What to do if Beisler Sewing Machine shows error 25 scissor not down?

- AAshley SimmonsSep 16, 2025

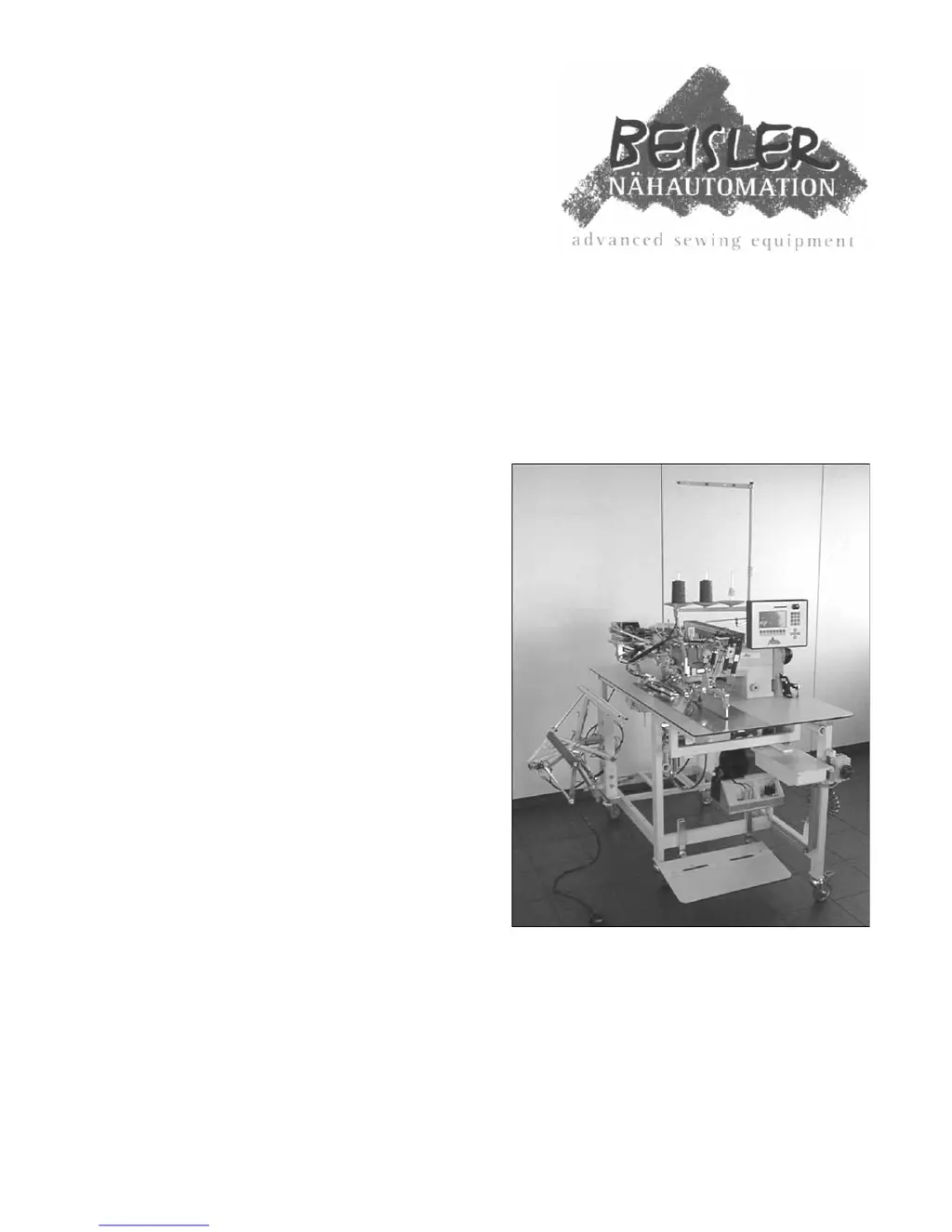

If your Beisler Sewing Machine displays Error 25, it means the scissor couldn’t reach the cutting position within the error time. Check the cylinder, gauges Y21 and Y22, and termination switch ES15.