GrandPrix (GP-7 Series) Two-Post Lifts 20 P/N 5900209 — August 2018 — Rev. C2

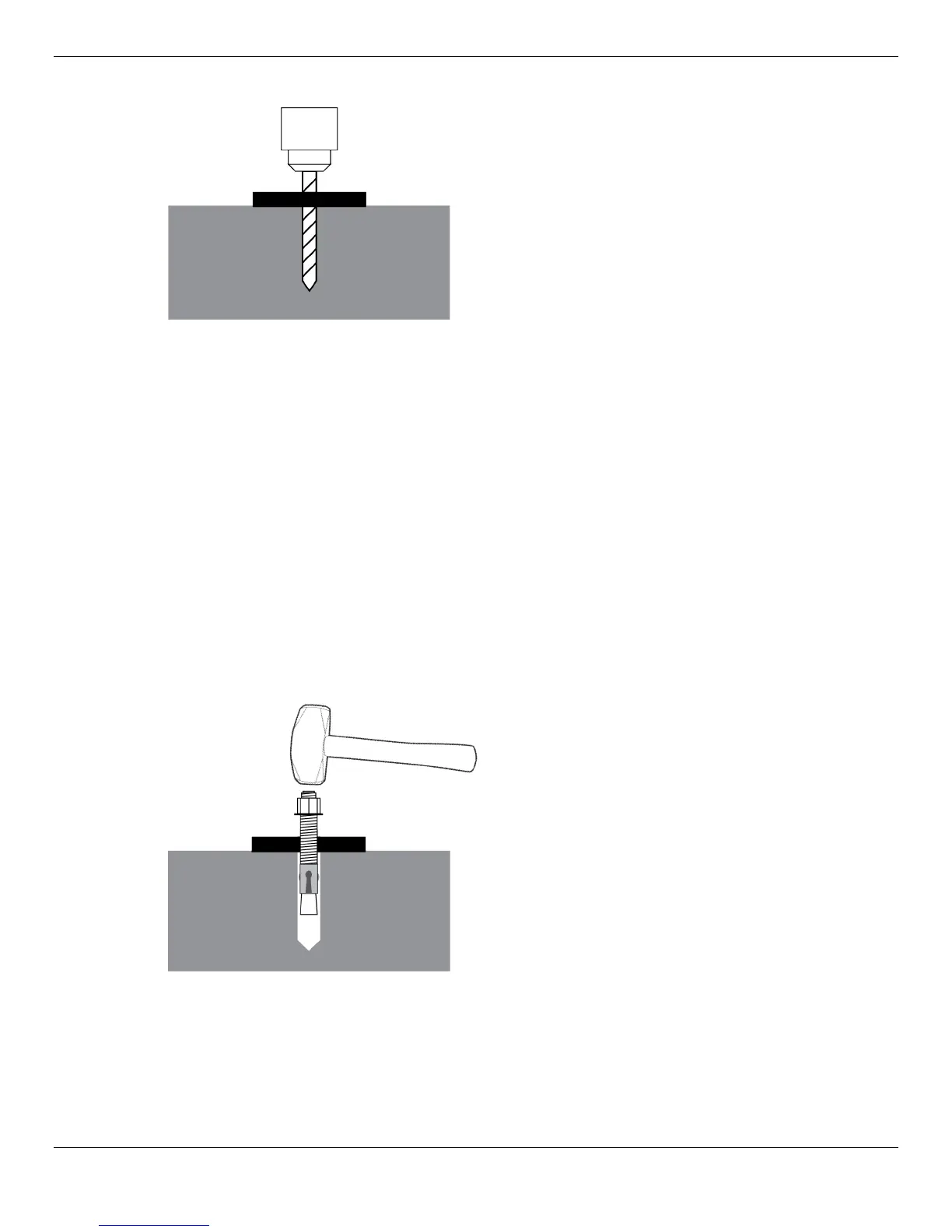

4. Using the Base Plates as guides, drill the holes for the Anchor Bolts.

Go in straight; do not let the drill wobble.

Use a carbide bit (conforming to ANSI B212.15-1994).

The diameter of the drill bit must be the same as the diameter of the Anchor Bolt. So if you are

using a ¾ inch diameter Anchor Bolt, for example, use a ¾ inch diameter drill bit.

5. Vacuum each hole clean.

BendPak recommends using a vacuum to get the hole very clean. You can also use a wire brush,

hand pump, or compressed air; just

make sure to thoroughly clean each hole

.

Do

not

ream the hole. Do

not

make the hole any wider than the drill bit made it.

Important: The holding strength of an Anchor Bolt is partially based on the how cleanly the

Expansion Sleeve presses against the Concrete. If the hole is dirty, the Expansion

Sleeve does not press as cleanly, which means less holding strength. If the hole is

too wide, the Expansion Sleeve does not press against the Concrete with as much

force, again resulting in less holding strength.

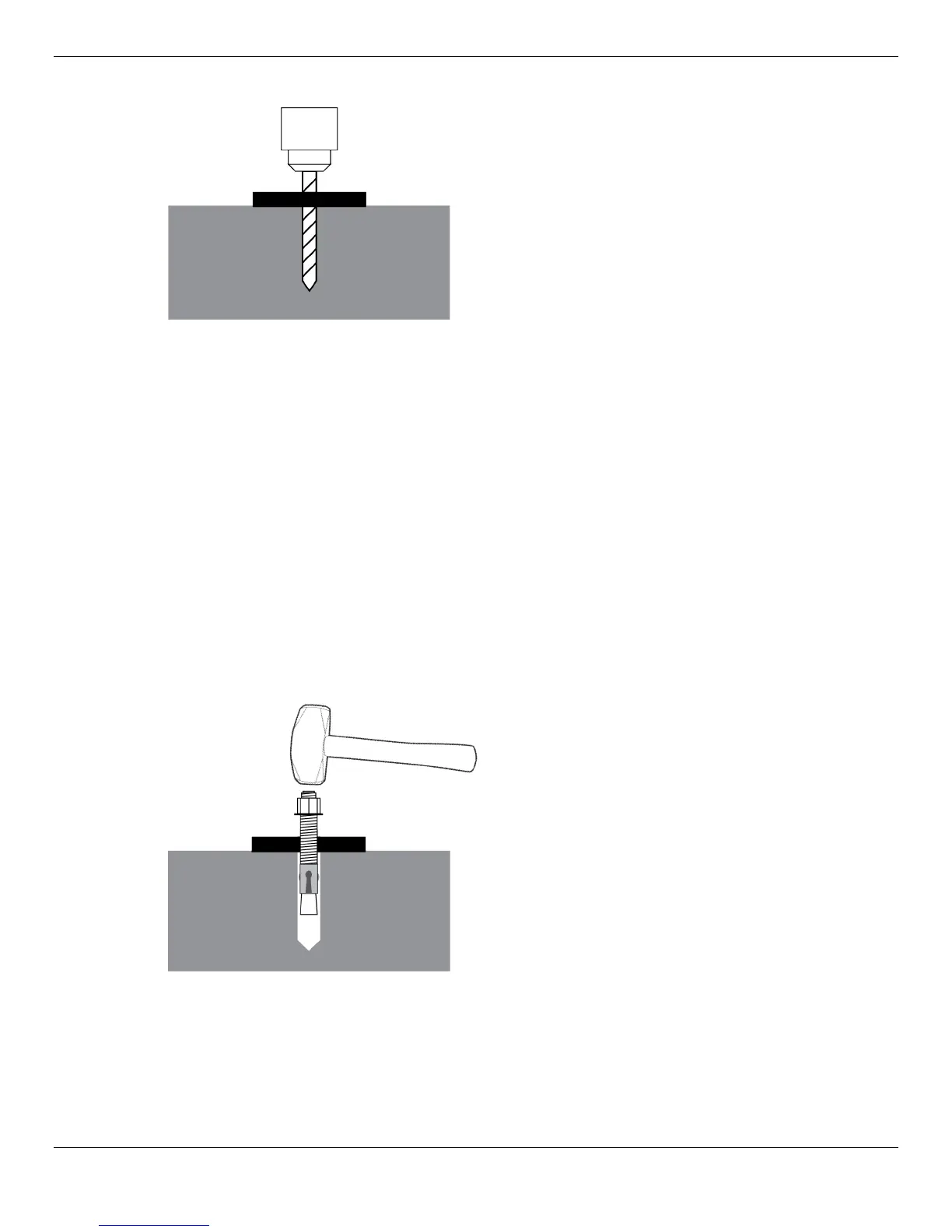

6. Make sure the Washer and Nut are in place, then insert the Anchor Bolt into the hole.

The Expansion Sleeve of the Anchor Bolt may prevent the Anchor Bolt from passing through the

hole in the Base Plate; this is normal. Use a hammer or mallet to get the Expansion Sleeve through

the Base Plate and into the hole.

Even using a hammer or mallet, the Anchor Bolt should only go into the hole part of the way; this is

normal. If the Anchor Bolt goes all the way in with little or no resistance, the hole is too wide.

Loading...

Loading...