US-EN Installation and operation instructions

DRYPOINT

®

M intelligence 11

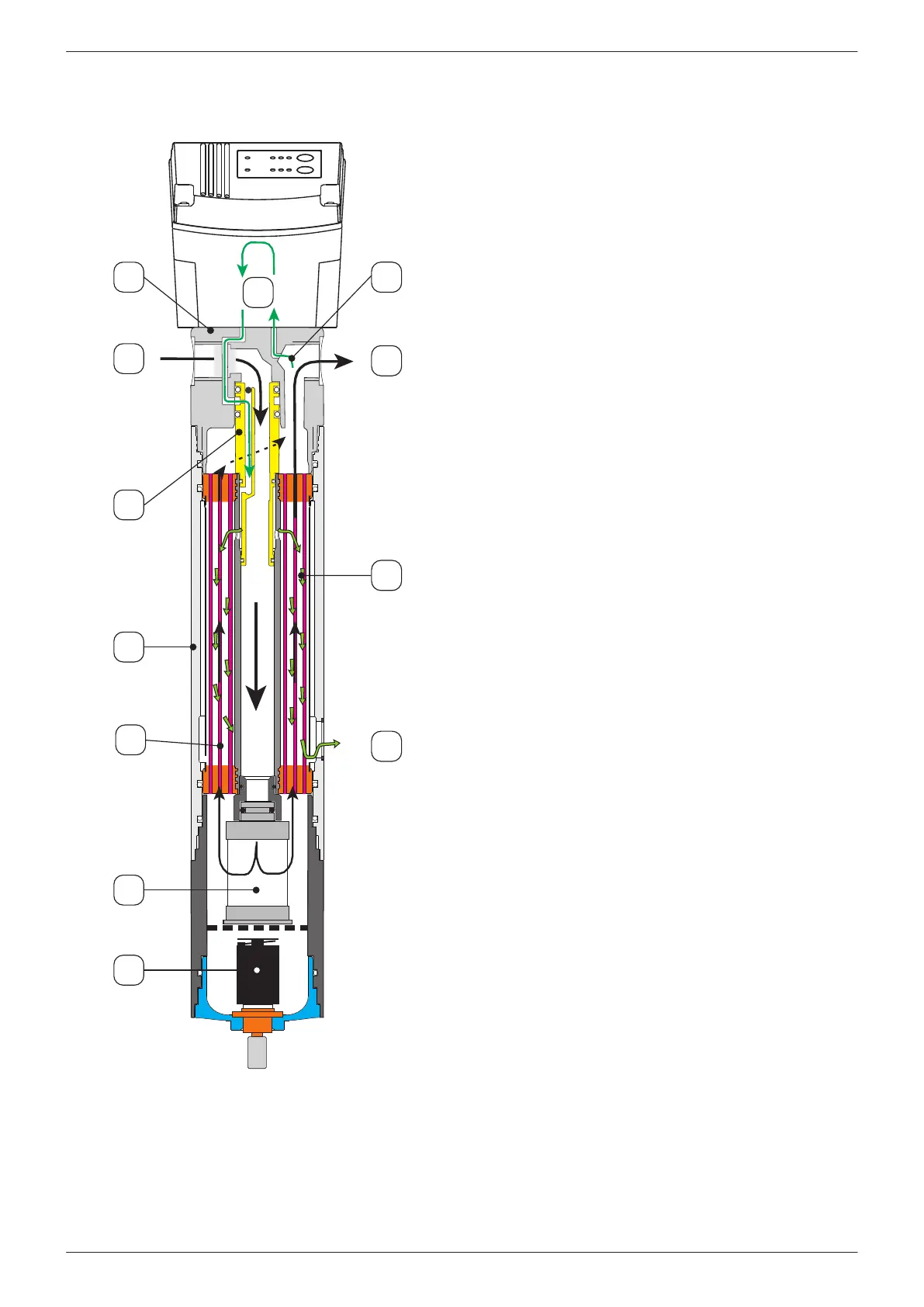

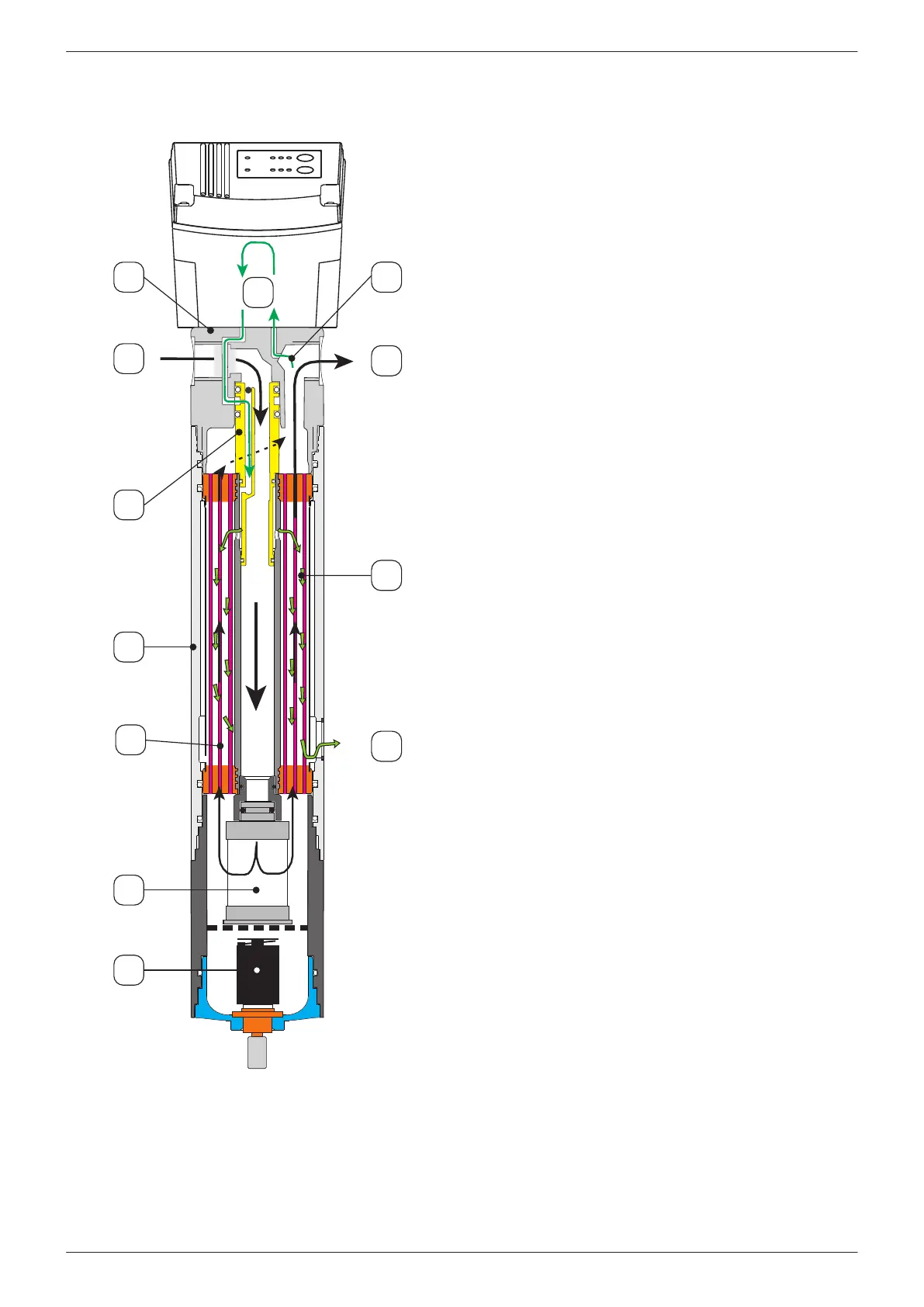

2.3.1. Operating principle

Humid compressed air (2) enters the unit through the

housing head (1) and ows downwards through the core tube

of the membrane element (5). A nanolter is located at the

outlet of the core pipe

(6) xated, which removes residual aerosols and particles

from the compressed air. The resulting condensate is drained

o at the base and is discharged by the oat drain (7).

At the nanolter element, the compressed air is directed in

the opposite direction and the humid compressed air ows

through the membranes of the internal membrane element.

A partial ow (9) of the compressed air

will be branched after the membrane element and bypasses

the sensor continuously in the purge air control. Based on the

sensor signals, the purge air control opens the purge air inlet

to the membrane dryer, if purging is required. As a result, the

purge air pressure drops to the atmospheric pressure and

is much dryer than the compressed air, as the moisture is

distributed to a much larger volume.

The very dry purge air (10) will be routed through the purge

air channel in the head and purge air nozzle (3) to the outside

of the membranes (11) and will be evenly distributed due to

the orderly position of the membranes. This means that there

are two air ows through the membrane element (5) with

dierent humidity content in the counter ow.

Humid compressed air at the inside and dry purge air at the

outside.

Due to the humidity gradient, water diuses from the

compressed air to the purge air. The humid purge air (12) is

then released to the ambient air. The dried compressed air (8)

leaves the membrane dryer.

Loading...

Loading...