9. Electrical connection Work on the electrical system or equipment must only be

carried out by a skilled electrician himself or by specially

instructed personnel under the control and supervision of

such an electrician and in accordance with the applicable

electrical engineering rules.

9.1 Connection with AUMA plug/ socket connector

.

Check whether type of current, supply voltage and frequency correspond

to motor data (refer to name plate at motor).

.

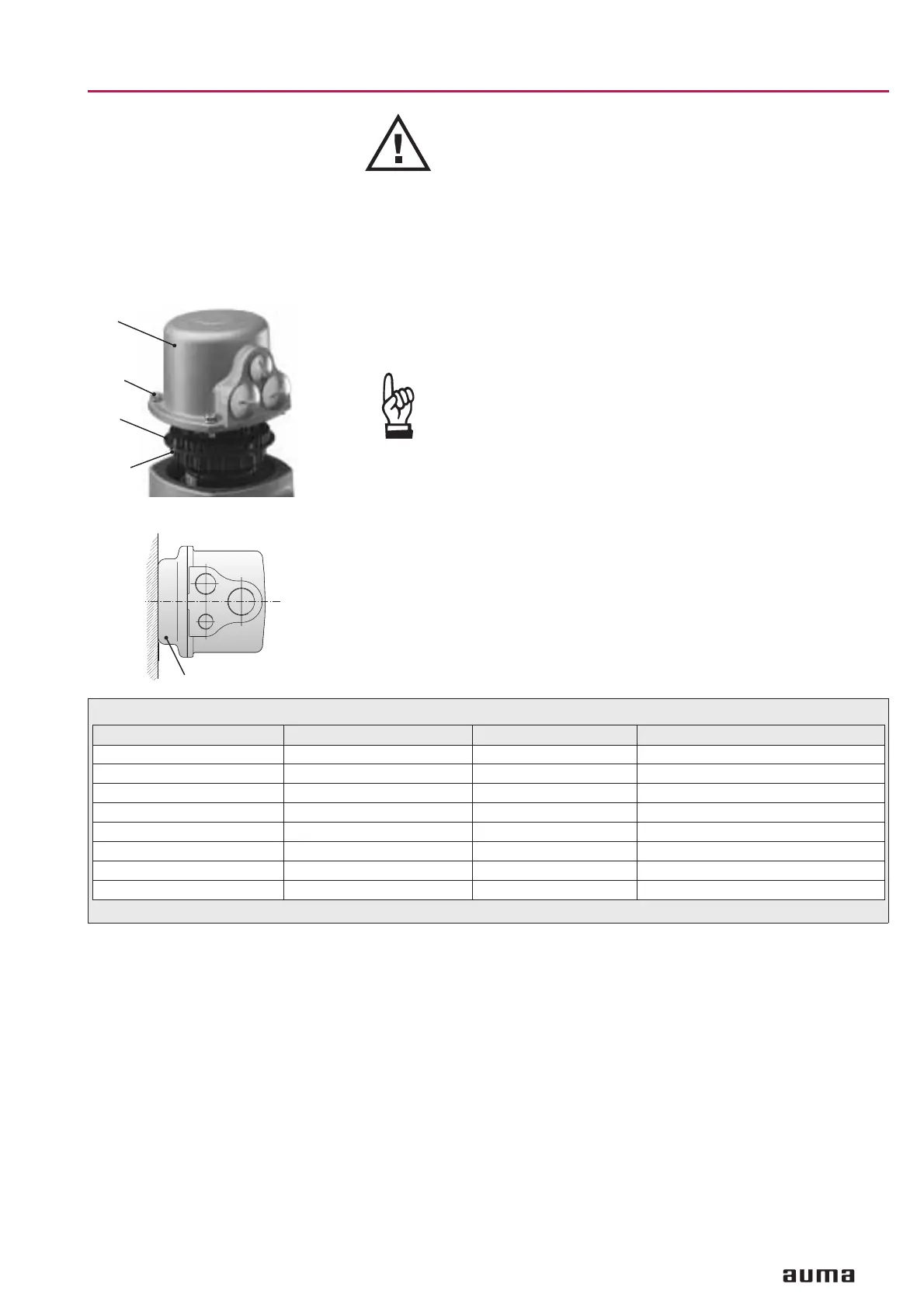

Loosen bolts (26.01) (figure C1) and remove plug cover (26.0).

.

Loosen screws (26.2.5) and remove socket carrier (26.2) from plug cover

(26.0).

.

Insert cable glands suitable for connecting cables.

.

Enclosure protection IP 67 or IP 68 is only ensured if

suitable cable glands are used.

.

Seal cable entries which are not used with suitable plugs.

.

Connect cables according to order related terminal plan KMS . . . . The ter

-

minal plan applicable to the actuator is attached to the handwheel in a

weather-proof bag, together with the operation instructions. In case the

wiring diagram is not available, it can be obtained from AUMA (state com

-

mission no., refer to name plate) or downloaded directly from the Internet

(see page 27).

A special parking frame for protection against touching the bare contacts

and against environmental influences is available (see address list page 28).

9.2 Heater AUMA part-turn actuators have a heater installed as standard. To prevent

condensation, the heater must be connected. Refer to proposed wiring dia

-

grams on pages 19 and 20.

9.3 Motor protection In order to protect against overheating a thermoswitch is embedded in the

motor windings and has to be connected to the external control circuit. The

thermoswitch is tripped as soon as the max. permissible windings tempera

-

ture is reached. After the motor has cooled down to a temperature of approx.

90 °C, the actuator can be switched on again. Our warranty for the motor will

lapse if the thermoswitch is not connected.

9

Part-turn actuators SG 03.3 – SG 04.3

Operation instructions AUMA NORM

Figure C1: Connection

26.0

26.01

26.2

26.2.5

Figure C2: Parking frame (accessory)

Parking frame

Technical data Motor power connections

1)

Protective earth Control pins

No. of contacts max. 6 (3 are used) 1 (leading contact) 50 pins / sockets

Marking U1, V1, W1, U2, V2, W2 according to VDE 1 to 50

Voltage max. 750 V – 250 V

Current max. 25 A – 16 A

Type of customer connection Screws Screw for ring lug Screws

Cross section max. 6 mm

2

6 mm

2

2.5 mm

2

Material:Pin / socket carrier Polyamide Polyamide Polyamide

Contacts Brass (Ms) Brass (Ms) Brass, tin plated or gold plated (option)

1) Suitable for copper wires. For aluminium wires contact AUMA.

Table 3: Technical data AUMA plug/ socket connector

Loading...

Loading...