Manual 2100-597G

Page 66 of 68

FAN BLADE SETTING DIMENSIONS

The position of the fan blade should be flush with the

leaving face of the orifice plate. Check to make sure

the blades do not extend beyond the rear casing of the

unit. Spin the blade by hand to make sure it does not

hit the ring.

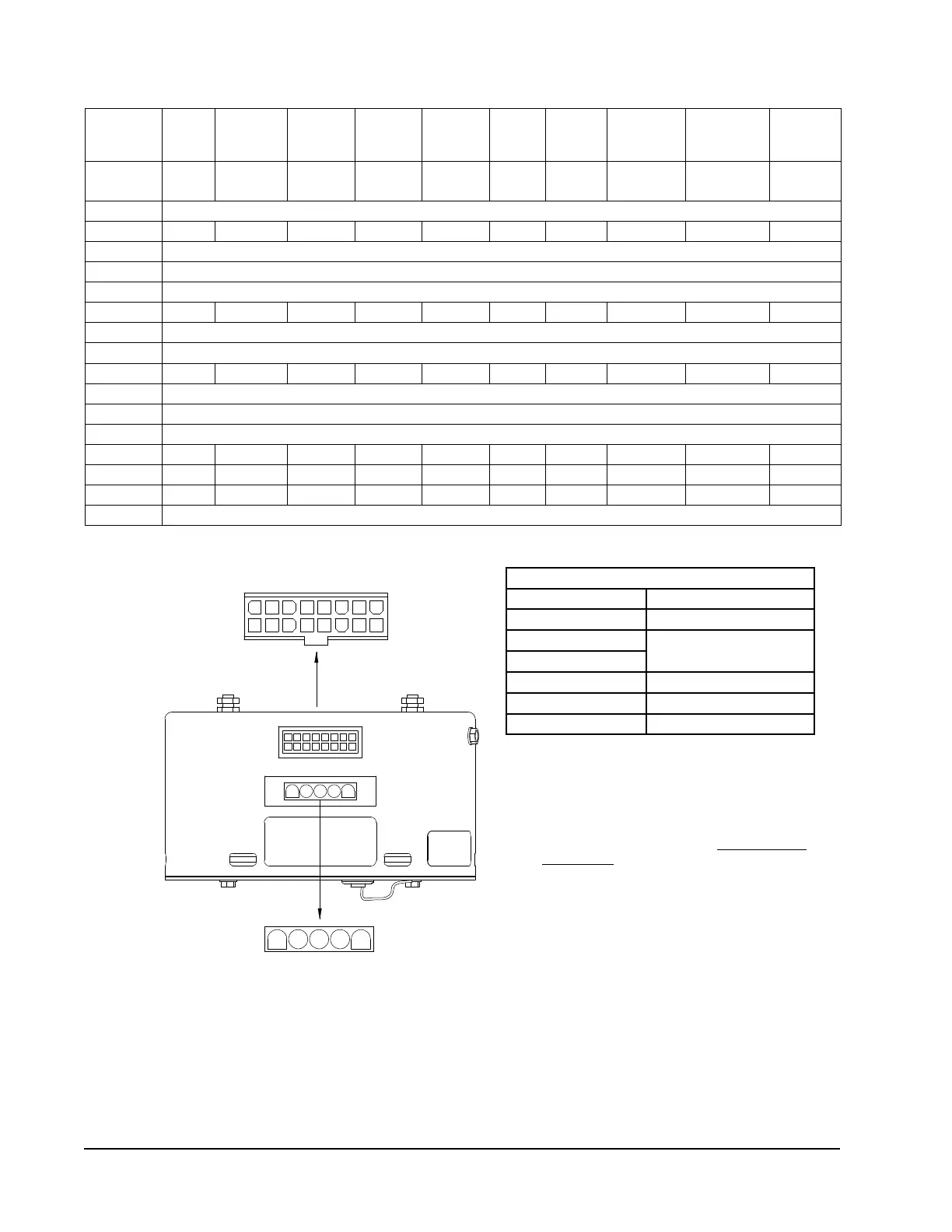

MODE of

OPERATION

OFF

Continuous

Blower

(Ventilation

Mode)

Part Load

Cooling

Full Load

Cooling

Dehum.

Mode

(when

equipped)

Part

Load

Heat

Pump

Full

Load Heat

Pump

Heat Pump

Full Load w/

1st Bank of

Elec. Heat

Heat Pump Full

Load w/ 1st &

2nd Bank of

Elec. Heat

Emergency

Heat Mode

Thermostat

24 VAC

Inuput Signals

— "G"

"G",

"Y1","Y2"

"G",

"Y1","Y2"

"D"

"G", "B",

"Y1"

"G", "B",

"Y1", "Y2"

"G", "Y1",

"Y2", "B",

"W1"

"G", "Y1", "Y2",

"B", "W2",

"W3"

"G",

"W2", "W3"

Pin #1 24 VAC "C" (Common) Signal, Always Energized

Pin #2 X

Pin #3 24 VAC "C" (Common) Signal, Always Energized

Pin #4 Not Used

Pin #5 Not Used

Pin #6 X X X X X X X

Pin #7 Not Used

Pin #8 Not Used

Pin #9 X X X

Pin #10 Not Used

Pin #11 Not Used

Pin #12 24 VAC Hot "R" Signal, Always Energized

Pin #13 X X

Pin #14 X X X X X

Pin #15 X X X X X X X X X

Pin #16 Not Used

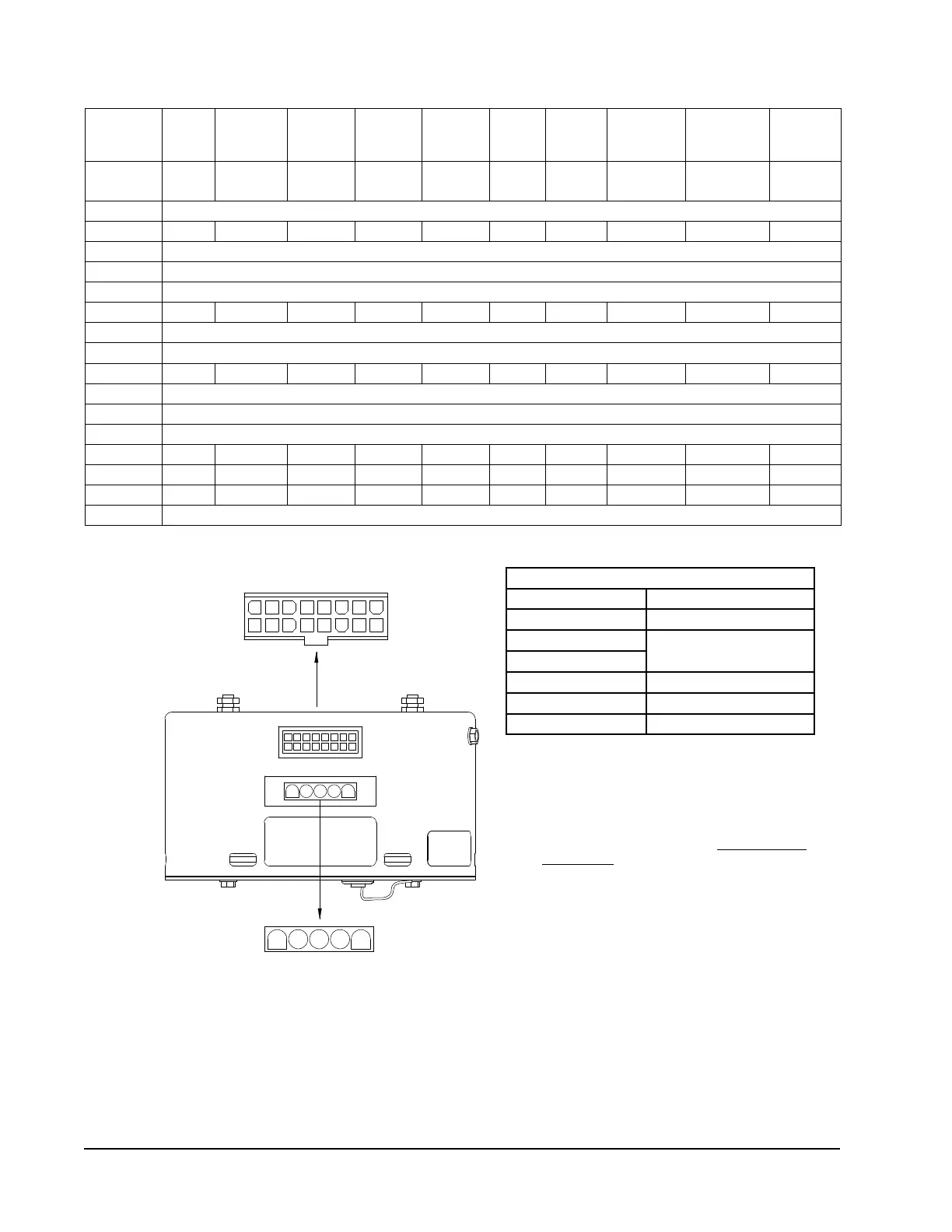

POWER CONNECTOR

PWB HEADER AMP 1-350945-0

PIN Description

1

Jumper Pin 1 to Pin 2 for

120VAC Line Input Only **

2

3 Chassis Ground

4 AC Line

5 AC Line

Troubleshooting ECM

™

Blower Motors

REFRIGERANT CHARGE

This unit was charged at the factory with the quantity

of refrigerant listed on the serial plate. AHRI capacity

and efficiency ratings were determined by testing with

this refrigerant charge quantity. The pressure tables

found on the following pages show nominal pressures

and temperatures for the units. Since many installa-

tion specific situations can affect the pressure read-

ings, this information should only be used by certified

technicians as a guide for evaluating proper system

performance. They shall not be used to adjust charge.

If charge is in doubt, reclaim, evacuate and recharge

the unit to the serial plate charge.

10

1 2 3 4 5 6 7 8

1615141312119

3 51 2 4

MIS-2839

FIGURE 39

Control Connector Motor Half

* Suggested mating connector

Housing — AMP 350809-1

Contact — AMP 350537-1

** WARNING — Applying 240VAC line input with

PIN 1 to PIN 2 jumper in place will permanently

damage unit!

Power Connector

Motor Half

Loading...

Loading...