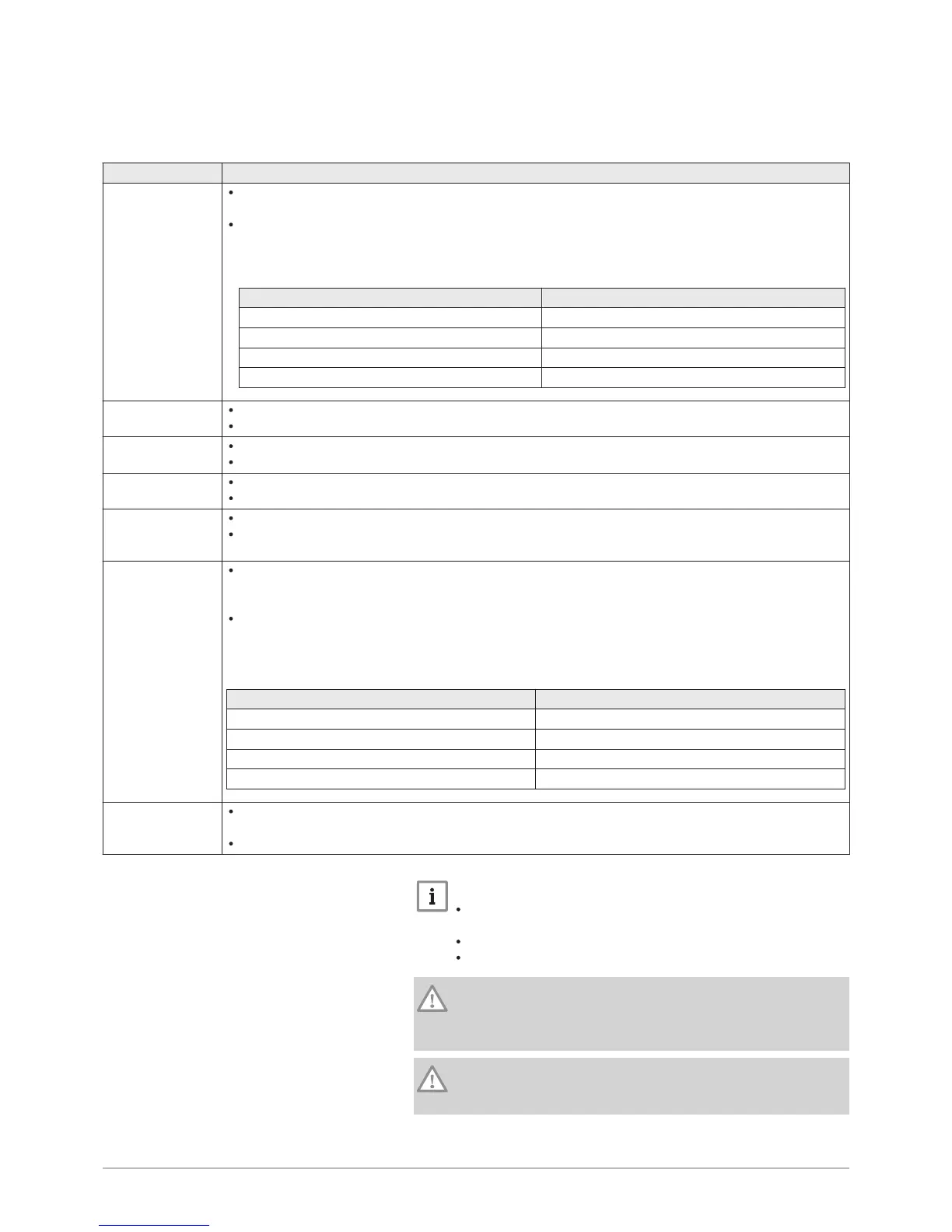

The pipes must deliver a maximum pressure drop in compliance with the

values given in the table below.

Tab.17 Configurations and recommendations for the flue system

Configuration Description

B

23

– B

23P

Connection to a chimney using a connection kit (single pipe in a flue, combustion air taken from the boil

er room).

The maximum pressure drop in the pipes ΔP must not exceed the values given in the table below. The

pipes must be certified for this type of use and for a temperature in excess of 100°C.

Tab.18

Model Maximum pressure drop ΔP (Pa)

POWER HT+ 1.130 200

POWER HT+ 1.150 200

POWER HT+ 1.200 200

POWER HT+ 1.250 200

C

13

Air/flue gas connection using concentric pipes to a horizontal terminal (so-called forced flue).

The terminal parts of the singled-up discharge pipe must be scheduled inside a 50 cm square.

C

33

Air/flue gas connection using concentric pipes to a vertical terminal (roof outlet).

The terminal parts of the singled-up discharge pipe must be scheduled inside a 50 cm square.

C

43

Air/flue gas connection to a collective flue for sealed boilers.

The chimney or flue gas pipe must be suitable for such use.

C

53

Separate air/flue gas connection using a bi-flow adapter.

The terminal parts of combustion air intake and combustion product discharge pipes must not be plan

ned on opposite walls of the building.

C

63

The maximum pressure drop in the pipes ΔP must not exceed the values given in the table below. The

pipes must be certified for this type of use and for a temperature of more than 100 °C. The terminal part

of the flue gas pipe must be certified as complying with the EN 1856-1 Standard.

If installing discharge and intake pipes not supplied by Baxi, these must be certified for the type of use

scheduled and present a maximum pressure drop in line with the values given in the table below.

Tab.19

Model Maximum pressure drop ΔP (Pa)

POWER HT+ 1.130 170

POWER HT+ 1.150 280

POWER HT+ 1.200 230

POWER HT+ 1.250 230

C

83

Flue gas connection to a collective flue for sealed boilers. The air supply is individual via a terminal

coming from outside the building.

The chimney or flue gas pipe must be suitable for such use.

Important

Only original components are authorised for connection to the

boiler and for the terminal.

The clear section must comply with the standard.

The chimney must be swept before installing the discharge flue.

Caution

Ensure that the flue gas discharge pipes are securely attached to

the wall with suitable retaining flanges to prevent any damage and

guarantee the tightness of every gasket in the circuit.

Caution

The minimum gradient of the condensates discharge pipe from the

boiler to the waste water discharge must be 1 cm per linear metre.

7 Installation

Loading...

Loading...