FBXXX Field Temperature Block

70

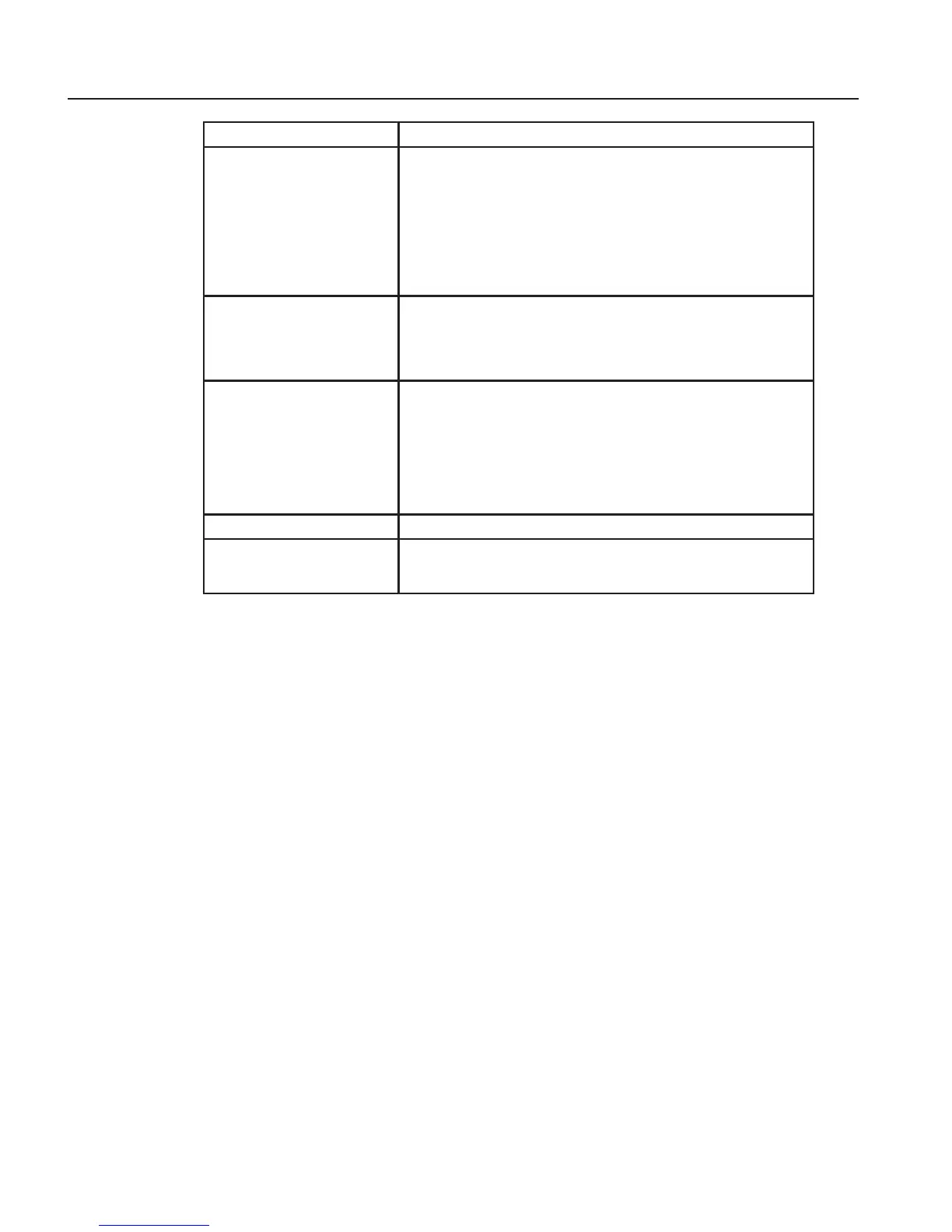

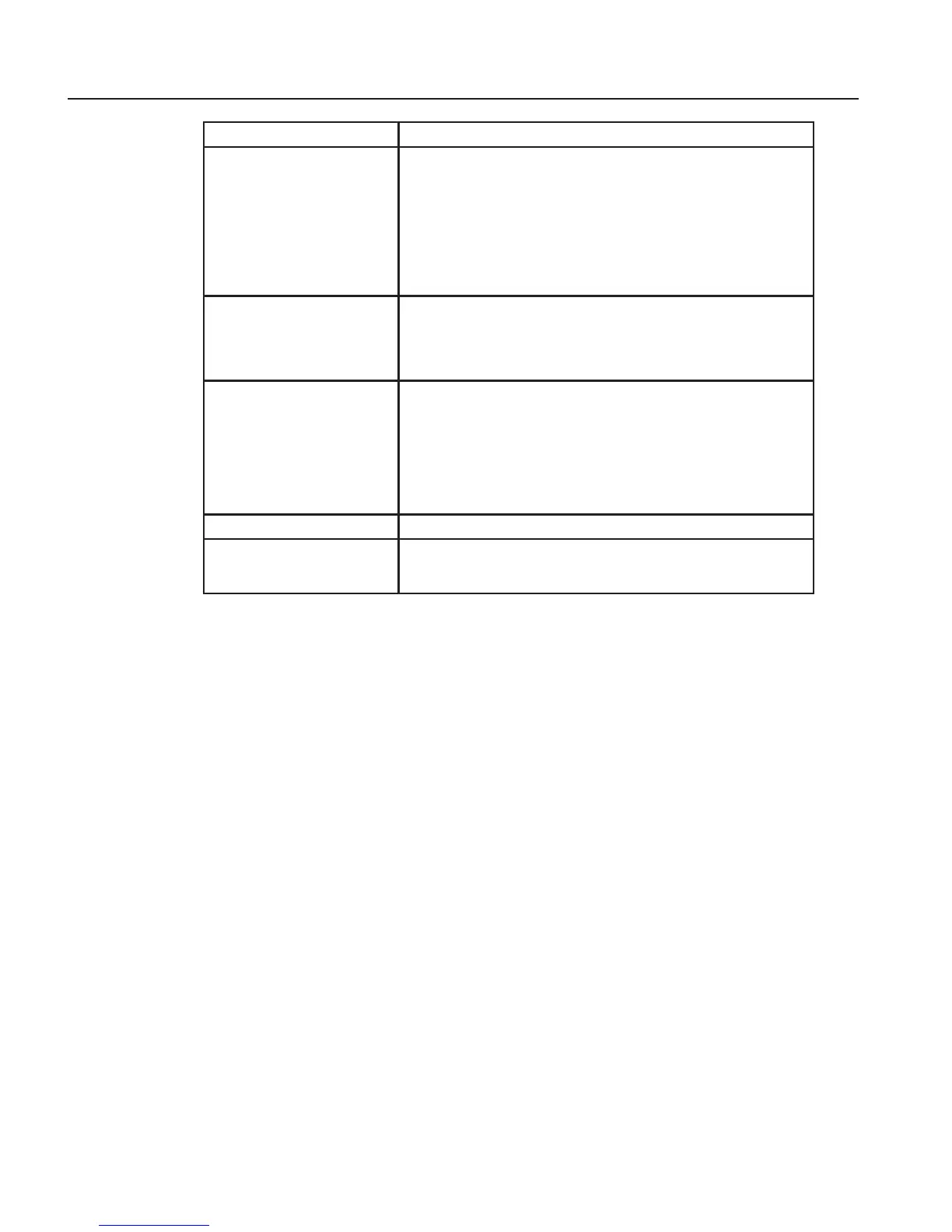

Problem Causes and Solutions

Temperature readout is not

the actual temperature of the

well OR Incorrect temperature

reading

Operating Parameters. Insure that all operating parameters for the

Temperature Block, reference thermometer, and/or probe parameters

match the Report of Certication that was sent with the instrument

and/or probe.

Electrical Interference. Look for sources of electrical interference,

such as motors, welders, generating equipment nearby, or ground

loops. Try shielding wires, removing ground loops, or changing

location.

(FB150) Probes stuck in the

well at low temperatures

Moisture. If the Temperature Block has been used at low

temperatures for extended periods of time, moisture may have built

up in the well forming ice at low temperatures. Set the temperature

high enough to melt ice to remove probes. Set the set-point to

+100°C and allow the moisture to evaporate out of the system.

(FB150) Insert stuck in well If maintenance has not been performed on the insert as described

in the Maintenance Section and the insert cleaned periodically, hard

water build-up on the insert may cause it to stick.

Have the unit in a cold environment – less 21°C. Set the unit to

100°C. While the unit is heating, at approximately 50°C to 70°C, pull

on the insert.

If this does not remove the insert, contact an Authorized Service

Center.

-R Model Only

The Ref Probe shows an

abnormal temperature or “……”

Check the Probe type setting in the Reference Probe Setup menu

is correct. Check all associated parameters. Check that the 4 probe

wires are connected and not shorted inside of the connector.

Loading...

Loading...