6. Fasten screws crosswise to a torque according to table.

Table 1: Tightening torques for screws

Tightening torque T

A

[Nm]Screws

Strength class 8.8Threads

25M8

51M10

87M12

214M16

431M20

4.3.2 Output drive type A

Application

●

Output drive for rising, non-rotating valve stem

●

Capable of withstanding thrust

4.3.2.1 Stem nut: finish machining

✔

This working step is only required if stem nut is supplied unbored or with pilot

bore.

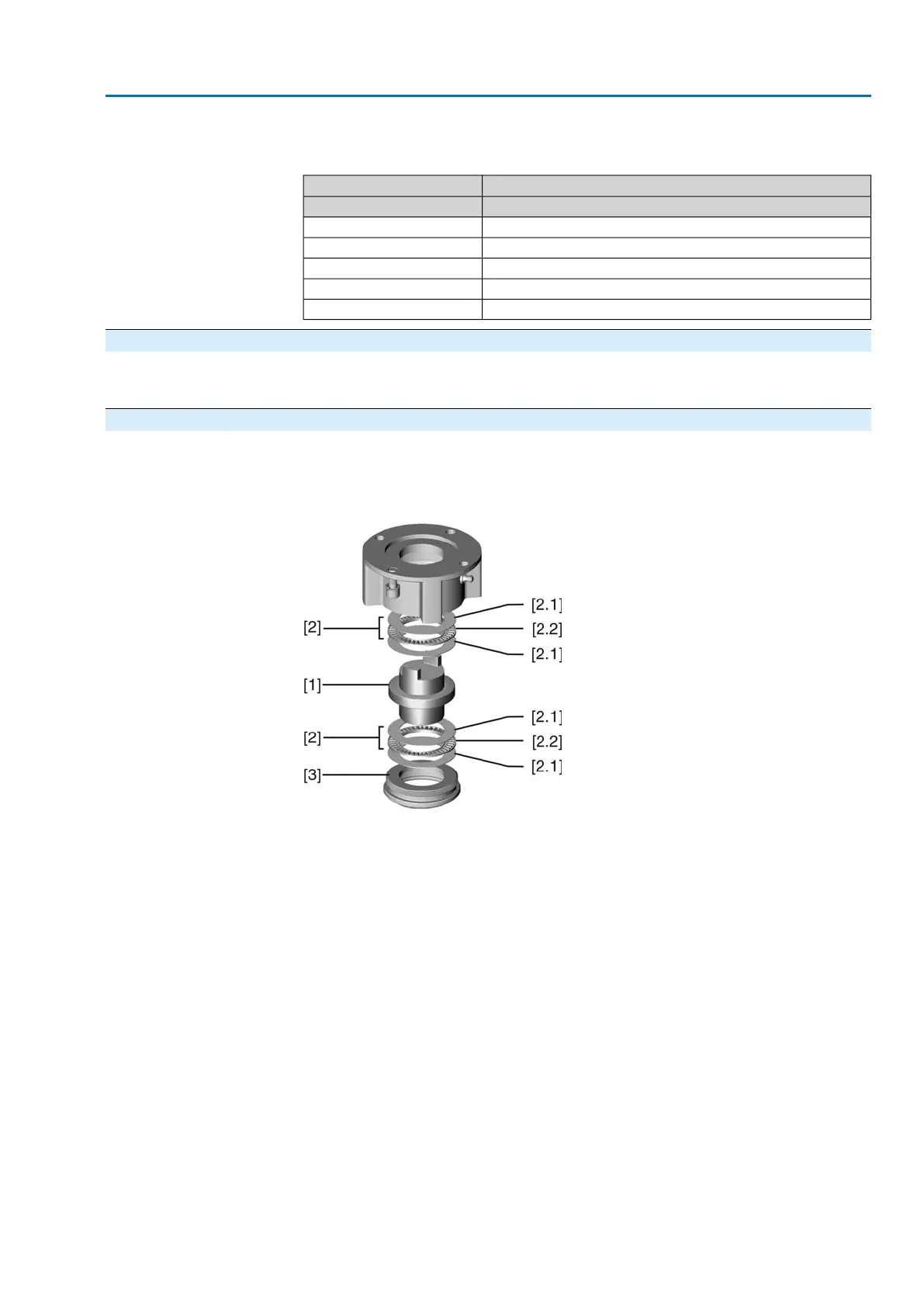

Figure 7: Design of output drive type A

[1] Stem nut

[2] Bearing

[2.1] Bearing race

[2.2] Bearing rim

[3] Spigot ring

1. Remove spigot ring [3] from output drive.

2. Remove stem nut [1] together with bearings [2].

3. Remove bearing races [2.1] and bearing rims [2.2] from stem nut [1].

4. Drill and bore stem nut [1] and cut thread.

Information: When fixing in the chuck, make sure stem nut runs true!

5. Clean the machined stem nut [1].

6. Apply sufficient Lithium soap EP multi-purpose grease to bearing rims [2.2] and

bearing races [2.1], ensuring that all hollow spaces are filled with grease.

7. Place greased bearing rims [2.2] and bearing races [2.1] onto stem nut [1].

8. Re-insert stem nut [1] with bearings [2] into output drive.

Information: Ensure that dogs or splines are placed correctly in the keyway of

the hollow shaft.

9. Screw in spigot ring [3] until it is firm against the shoulder.

13

SA 07.1 – SA 16.1/SAR 07.1 – SAR 16.1 Control unit: electromechanic

AC 01.1 Intrusive Modbus RTU Assembly

Loading...

Loading...