Shenzhen AtomStack Technologies Co., Ltd. support@atomstack3d.com

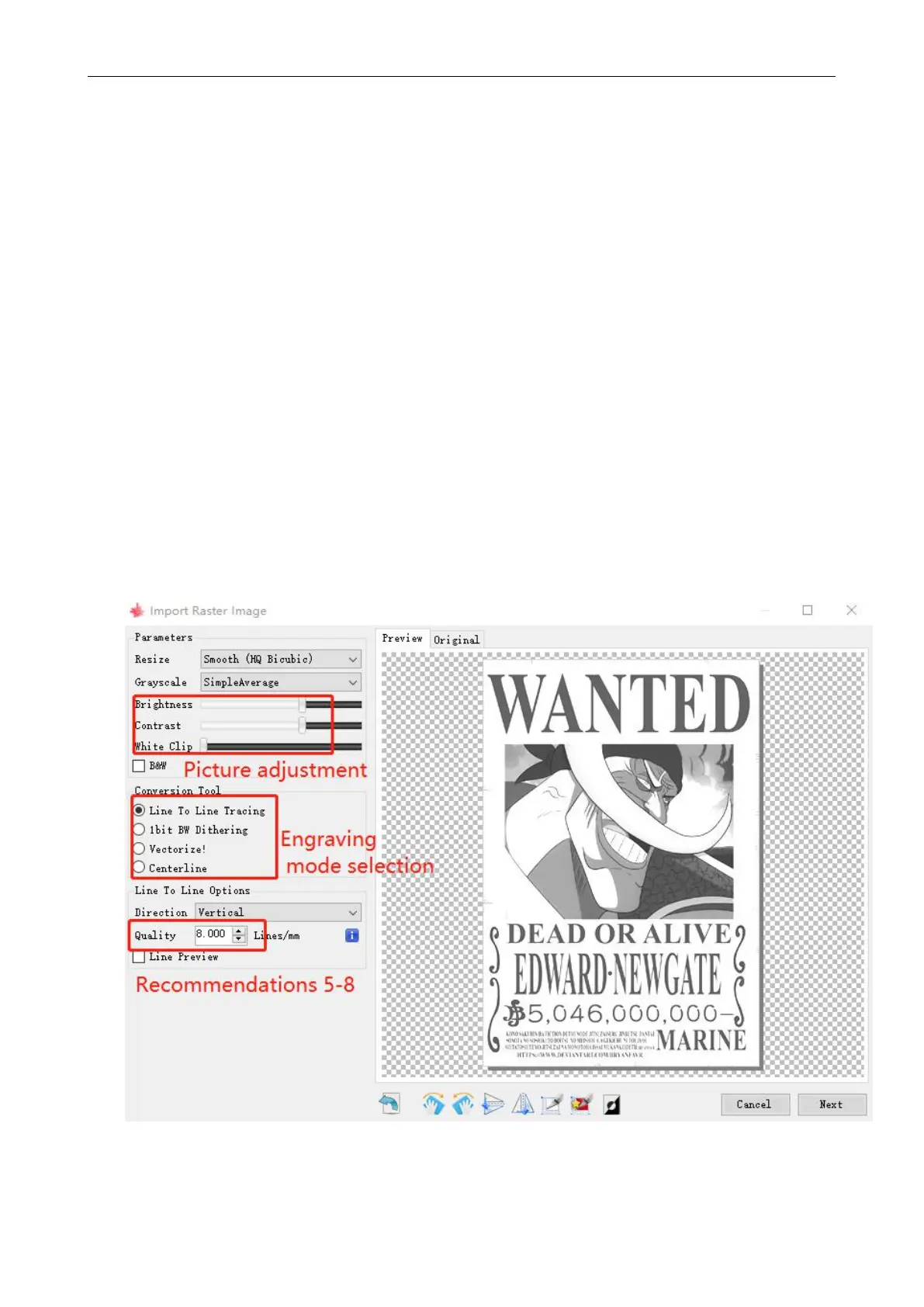

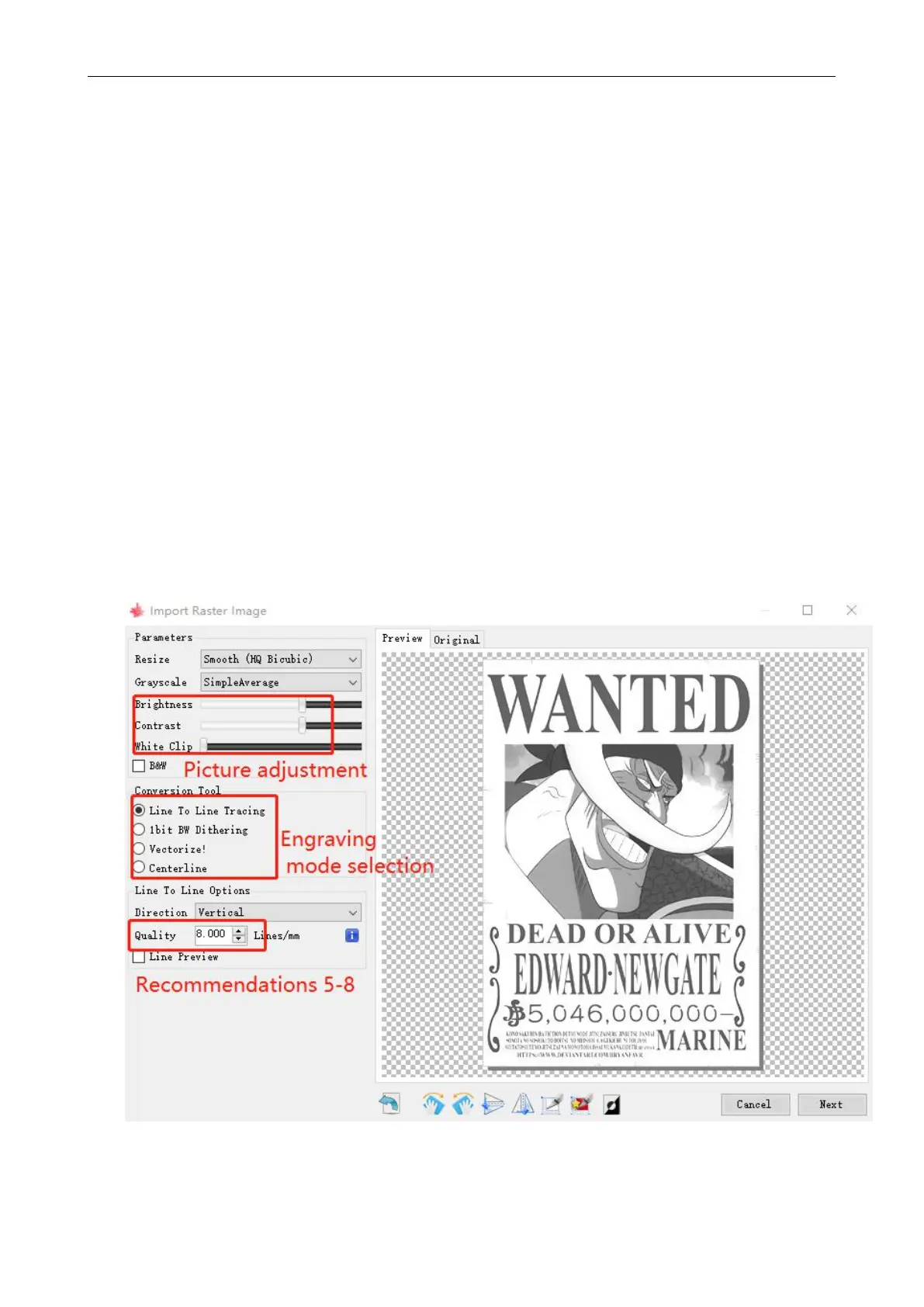

b. Engraving mode usually choose "line to line tracking" and "1bit

dithering", 1bit dithering is more suitable for engraving grayscale graphics.

If you are going to cut, select the vector graphics or centerline engraving

mode.

c. Engraving quality essentially refers to the line width of the laser

scan, this parameter mainly depends on the size of the laser spot of the

engraving machine, AtomStack A5 engraver uses rectangular spot for

0.3*0.5mm, the core energy area of the spot size is about 0.1*0.3mm, so it

is recommended to use the engraving quality range of 5-8, The response to

laser illumination varies from different materials, so the exact value

depends on the specific engraving material.

d. at the bottom of the preview window, the image can also be rotated,

mirror, cut, etc. operations.

e. After completing the above settings, click next to the the settings of

carving speed, carving energy and carving size.

Picture 2.9 Introduction of Setup Interface

C. Engraving speed, engraving energy and engraving size Setting

Loading...

Loading...