30

POST-INSTALLATION CHECK-OFF

Columns Properly Shimmed And Stable

Anchor Bolts Tightened

Pivot / Sheave Pins Properly Attached

Carriage Stop bolts Torqued to 2-3 Ft. Lbs

Electric Power Supply Confirmed

Cables Adjusted Properly

Safety Locks Functioning Properly

Check For Hydraulic Leaks

Oil Level

Lubrication of Critical Components

Check For Overhead Obstructions

Lift Arms Level

All Screws, Bolts, and Pins Secured

Surrounding Area Clean

Operation, Maintenance and Safety Manuals

on Site.

.

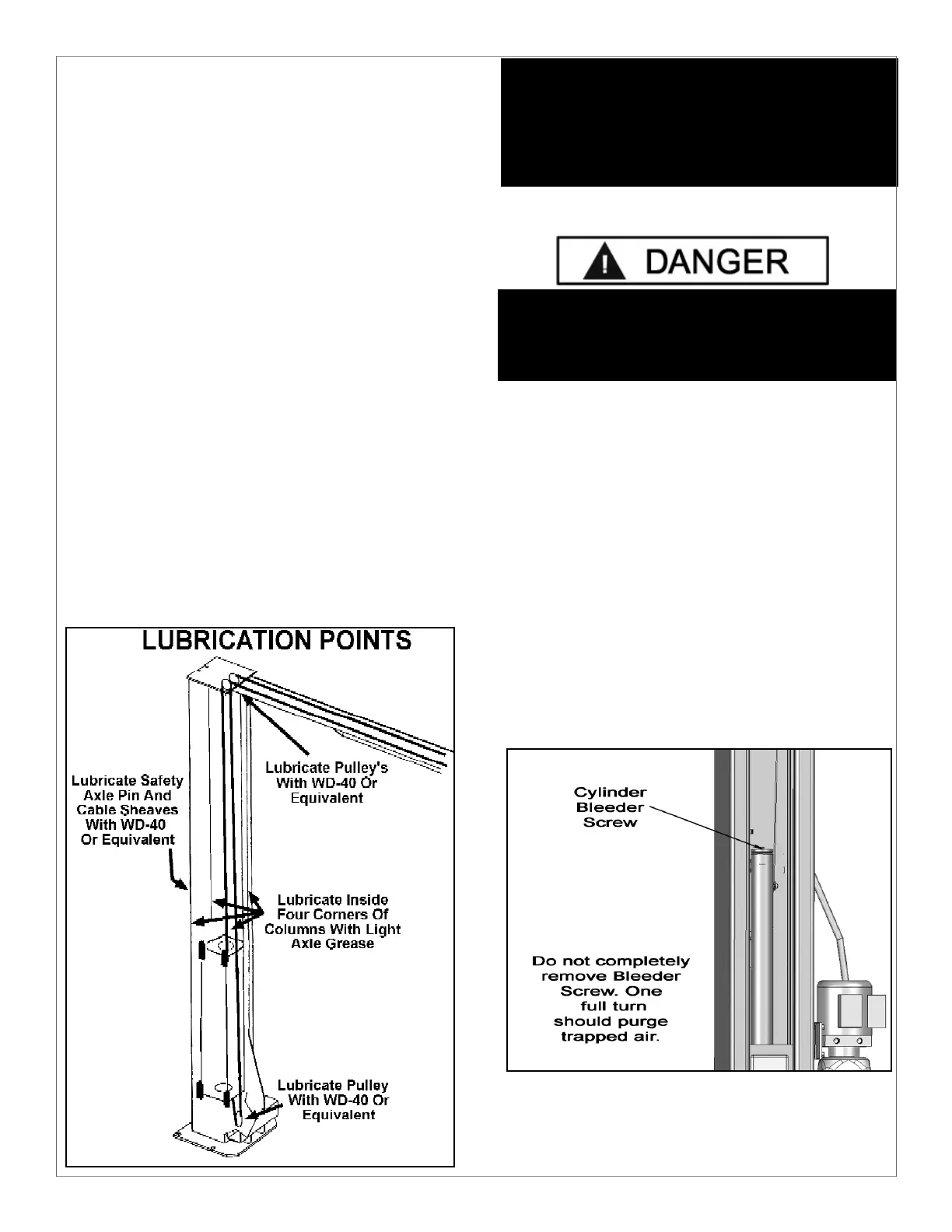

STEP 19

( Lubrication )

1. After installation and start up has been completed,

lubricate lift components as described below.

(See Fig. 19.1)

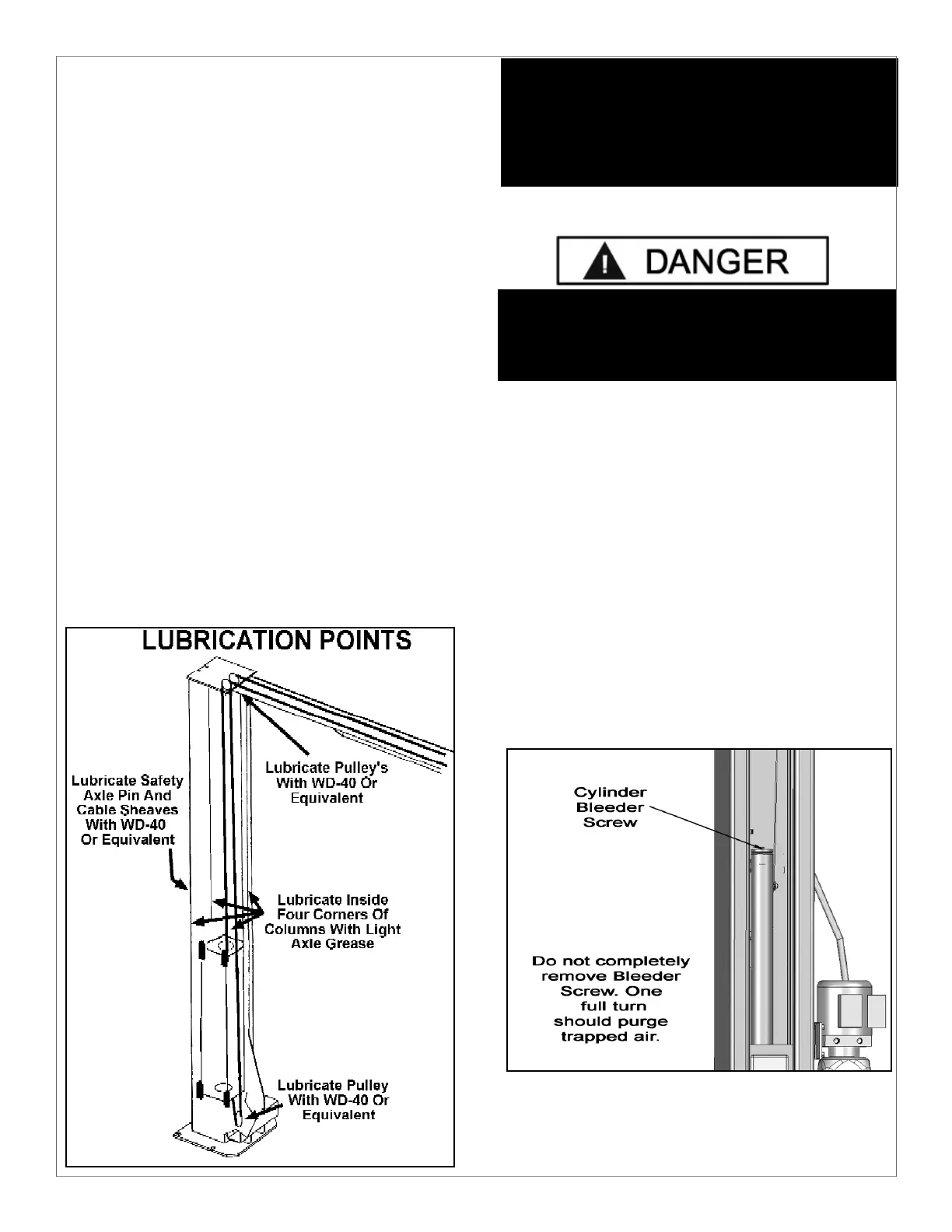

STEP 20

( Bleeding )

1. After electrical power is connected and oil reservoir is

full press button to raise lift.

2. Continue raising until lift Cylinders bottom out at full

height. DO NOT continue pressing button after lift reaches

full height. Damage to motor can occur if continued.

3. Lower the lift only HALF WAY by pressing the SAFETY

RELEASE handle inward then pressing in the DOWN

lever on power unit.

4. With the lift at half height, slowly loosen the BLEED

SCREWS located at the top of each Cylinder to bleed

trapped air. DO NOT completely remove bleed screws.

Retighten after trapped air has escaped. (See Fig. 20.1)

5. Lower the lift completely by pressing the SAFETY

RELEASE handle inward then pressing the DOWN lever

on Power Unit. Wait five minutes and repeat bleeding

process one additional time.

NOTE:

There will be initial stretching of the cables in the begin-

ning and/or with increased loads. Adjust the cables as

outlined above a week after first use, then every three

to six months thereafter depending on usage and/or to

compensate for stretch.

Fig. 19.1.

Fig. 20.1

DANGER!

THE LIFT WILL MOVE DOWN WHEN BLEEDING

MAKE SURE ALL EQUIPMENT,PERSONNEL ,HANDS

AND FEET ARE CLEAR BEFORE BLEEDING

Loading...

Loading...