6 english

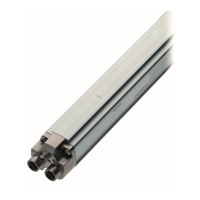

3.1 Construction

Electrical connection: The electrical connection is made

via a connector (see Type code breakdown on page 17).

BTL housing: Aluminum housing containing the

waveguide and processing electronics.

Magnet: Defines the position to be measured on the

waveguide. Magnets are available in various models and

must be ordered separately (see Accessories on page13).

Nominal length: To optimally adapt the transducer to the

application, nominal lengths from 50mm to 7620mm are

available.

3.2 Function

The BTL7 transducer contains the waveguide which is

protected by an aluminum housing. A magnet is moved

along the waveguide. This magnet is connected to the

system part whose position is to be determined.

The magnet defines the position to be measured on the

waveguide.

An internally generated INIT pulse interacts with the

magnetic field of the magnet to generate a torsional wave

in the waveguide which propagates at ultrasonic speed.

The component of the torsional wave which arrives at the

end of the waveguide is absorbed in the damping zone to

prevent reflection. The component of the torsional wave

which arrives at the beginning of the waveguide is

converted by a coil into an electrical signal. The travel time

of the wave is used to calculate the position.

This information is transferred via the PROFINET interface.

PROFINET is an industrial bus system based on the

physical layer of the Ethernet (see www.profibus.com).

The transducer can detect and process up to 16magnets.

The maximum number of magnets depends on the

nominal length. The position and velocity of each magnet

can be output.

Implementation is based on the PNO encoder profile V4.1.

The following functions are also available:

– Number of magnets can be parameterized through the

telegram selection. A fixed number from 1to 16 or

flexible (FMM). In FMM, the number of magnets

corresponds to the number of magnets detected, with

a maximum of16

– Setting the resolution of the position and velocity

output

– Reversal of the measuring direction

– Setting presets/offsets

– Temperature sensor. Read out current, minimum, and

maximum temperature.

Synchronous operation with IRT is possible from a cycle

time of 2ms. The minimum possible cycle time is

dependent on the length and configuration.

Supported PROFINET functions:

– RTC class 1 and 3

– RTA (Real Time Acyclic Protocol)

– DCP (Discover and Configuration Protocol)

– CL-RPC (Connectionless Remote Procedure Call)

– LLDP (Link Layer Discovery Protocol)

– SNMP (Simple Network Management Protocol)

– MRP (Media Redundancy Protocol) Client

Fig. 3-1: BTL7... transducer, construction

3

Construction and function

50

40.6

68

41

36.8

~8011.5 ~80~250 ~250

15

88

3

2xM12

11.5

M8

1) Unusable area

2) Not included in scope of delivery

3) Groove on the top side of the profile marks

the start of measuring range

1)

Nominal length =

Measuring range

BTL5-P-3800-2

magnet

1)

Mounting clamps with insulating bushes and

ISO4762M5x22 cylinder head screws,

max. tightening torque 2Nm

2)

2)

Null point

Groove 3)

End point

BTL7-V50T-M ____ -P-C003

Micropulse Transducer in a Profile Housing

Loading...

Loading...