Initial start-up

31 / EN

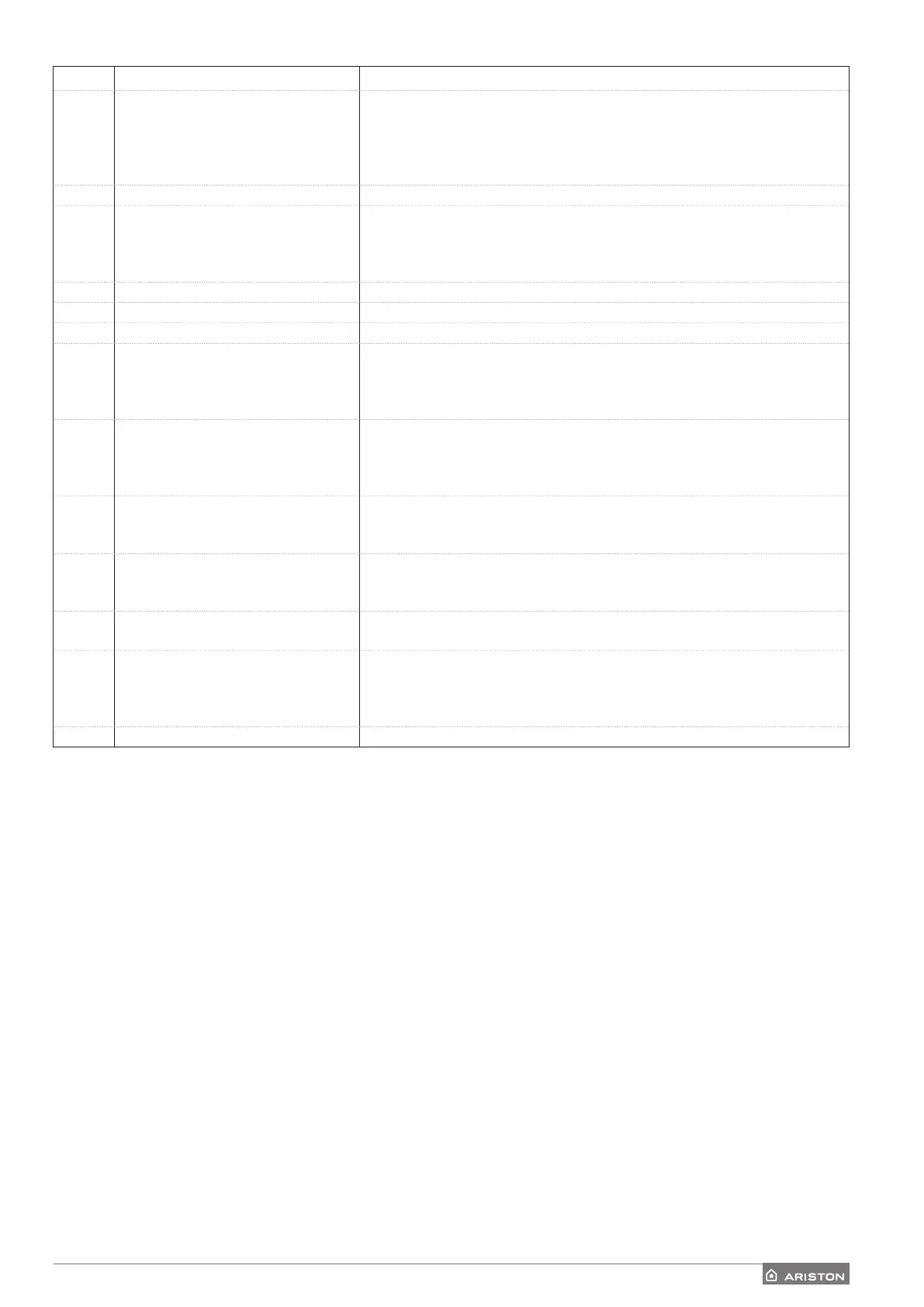

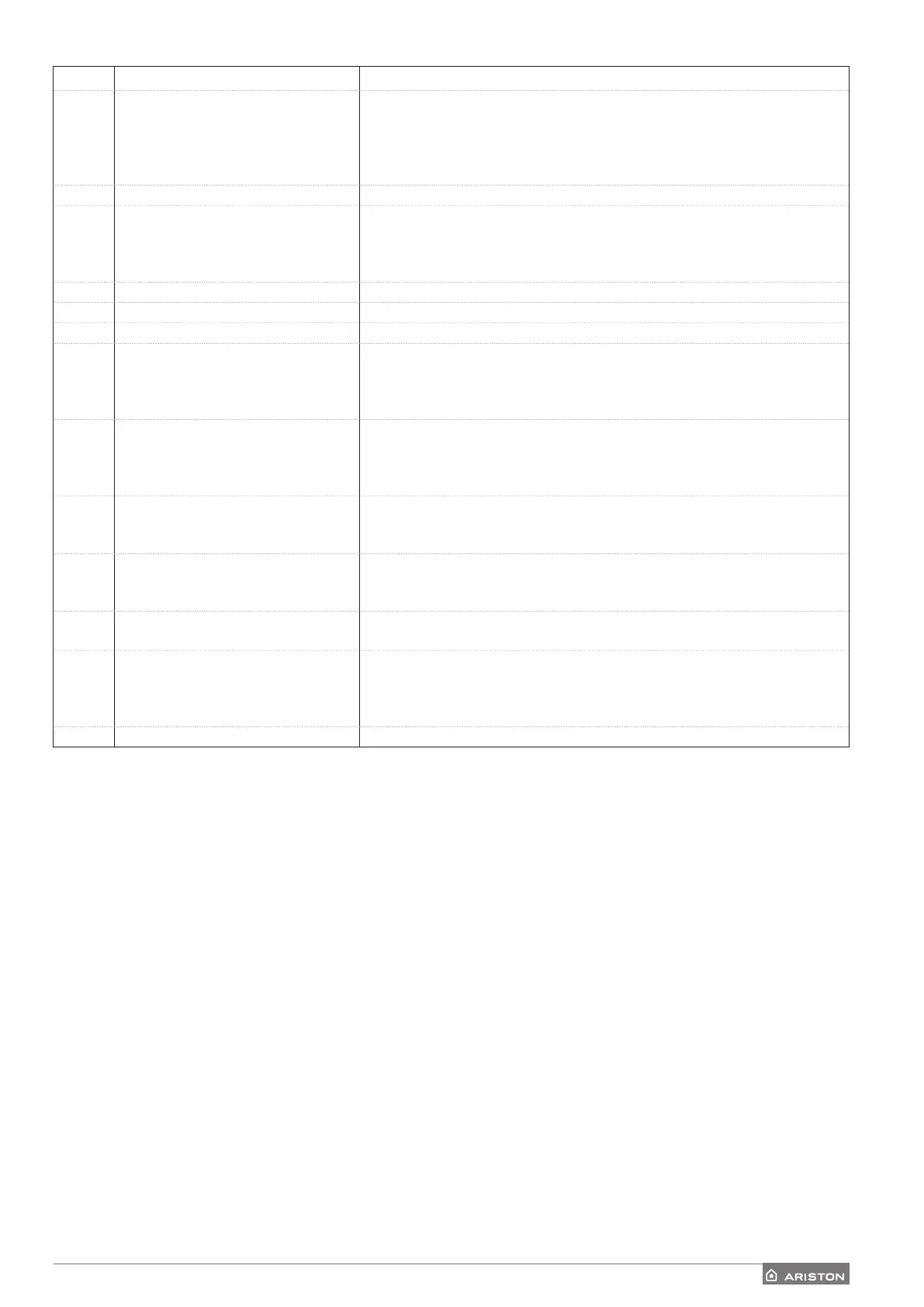

Code Description Resolution

936 Under-floor heating thermostat error Check the flow of the under-floor system. Check the connection of the

thermostat on the IN-AUX2 STE terminal of the Energy Manager and/or STT of

the TDM. If the thermostat of the under-floor system is not present, apply an

electrical jumper to terminal IN-AUX2 STE of the Energy Manager and/or STT

of the TDM.

937 No circulation error Check that the main circuit has activated

938 Anode fault Check the connection of the anode

Check whether there is any water in the indirect cylinder

Check the condition of the anode

Check the configuration of parameter 1.2.6

940 Hydraulic scheme not defined Hydraulic diagram not selected through parameter 1.1.0

955 Water flow check error Check the connection of the flow and return temperature sensors

970 Undefined split / mono config. Check the configuration of parameter 1.2.5

2P2 Thermal cleanse not complete Sanitisation temperature not reached in 6 h:

Check the drawing of domestic hot water during the thermal sanitisation

cycle

Check the activation of the heating element

2P3 DHW setpoint not reached in boost Domestic hot water set-point temperature not reached during the boost

cycle

Check the drawing of domestic hot water during the DHW boost cycle

Check the activation of the heating element

2P4 Electr. heater thermos. (manual) Check the activation of the main circulation pump

Check the flow with the reading of the flow meter through parameter 13.9.3

Check the condition of the safety thermostat and of the cabling

2P5 Electr. heater thermostat (auto) Check the activation of the main circulation pump

Check the flow with the reading of the flow meter through parameter 13.9.3

Check the condition of the safety thermostat and of the cabling

2P7 Precirculation error Check the connection of the flow meter

Run an automatic deaeration cycle 1.12.0

2P8 Low pressure warning Check for any water leakages in the hydraulic circuit

Faulty pressure switch

Defective cabling of the pressure switch. Check the connection of the

pressure switch and replace it, if necessary.

2P9 SG ready input config. err. Only one of the parameters 1.1.0 or 1.1.1 is set as an SG Ready input

Loading...

Loading...