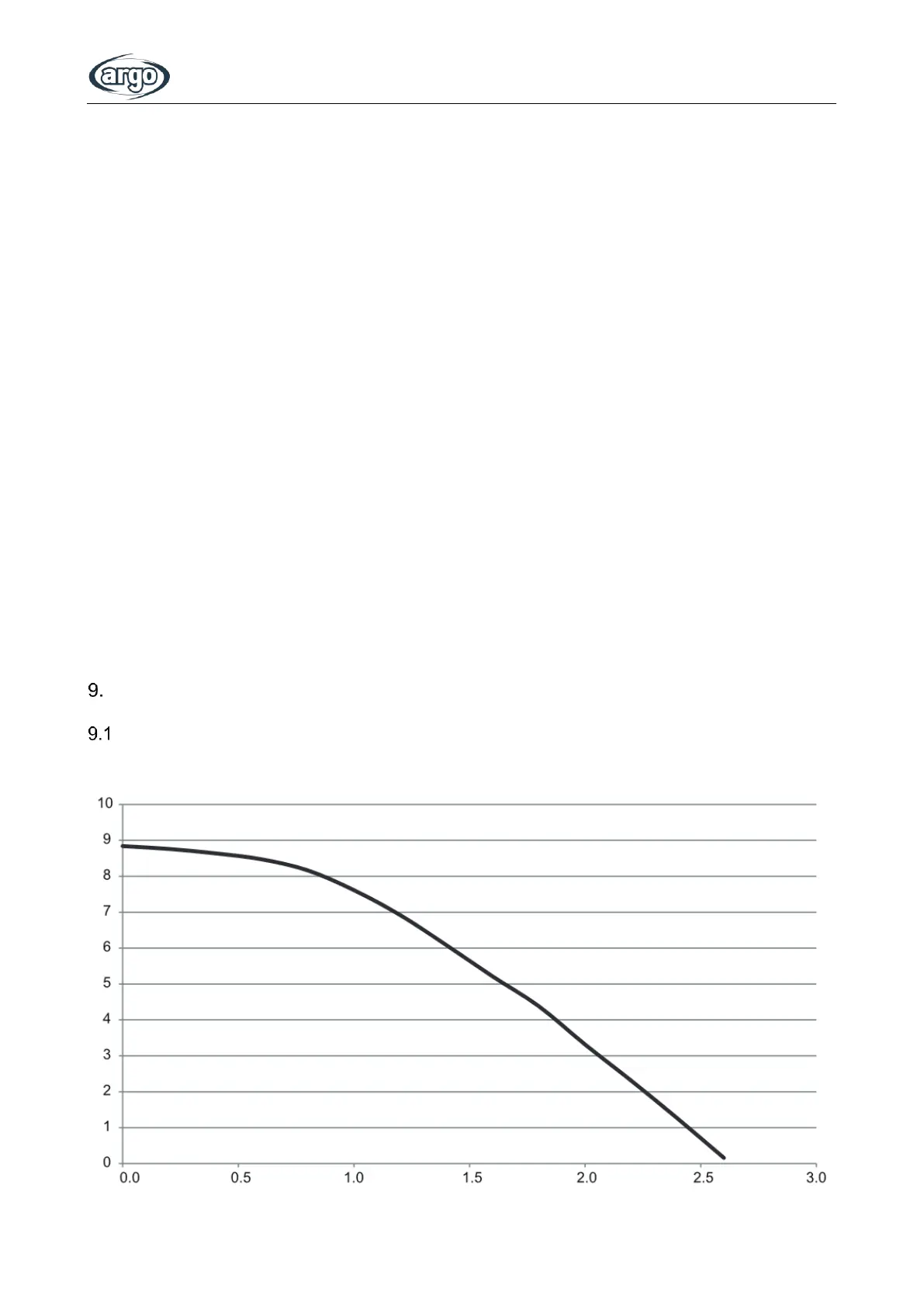

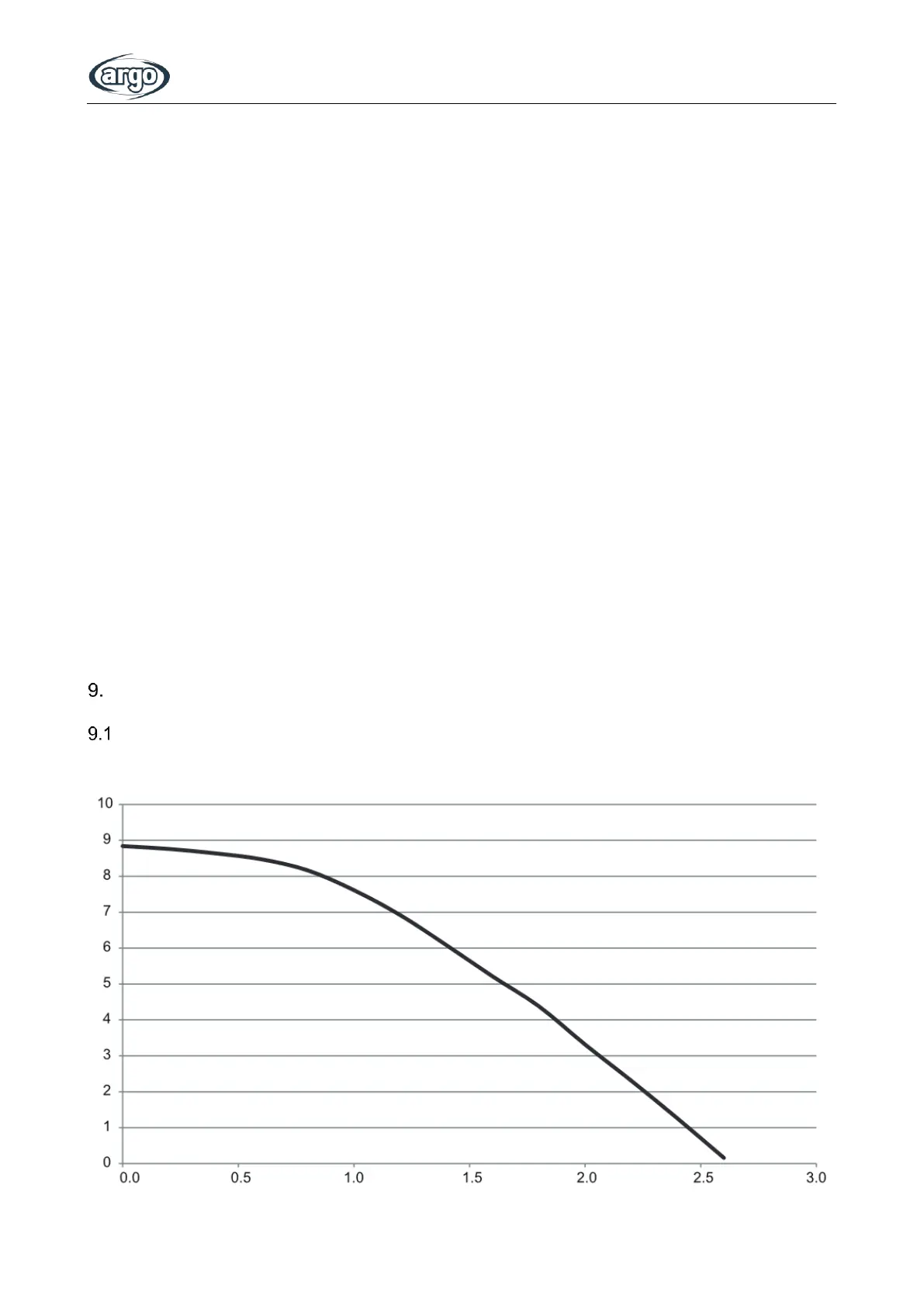

Available external static pressure of outlet

AG4HP061PH

Loading...

Loading...