Manual 2100-597G

Page 43 of 68

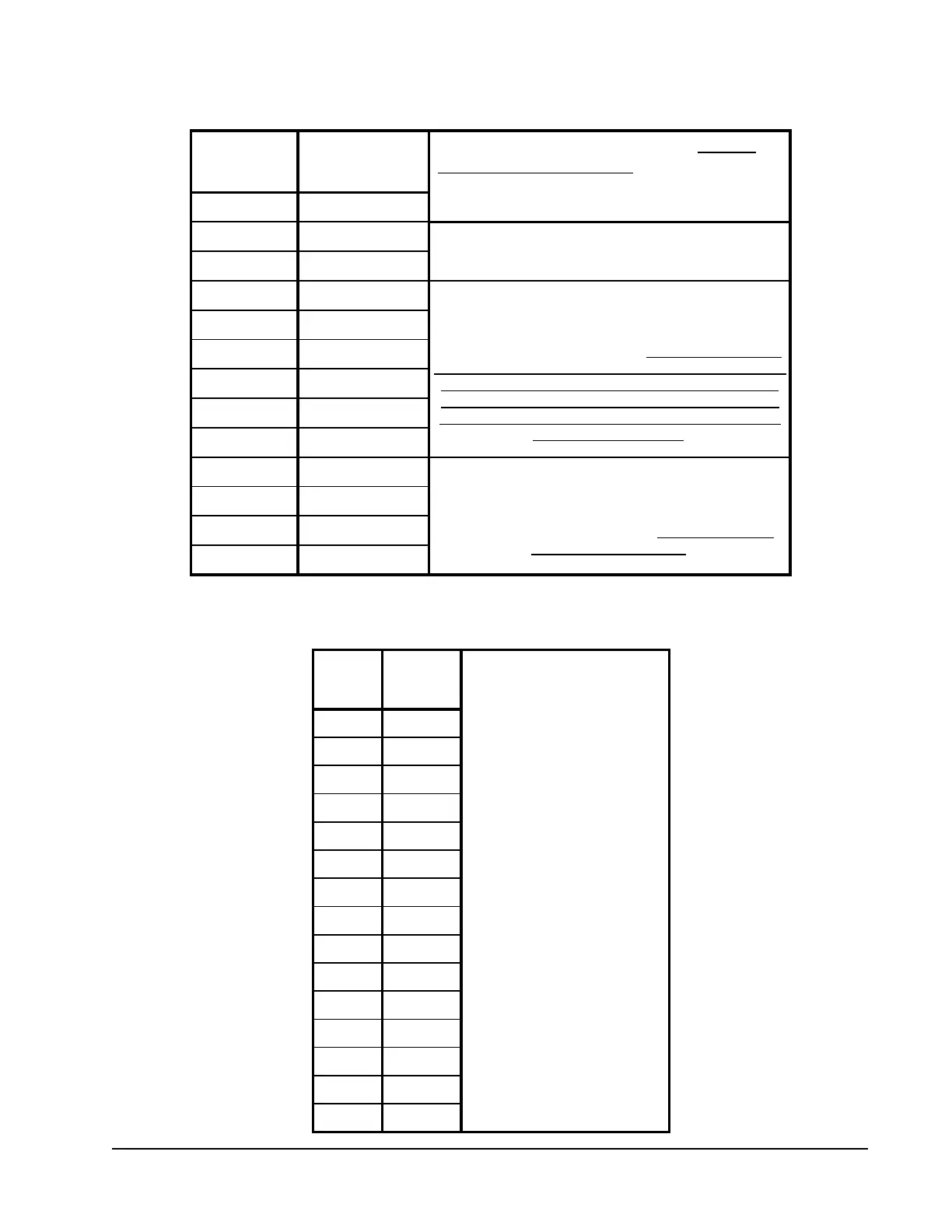

ERV "MANUAL MODE" JUMPER PIN ON "M" Terminal ERV "MODULATING MODE" JUMPER PIN ON "P" TERMINAL

ERV CFM

FLOW INDEX (Light

Blink Code)

Vdc Signal

from CO2

Control

450 100

425 89

400 83

375 76

350 59

325 50

300 40

275 32

250 25

225 12

200 9

175 4

150 1

To adjust the airflow ventilation rate (NO CO2

CONTROL/NON-MODULATING) , determine the "FLOW

INDEX" needed for the intake and exhaust blowers for

the CFM you require.

After determining the air volume

rates needed for the intended

application (Maximum &

Minimum), the table

immediately to the left will allow

for you to program your CO2

control output voltages in

correlation to the CO2 levels you

wish to control when Bard Part #

8403-067 CO2 Control is applied.

1.> Locate two 0-10Vdc Motor Control Boards in control panel

2.> On intake Motor Control Board, observing "GREEN STATUS

LIGHT", turn manual adjust potentiometer (with a small phillips-head

screwdriver) "CCW" to increase "FLOW INDEX" or CW to reduce

"FLOW INDEX" to match desired setting. (NOTE: After long pause,

the green status light will blink long-blinks for the "TEN COUNT" of

the "FLOW RATE INDEX", which then is immediately followed by

fast blinks which indicate the second digit. For example, a Flow

Index of 23 would be two long blinks, followed by 3 fast blinks of

the "GREEN STATUS LIGHT".)

3.> On exhaust Motor Control Board, observing "GREEN STATUS

LIGHT", turn manual adjust potentiometer (with a small phillips-head

screwdriver) "CCW" to increase "FLOW INDEX" or CW to reduce

"FLOW INDEX" to match desired setting. (Same GREEN STATUS

LIGHT blink (refer to Step #5))

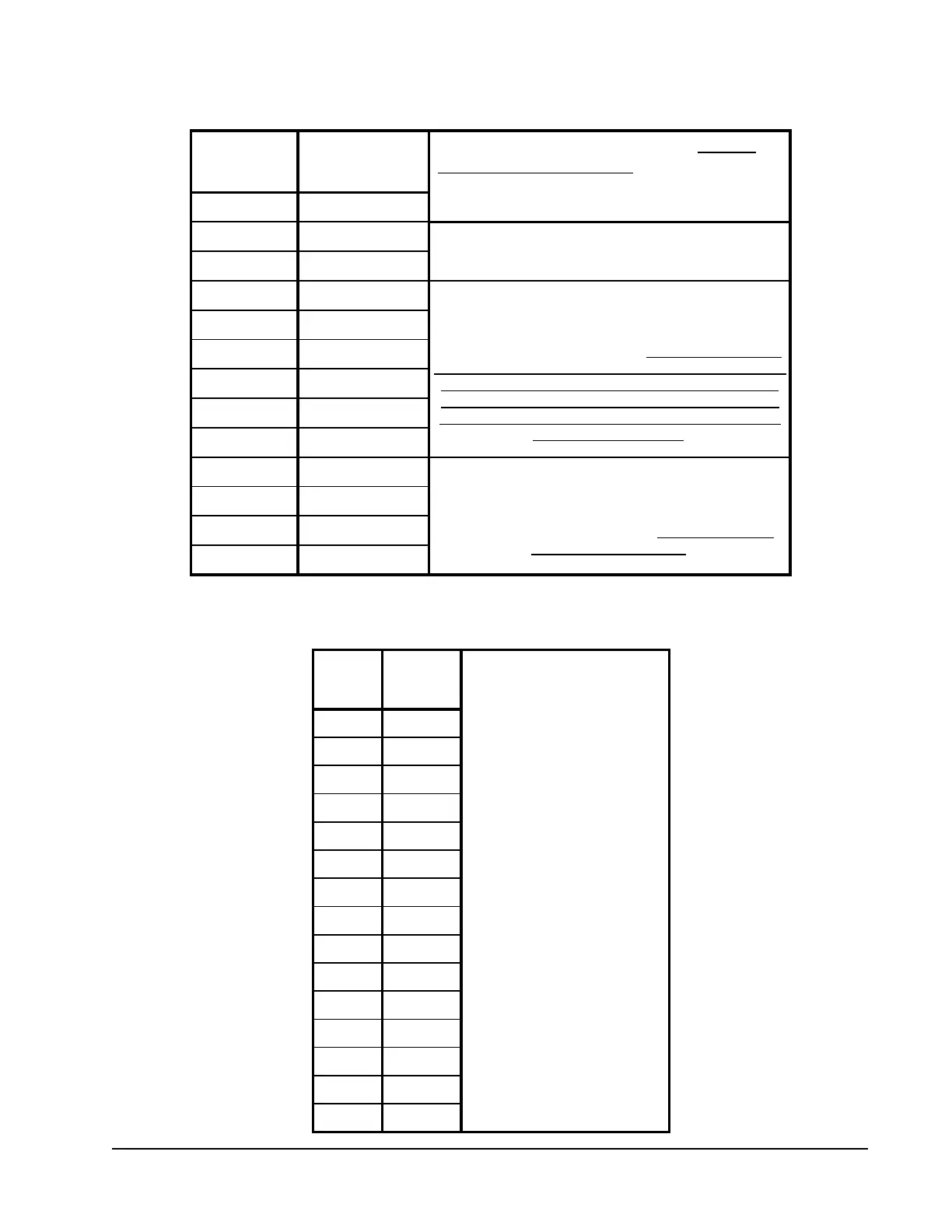

ERV "MANUAL MODE" JUMPER PIN ON "M" Terminal ERV "MODULATING MODE" JUMPER PIN ON "P" TERMINAL

FLOW INDEX (Light

Blink Code)

CFM

from CO2

Control

450

10

425

8.87

400

8.31

375

350

6.73

325

5.91

300

5.15

275

4.58

250

4.06

225

2.91

200

2.57

175

2.24

150

1.74

125

0.96

100

0.77

To adjust the airflow ventilation rate (NO CO2

CONTROL/NON-MODULATING) , determine the "FLOW

INDEX" needed for the intake and exhaust blowers for

the CFM you require.

After determining the air volume

rates needed for the intended

application (Maximum &

Minimum), the table

immediately to the left will allow

for you to program your CO2

control output voltages in

correlation to the CO2 levels you

wish to control when Bard Part #

8403-067 CO2 Control is applied.

1.> Locate two 0-10Vdc Motor Control Boards in control panel

2.> On intake Motor Control Board, observing "GREEN STATUS

LIGHT", turn manual adjust potentiometer (with a small phillips-head

screwdriver) "CCW" to increase "FLOW INDEX" or CW to reduce

"FLOW INDEX" to match desired setting. (NOTE: After long pause,

the green status light will blink long-blinks for the "TEN COUNT" of

the "FLOW RATE INDEX", which then is immediately followed by

fast blinks which indicate the second digit. For example, a Flow

Index of 23 would be two long blinks, followed by 3 fast blinks of

the "GREEN STATUS LIGHT".)

3.> On exhaust Motor Control Board, observing "GREEN STATUS

LIGHT", turn manual adjust potentiometer (with a small phillips-head

screwdriver) "CCW" to increase "FLOW INDEX" or CW to reduce

"FLOW INDEX" to match desired setting. (Same GREEN STATUS

LIGHT blink (refer to Step #5))

FIGURE 24A

CRV “Manual Mode” Jumper Pin on “M” Terminal

FIGURE 24B

CRV “Modulating Mode” Jumper Pin on “P” Terminal

Loading...

Loading...