7 — Appendices

Service Instructions RP-A301CE/RP-A351CE/RP-A355CE 7 - 5

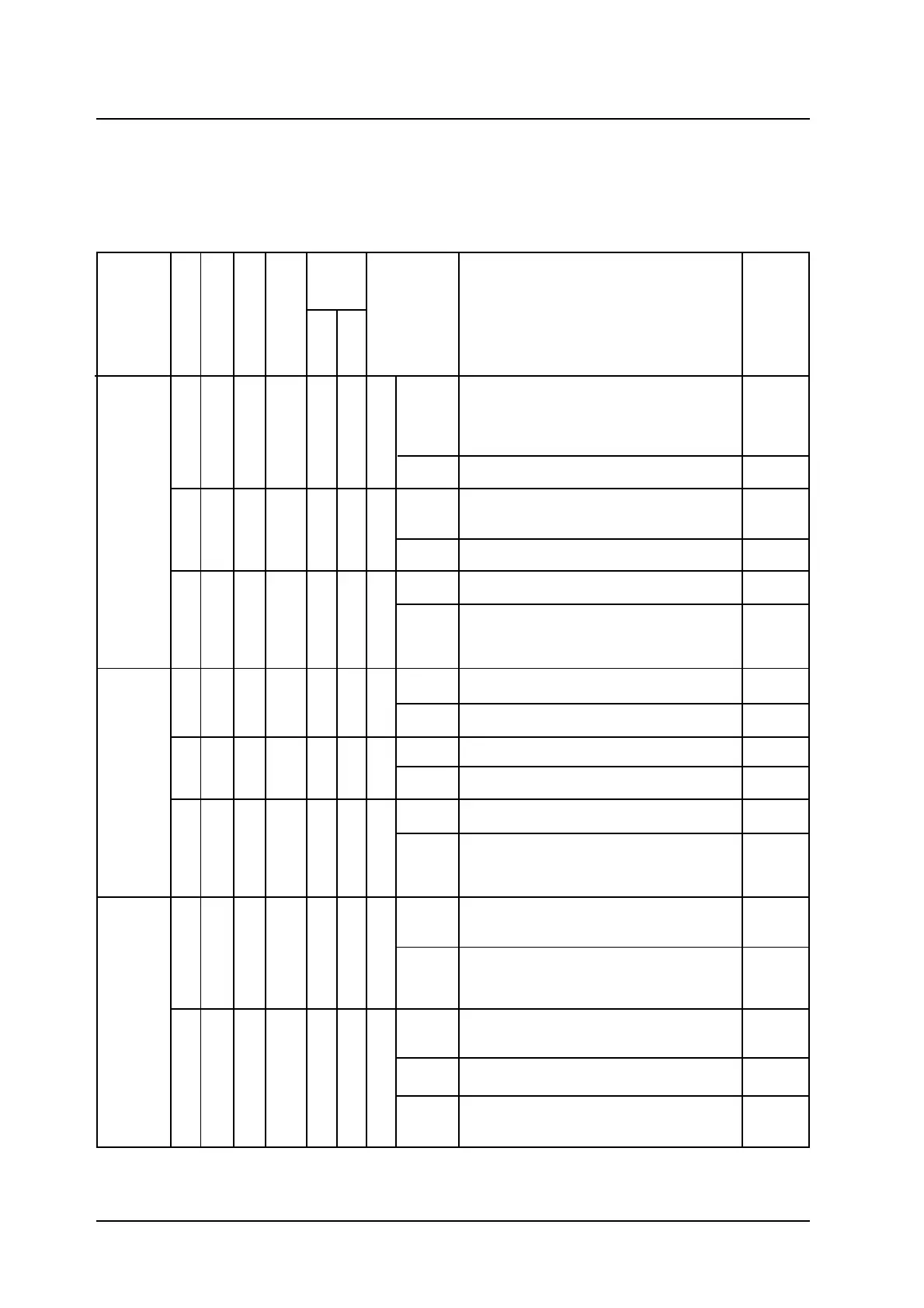

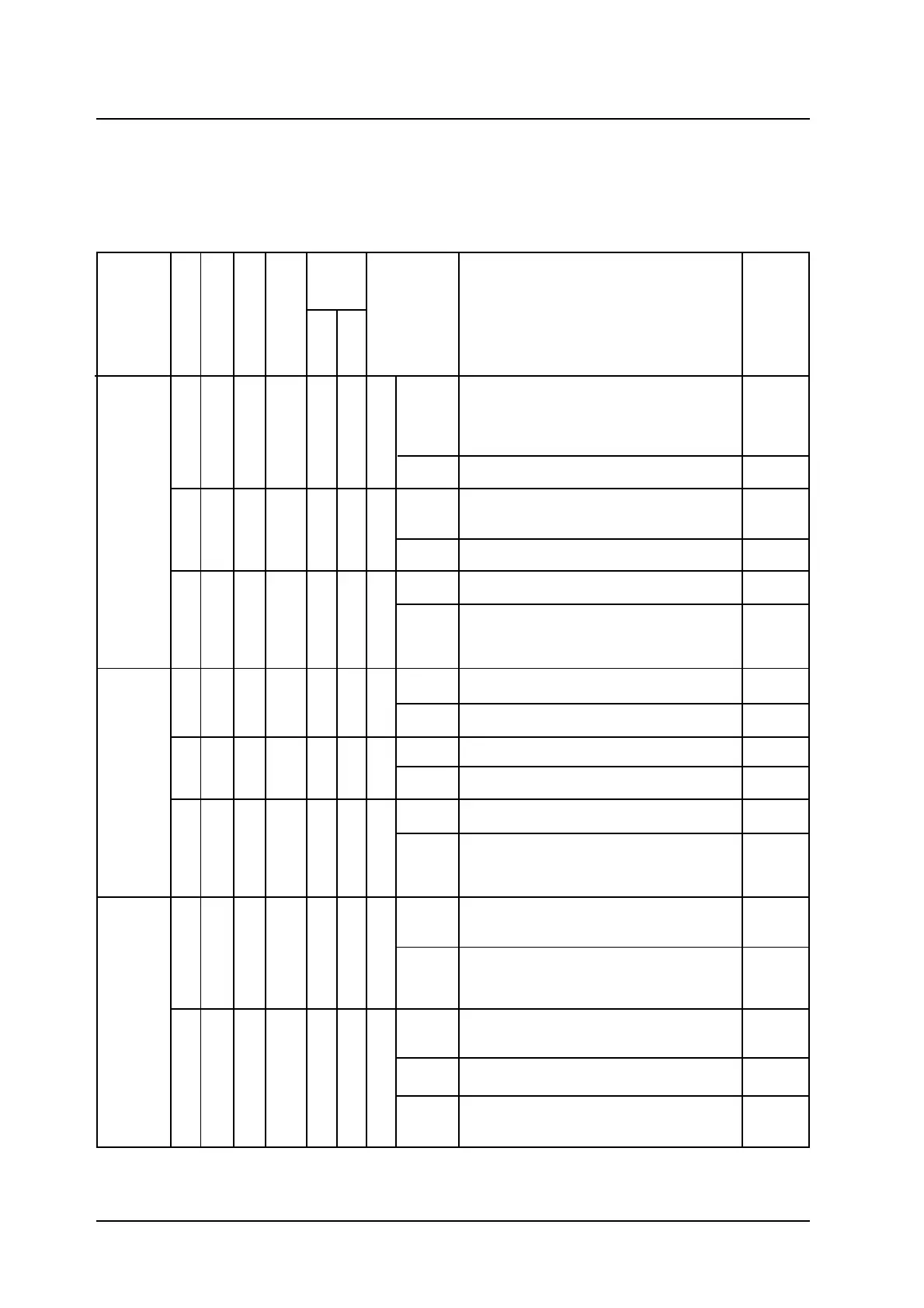

7.3 Common faults/Corrective action

klqbW Before starting any control, turn lk the dip switch 15.

Possible Push- LED no. Parts to check Pos. no.

problems button

Blade A 1 Off 1 Fuses 14A-14B

motor 2 Power cable 19

does 3 Transformer on PCB 16

not run 4 Printed circuit board 18

On Go to checkpoint B

B 3 Off Connection of the blade cover

microswitch and sharpener microswitch 32

On Go to checkpoint C

C 28 4 Off Replace the pushbutton 28

On 1 Relay 17

2 Capacitor 21

3 Blade motor 20

The blade A ON 6 Off Carriage microswitch 31-36

rotates

whereas On Go to checkpoint B

the

carriage B ON 30 8 Off Carriage start pushbutton 30

does not

move On Go to checkpoint C

C ON 30 11A Off Replace the PCB 18

On 1 Integrated circuit MOC 3040 13

2 Printed circuit board 18

3 Carriage motor 25

The blade A ON ON 9 Always Replace the microswitches of stroke end 26

rotates Off

and the

carriage On the Go to check point B

starts stroke

and stops end

at the end

of the B ON ON 11B Turn the stroke adjustment knob to the 34

stroke maximum stroke

beyond

the blade Off Replace the printed circuit board 18

On * Replace the first integrated circuit

M0C 3040 12

*Generally in this position the lamp lights only for a few TENTHS of a SECOND

Checks

Blade motor

Carriage motor

Position of

carriage handle

Blade

Plate

Automatic

Automatic

Automatic AutomaticAutomatic

Loading...

Loading...