- 123 -

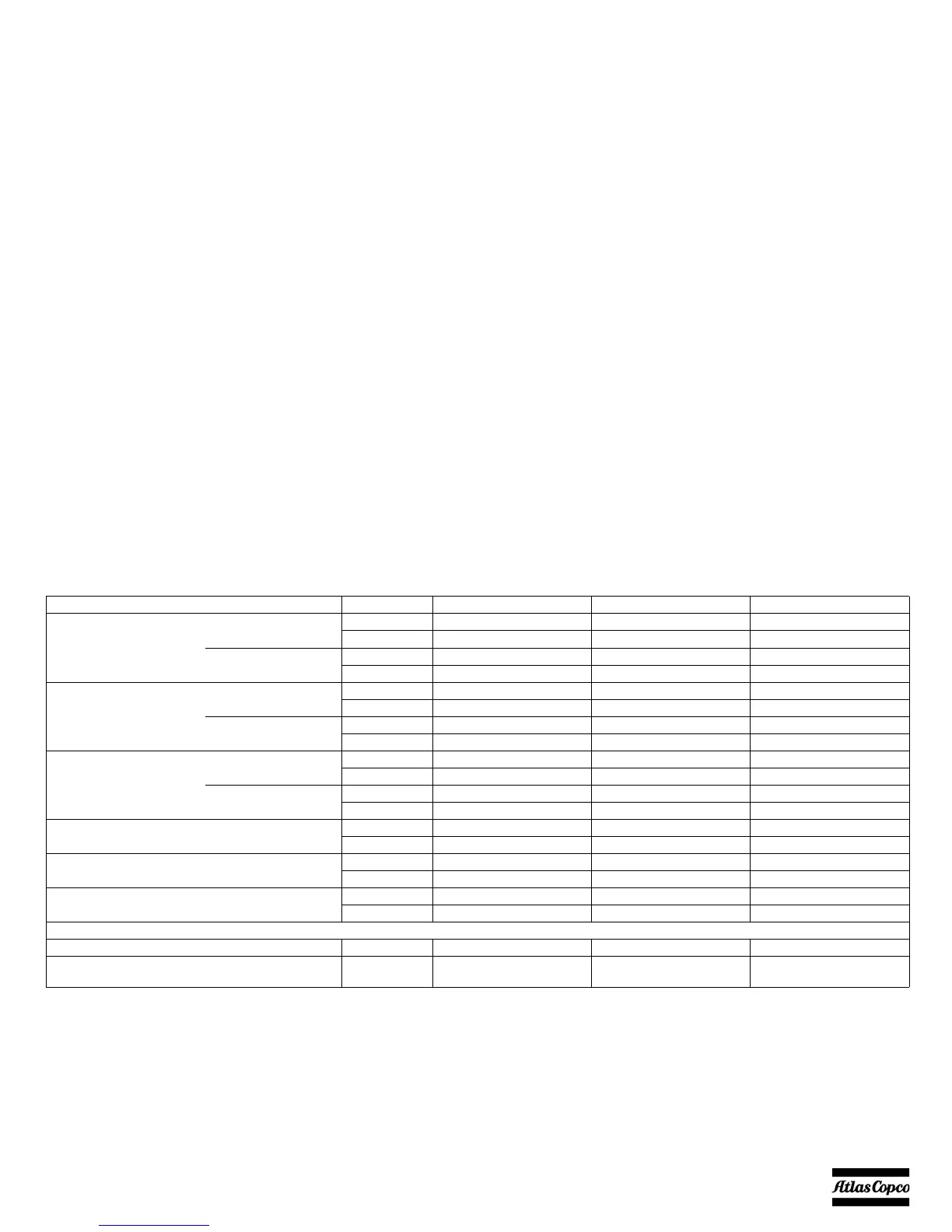

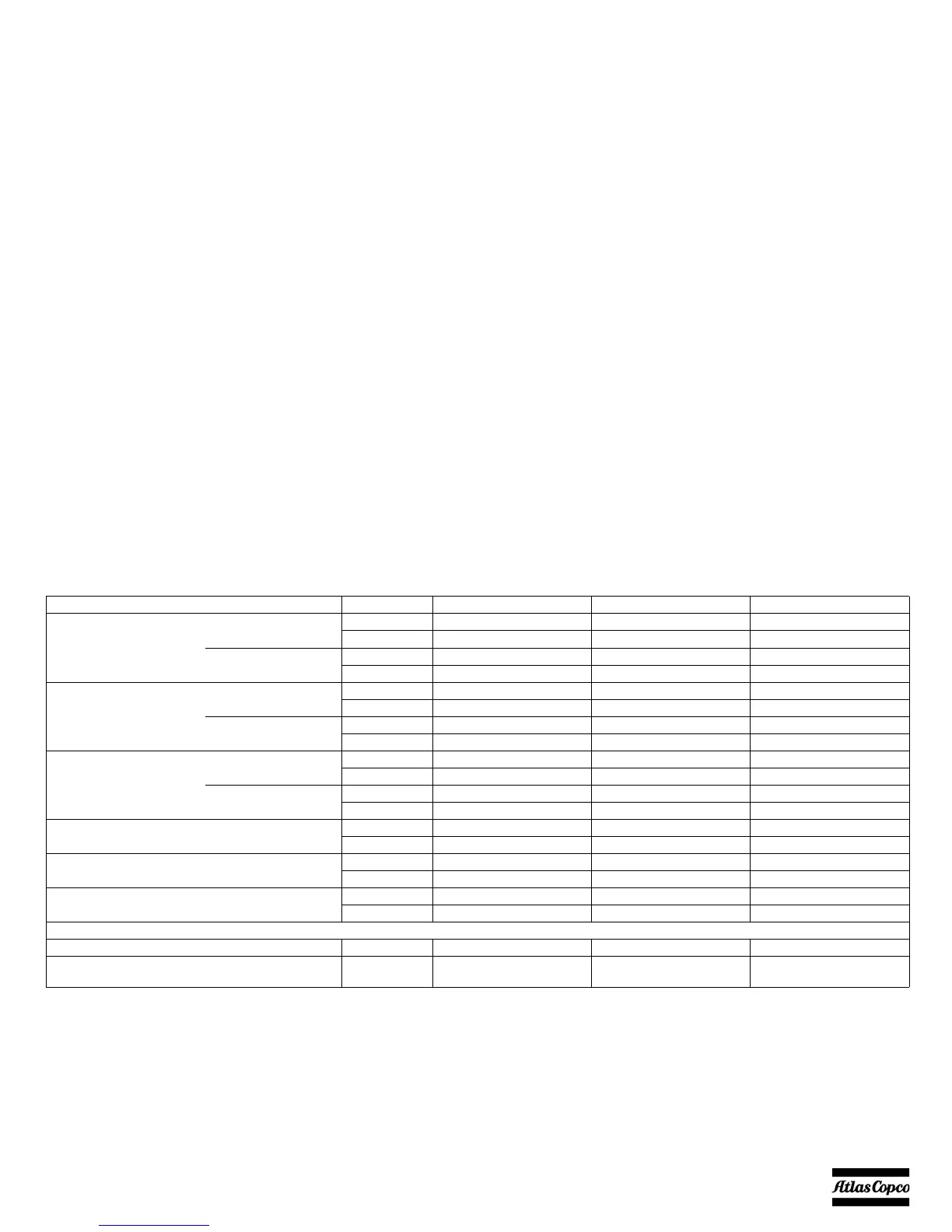

Specific fuel consumption

at 100% FAD

at 25 bar (363 psi)

pressure setting

without aftercooler g/m

3

-36.936.5

lb/1000 cu.ft - 2.30 2.27

with aftercooler g/m

3

-38.138.1

lb/1000 cu.ft - 2.38 2.38

Specific fuel consumption

at 100% FAD

at 30 bar (435 psi)

pressure setting

without aftercooler g/m

3

-37.9-

lb/1000 cu.ft - 2.37 -

with aftercooler g/m

3

-39.2-

lb/1000 cu.ft - 2.45 -

Specific fuel consumption

at 100% FAD

at 35 bar (508 psi)

pressure setting

without aftercooler g/m

3

42 - -

lb/1000 cu.ft 2.62 - -

with aftercooler g/m

3

43.5 - -

lb/1000 cu.ft 2.71 - -

Typical oil content of compressed air mg/m

3

free air 3 3 3

oz/1000 cu.ft 0.003 0.003 0.003

Compressed air temperature

at outlet valve

without aftercooler °C 102 102 102

°F 216 216 216

Air volume at inlet grating (approx.)

3)

m

3

/s 15.1 14.6 16.3

cu.ft/s 530 513 573

Noise level

- Sound pressure level (LP) at 7 m distance dB(A) 80 78 80

- Sound power level (LW) is measured according

to ISO 3744

dB(A) 108 106 108

Designation

XRYS 577 - XRYS 1260 XRXS 607 - XRXS 1275 XRVS 647 - XRVS 1350

1)

Free air delivery is measured according to ISO 1217 ed.4 2009 annex D

Tolerance:

• +/- 5% 25 l/s (53 cfm) < FAD < 250 l/s (530 cfm)

• +/- 4% 250 l/s (530 cfm) < FAD

2)

To account for fuel used during regeneration the fuel consumption values have

to be increased with 1.5%. This is an average percentage and is dependent on

the working conditions of the compressor.

3)

Air required for engine and compressor element cooling, for combustion and

for compression.

Loading...

Loading...