Appendix

38 | P a g e

Appendix I

RoboCrib Controller Commands

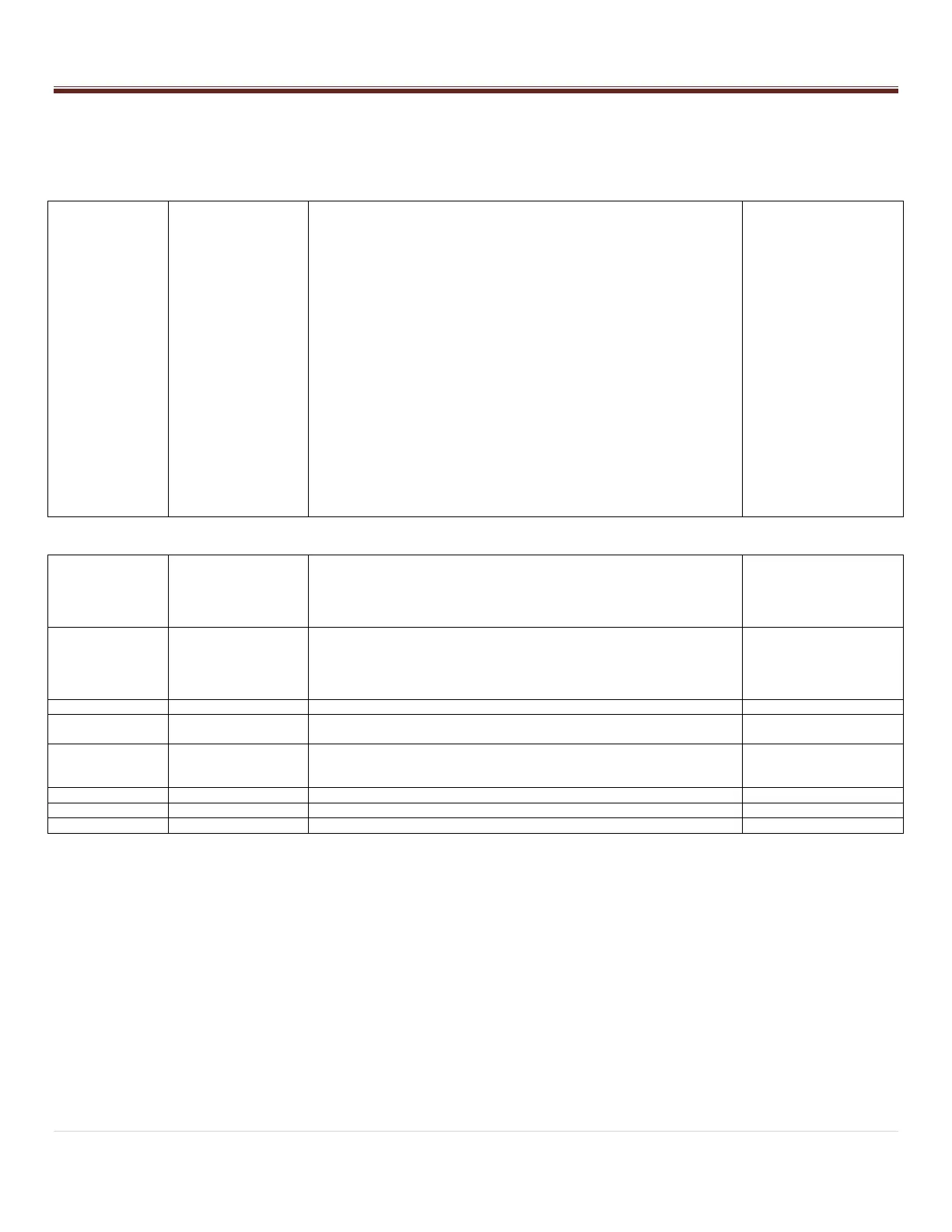

PC Command Description Response Comments

Test

M – Main Platter

L – Large Subplatter

S – Small Subplatter

W – wrap count decremented by 1 from previous value

d – direction always =-1

r – ref error is internal position when ref mark encounter as platter moves CCW

e –value reported has no meaning for this command

s – stall error values have same meaning as FET

TST commands always turn

motors counter clockwise

(CCW) when looking into

backshaft of motor.

w – wrap count set to 1

d – direction always =1

r – reference error has no meaning for this command

e –value reported has no meaning for this command

s – stall error values have same meaning as FET

CAL commands always turn

motors clockwise (cw) when

looking into backshaft of

motor.

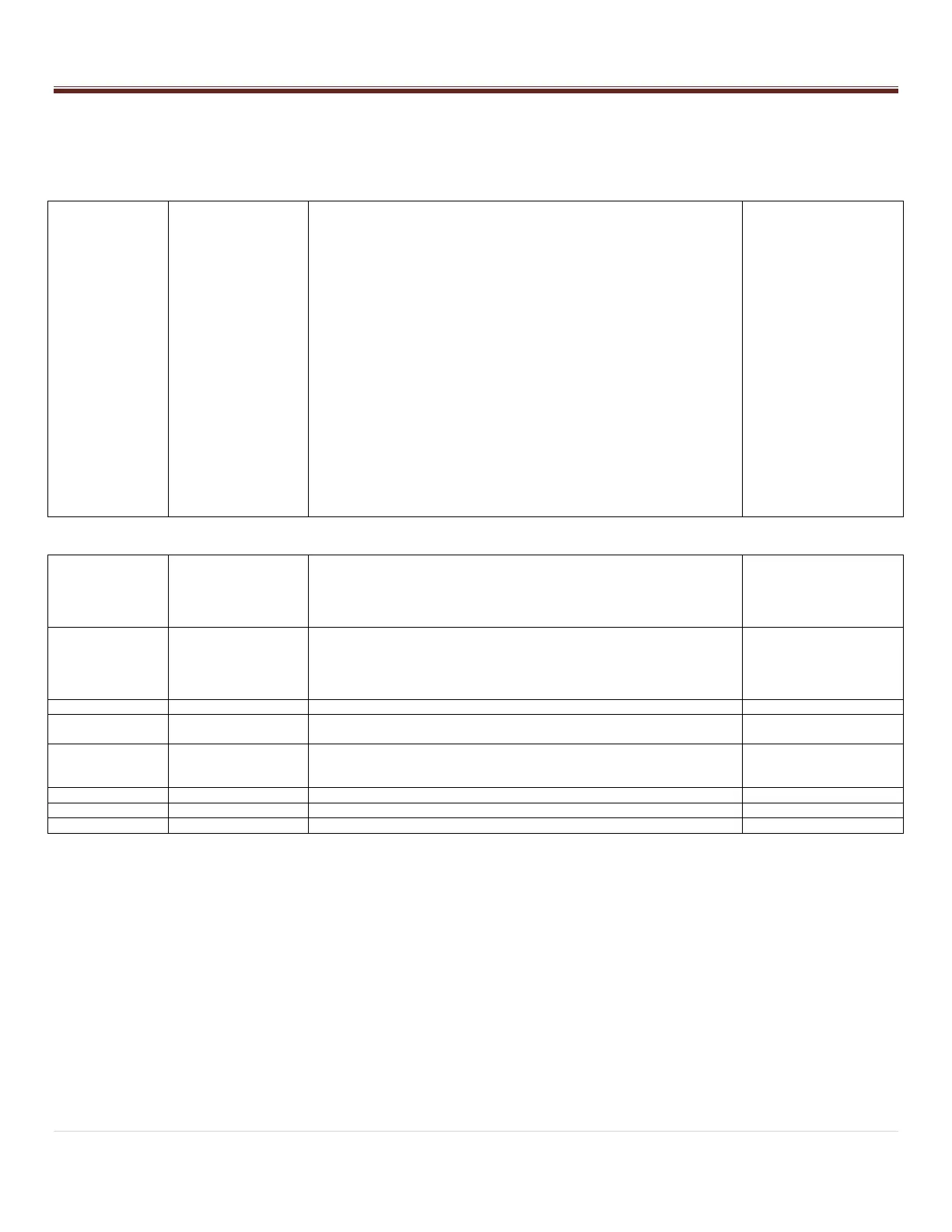

Returns status of all platters using codes shown above for FET

DO-Pxxxx – Door Open where xxxx is HC11 internal MP position in hex

DC – Door Closed

Request Calibration

Status

CC – Calibration Complete – all platters OK

CI – Calibration Incomplete – some or all platters not calibrated

CE – Calibration Error – at least 1 platter has reported a “c-n” error

Solenoid nn activated, all other solenoids deactivated

All solenoids deactivated

Returns the version number and date of the HC11 software.

Note: All values are decimal unless otherwise noted.

Fetch command

abc-Bin to be fetched

a-LSP number

b-SSP number

c-Bin number on

platter

d-Baffle position

c – calibration status

0-not calibrated since power on

1-calibrated

-2-encoder B error so internal position is wrong

-3-platter reference mark not detected so wrap count may be wrong

-4-platter reference mark was detected but was not within ref error limit

-5-baffle pot voltage out of range

w – wrap count (0 or 1)

d – direction (1 for cw/ -1 for ccw)

r – reference error reported when passing ref mark

e – position error between targeted vs actual position

s – stall errors

1 platter never moved or sensors not connected

2 platter started to move, then stopped

3-xxxx platter speed too slow during full-speed part of move

4-xxxx unexpected platter decel during full-speed part of move

5-door open kept platter from moving or stopped it during move

6-baffle motor not working/baffle jammed/pot bad

7-wrap pot voltage limit hit – power to MP/LSP motors cut

8-xxxx platter stall check right after power to motor 1

st

check pt.

9-xxxx platter stall check right after power to motor 2

nd

check pt.

where xxxx is the stall value that caused the stall

The stall values can be

adjusted using the CSn

commands. If a stall

recurs several times

without an obvious cause,

the stall value should be

increased. However,

increasing the value too

much may keep the

platter from stalling when

it should.

An s7 error means that

both MP and LSP motor

power has been turned

off regardless of which

platter has exceeded the

voltage limit. Use

maintenance panel lights

and switches to get the

offending platter back

within legal limits.

Loading...

Loading...