3. Check the device alignment.

4. Tighten the mounting screws to secure the device (or the device and the bracket) in the aligned position.

Wiring Diagram

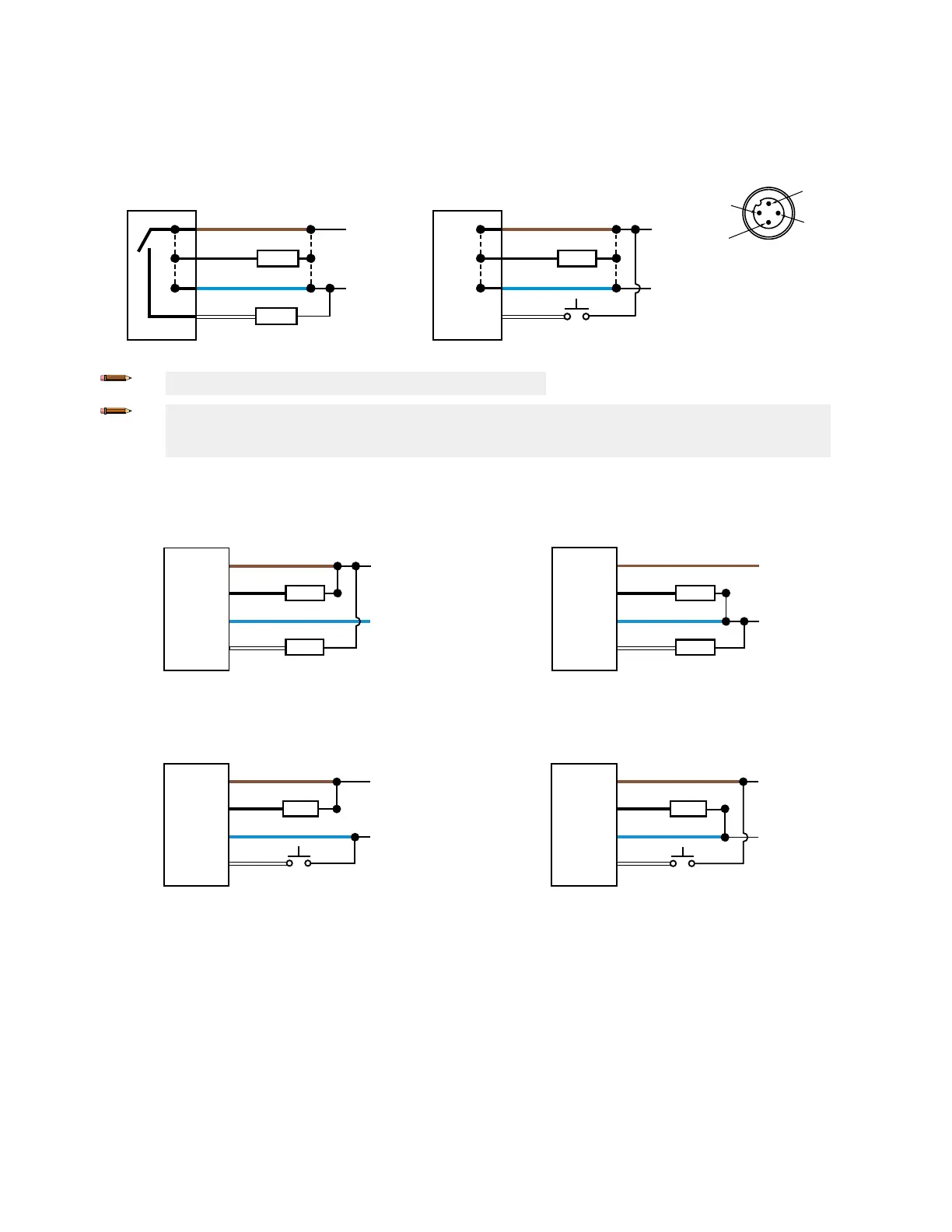

Figure 12. Channel 2 as PNP Discrete or PFM Output

bk (4)

bn (1)

bu (3)

wh (2)

10-30 V DC

CH1

CH2

+

–

PUSH-PULL

Load

Load

Figure 13. Channel 2 as Remote Input

bk (4)

bn (1)

bu (3)

wh (2)

10–30 V DC

CH1

CH2

+

–

PUSH-PULL

Load

Remote

Input

Note: Open lead wires must be connected to a terminal block.

Note: The Channel 2 wire function and polarity is user-selectable. The default for the wire is PNP output. Refer

to the Instruction Manual (p/n 208794) for details regarding use as a remote input or pulse frequency

modulation (PFM) output.

NPN Discrete Outputs

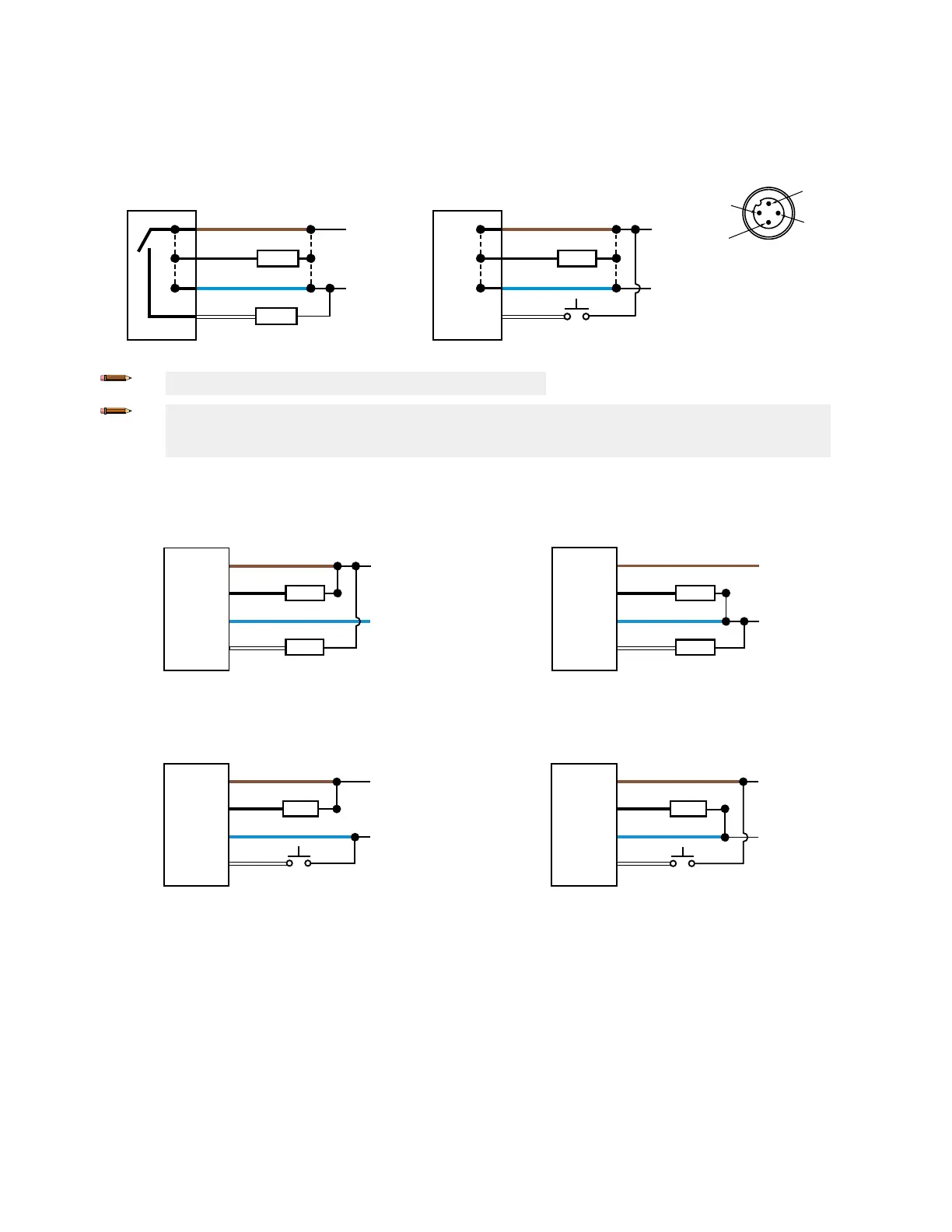

Figure 14. Channel 1 = NPN Output, Channel 2 = NPN Output

bk (4)

bn (1)

bu (3)

wh (2)

10–30 V DC

CH1

CH2

+

–

Load

Load

PNP Discrete Outputs

Figure 15. Channel 1 = PNP Output, Channel 2 = PNP Output

bk (4)

bn (1)

bu (3)

wh (2)

10–30 V DC

CH1

CH2

+

–

Load

Load

NPN Output and Remote Input

Figure 16. Channel 1 = NPN Output, Channel 2 = NPN Remote Input

bk (4)

bn (1)

bu (3)

wh (2)

10–30 V DC

CH1

CH2

+

–

Load

Remote

Input

PNP Output and Remote Input

Figure 17. Channel 1 = PNP Output, Channel 2 = PNP Remote Input

bk (4)

bn (1)

bu (3)

wh (2)

10–30 V DC

CH1

CH2

+

–

Load

Remote

Input

Cleaning and Maintenance

Clean the sensor when soiled and use with care.

Handle the sensor with care during installation and operation. Sensor windows soiled by fingerprints, dust, water, oil, etc. may create

stray light that may degrade the peak performance of the sensor. Blow the window clear using filtered, compressed air, then clean

as necessary using only water and a lint-free cloth.

Q5X Laser Measurement Sensor with Dual Discrete Outputs and IO-Link

4 www.bannerengineering.com - Tel: + 1 888 373 6767 P/N 208795 Rev. G

Loading...

Loading...