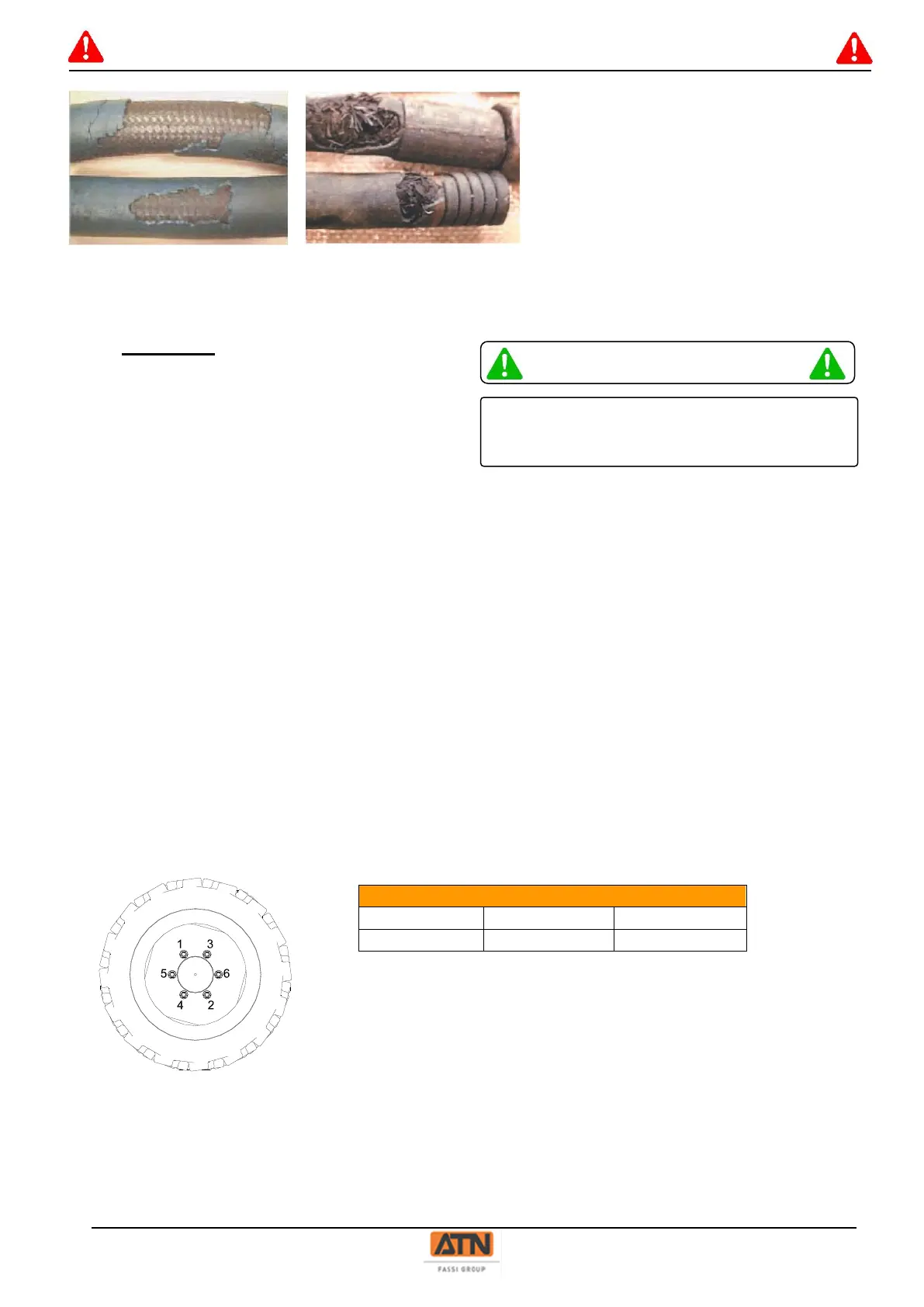

Damaged hoses have to be replaced exclusively with exactly same characteristics hoses

(length, allowed max pressure, diameter, bend radius, hose fittings).

8.4 WHEELS

Wheel torque must be checked after the first 50

hours of operation and every 3 months or 100

operating hours thereafter.

• Criteria for wheels replacement

Damaged rim (deformation or cracks), tire detachment on the rim, snatched stud on

tyres, wear of the tire : >25% of the tire nominal thickness (Z12 : 140mm → 105mm,

Z16 : 150mm → 115mm).

• Wheel replacement

The machine’s stability will be affected if the wheels are not replaced by wheels of identical

characteristics (dimensions, load capacity, flattening under load, disc position, mass…).

The wheel nuts must be torqued and kept at the appropriate torque to prevent the wheels

from becoming loose. The nuts must be tightened with a torque wrench. Excessive torquing

of the nuts will lead to the studs breaking or the thread being deformed.

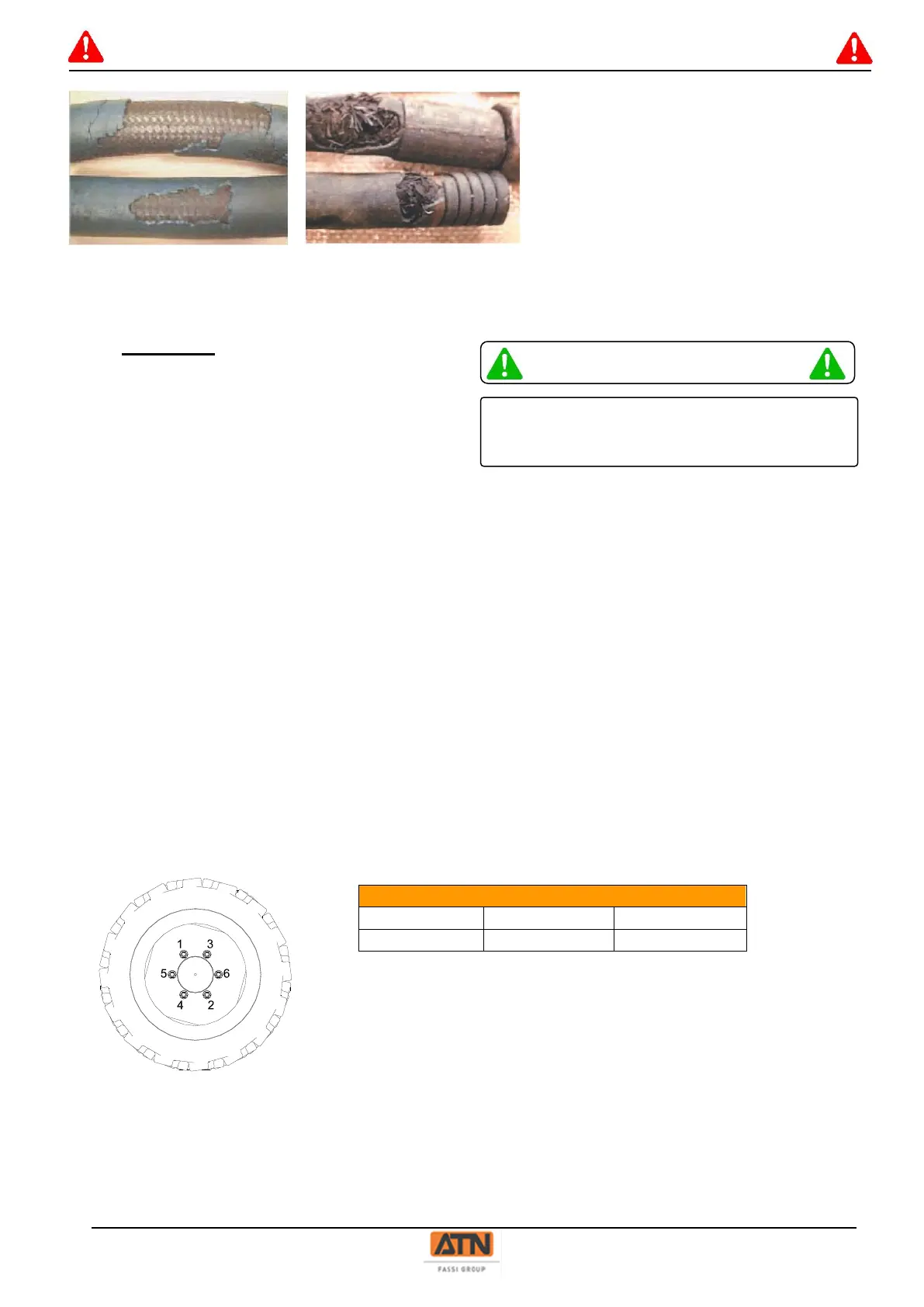

• Wheel tightening

1- Screw all the nuts on by hand. Do not lubricate the threads.

2- Tighten the nuts turn by turn, respecting the order and the tightening steps indicated

below:

Loading...

Loading...