- 83 -

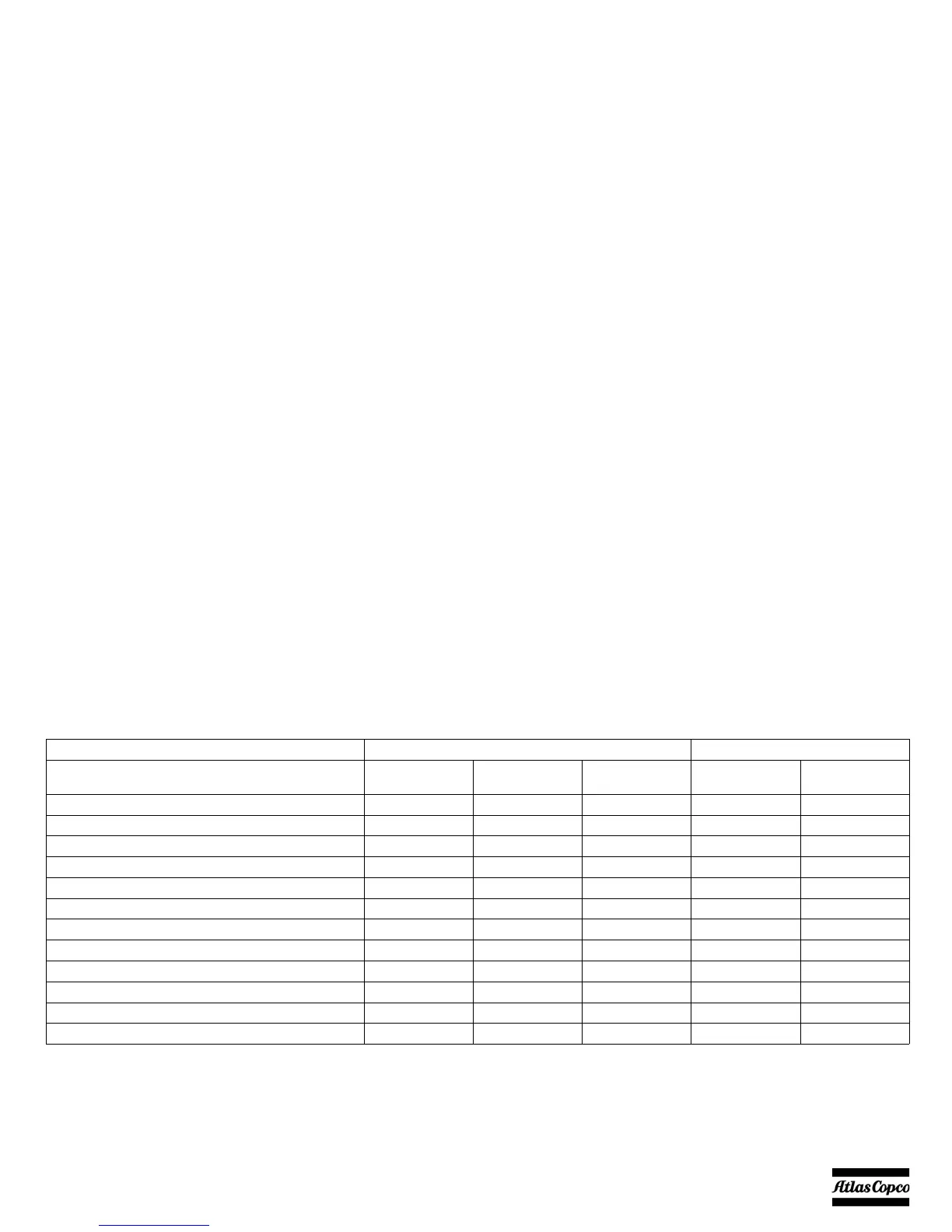

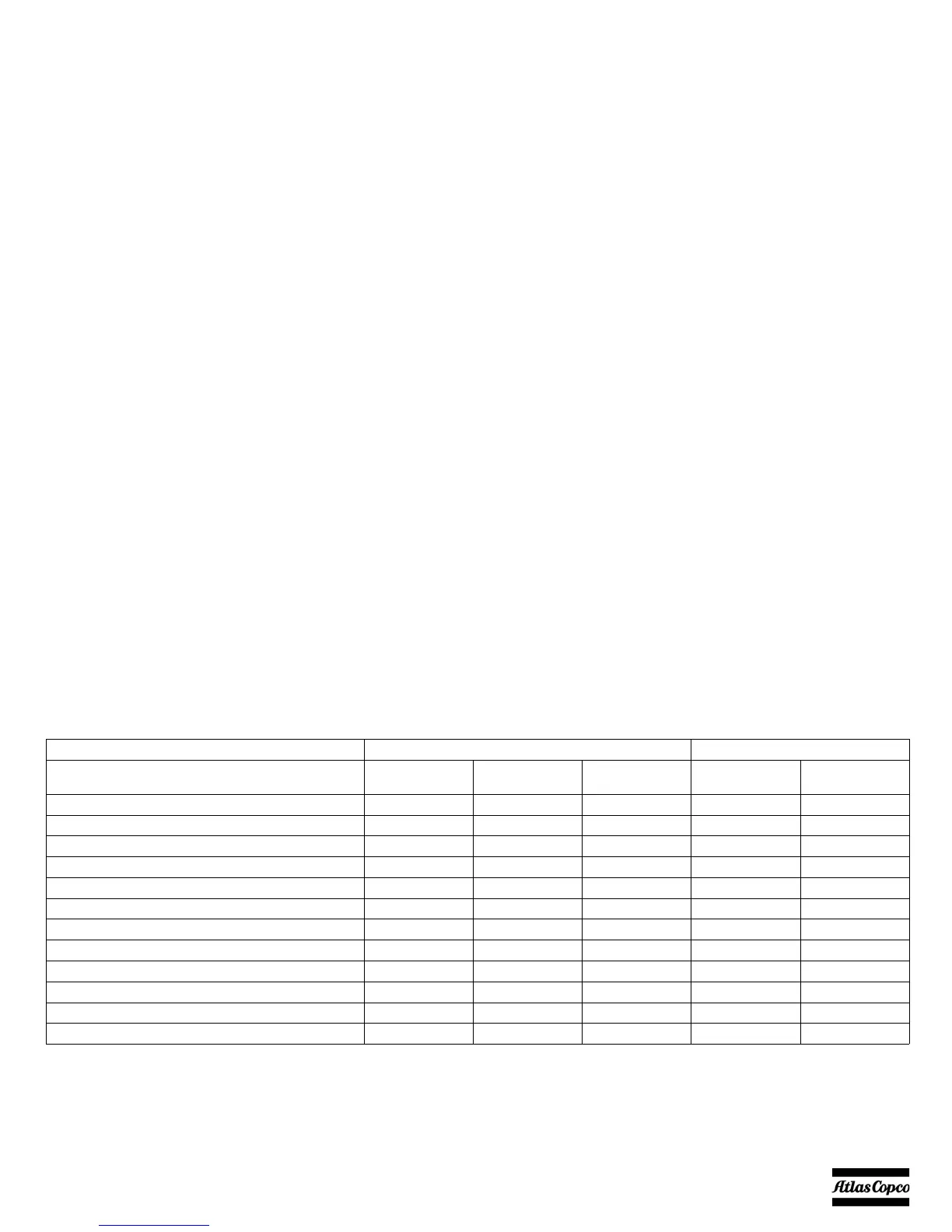

INSPECTION SCHEDULE FOR UNDERCARRIAGE EU

Inspection includes regular checks of individual

components and related action based on these checks.

Lubricating individual components is also part of

regular inspections. Inspection intervals depend on

usage. Defective parts have to be replaced by original

parts.

After 50,000 km i.e. after 12 months of running, the

undercarriage of the compressor has to be inspected

on its operational reliability by an expert.

A check of the vehicle's traffic safety is considered to

have been completed when an expert's report

declaring it free from defects has been submitted in

accordance with the laws of the country involved.

The following details refer to normal use of the

compressor based on a maximum of 50,000 km per

year. Related instructions can be found in the

following subsections.

In principle damaged parts have to be repaired or

replaced.

Any other inspection jobs have to be carried out

regularly by an expert at 6 month intervals.

Inspection list for the expert:

1)

To be performed by skill level 2 Mechanical

technician

2)

To be performed by skill level 3 Electrical

technician

Inspection jobs After the first every

50 km 500 km or first

loaded trip

5,000 km 5,000 km

(fortnightly)

10,000 km

monthly

Check whether wheel nuts are still tight xxxx

Check and if necessary tighten any fixation nuts x x x

Check tyre pressure and wear and tear x x

Inspect brake system

1)

xxx

Check brake adjustment i.e. adjust

1)

xxx

Inspect electrics

2)

x

Check line filters x

Check coupling heads x

Lubricate tow bar xx

Grease nipples x

Check towing eye for wear and tear x

Check frame for cracks and damage x

• Brake system • Tyres

• Wheel bearing • Electrical installations

• Axle • Towing eye

Loading...

Loading...