MAN - Pyrolytic Oven - REV: Original | D. Installation16

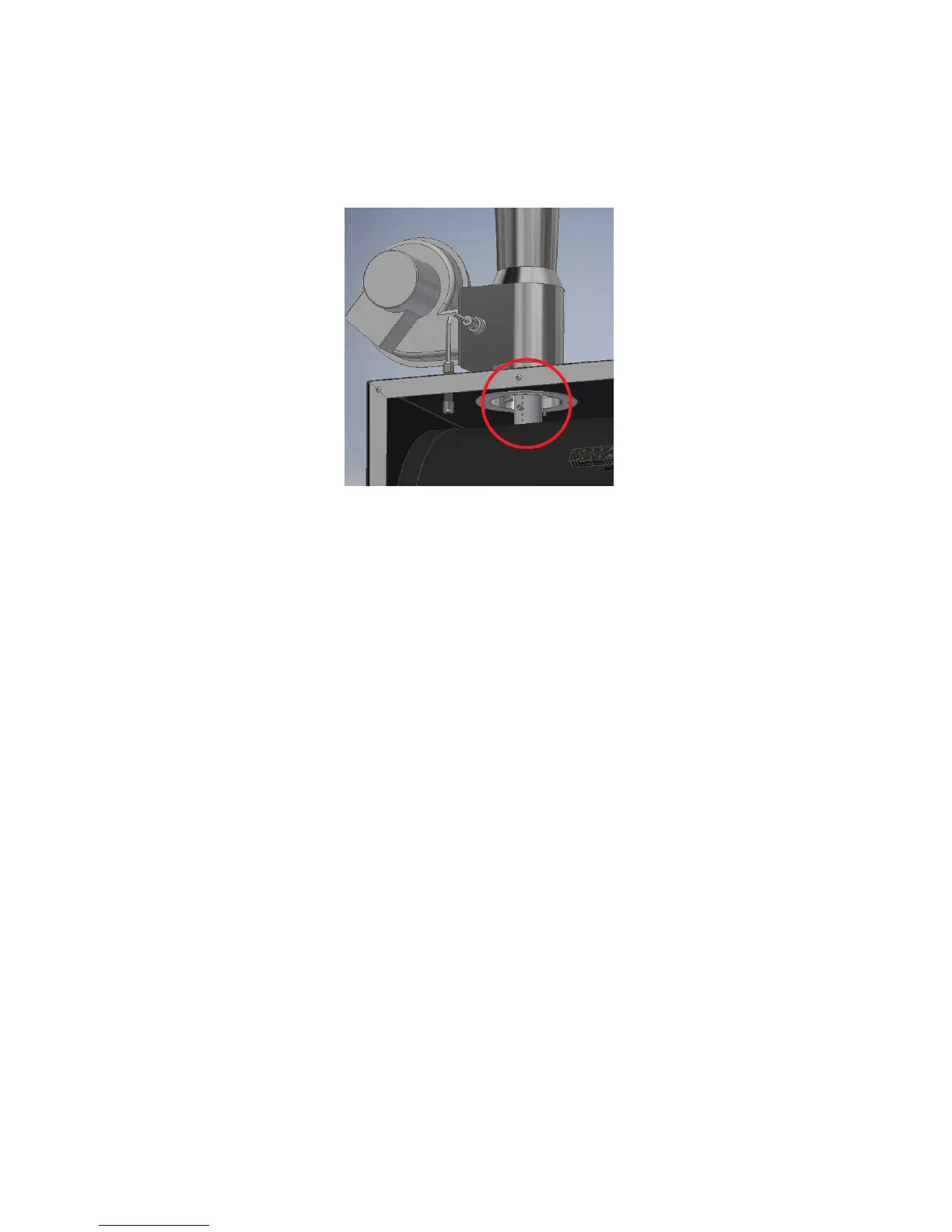

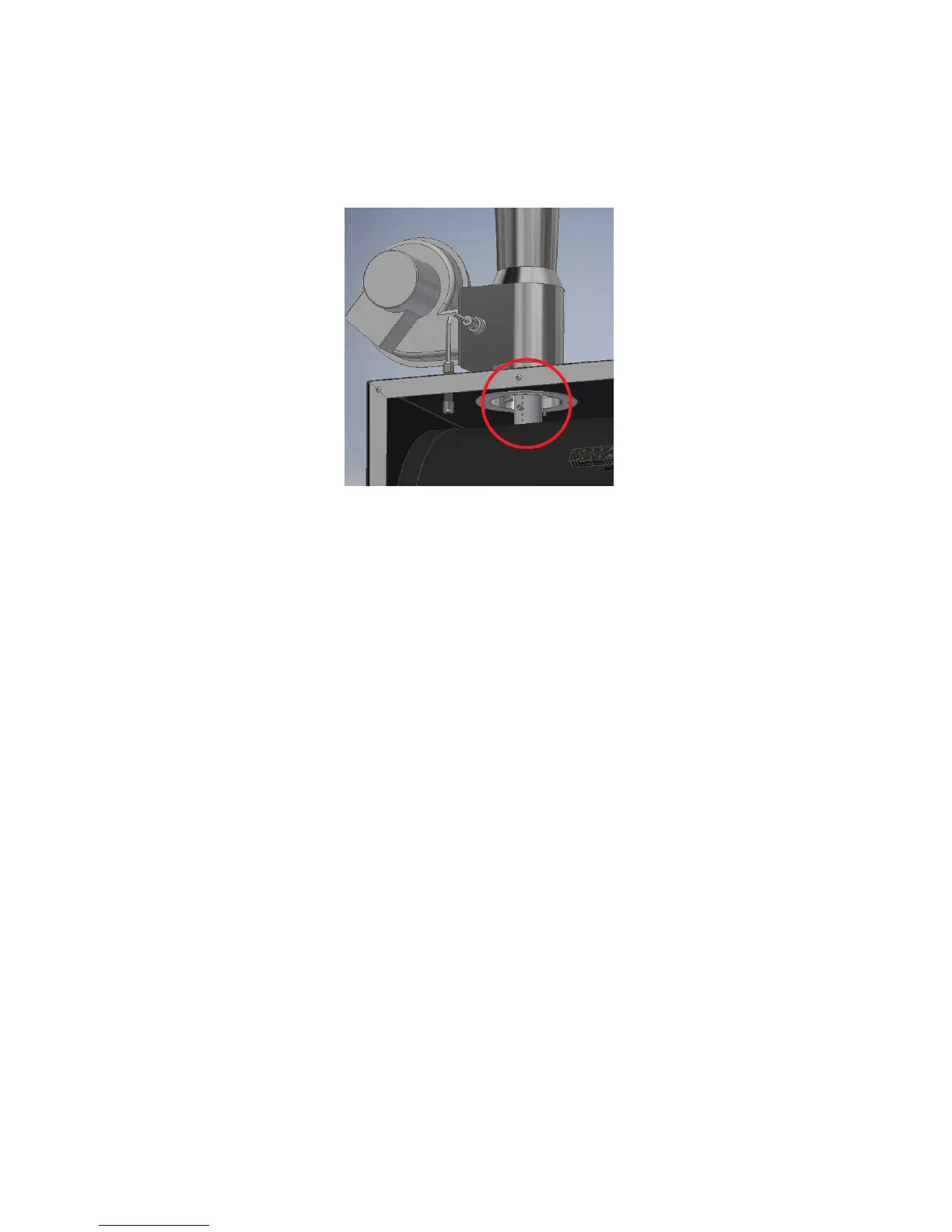

Changing the height of the pipe out of the Oxidizer chamber is done by positioning a screw in the side of the pipe.

The pipe has 5 or 6 holes drilled in it to allow adjustment of the pipe height outside the chamber. The entire pipe can

be pulled out of the Oxidizer chamber (with pliers if the pipe is hot), the screw repositioned to raise or lower the pipe

height. The Draft Inducer must be removed from the top of the unit so you can reach down inside the exhaust duct

with pliers to remove the pipe. The Draft Inducer must be replaced and restarted to measure the oven draft after any

change of the pipe height. See Figure D.1 for pipe location.

It is important to recognize that Pyrolytic Ovens manufactured by ATS are not ordinary ovens. Pyrolytic Oven

systems are specialized, high-temperature systems specically designed and built for thermal cleaning of valuable

objects such as lab glass or metal parts. When organic residues are on the parts being cleaned, pyrolysis gases are

created during the cleaning process.

If the oven pressure is positive instead of slightly negative, these pyrolysis gases may escape into the room and

smoke or odor will be observed.

If the oven pressure is too highly negative then excessive air is sucked through the oven (even though it is tightly

sealed). This excessive leakage rate can prevent the oven from reaching its normal set-point (or struggle to reach its

set-point) and/or ignition of any combustible, pyrolysis gases may occur because of the high oxygen level caused by

excessive draft and leakage.

D.8 Pressure Switch for Draft Inducer Blower Motor

The Pyrolytic Oven is equipped with a pressure sensing switch mounted inside the main control box which senses

the pressure generated by the Draft Inducer when it is running. This pressure switch is interlocked to the oven

heaters so they cannot come on if the Draft Inducer blower motor is not running. If the pressure switch does not

close, then the power relay for the oven heater does not receive power.

The Draft Inducer pressure switch is connected to the Draft Inducer with a short piece of 1/4” metal tubing. This

tubing must be connected for the pressure switch to sense that the blower motor is running.

Figure D.1 - Oxidizer Pipe

Loading...

Loading...