33 Bentone BF1

General

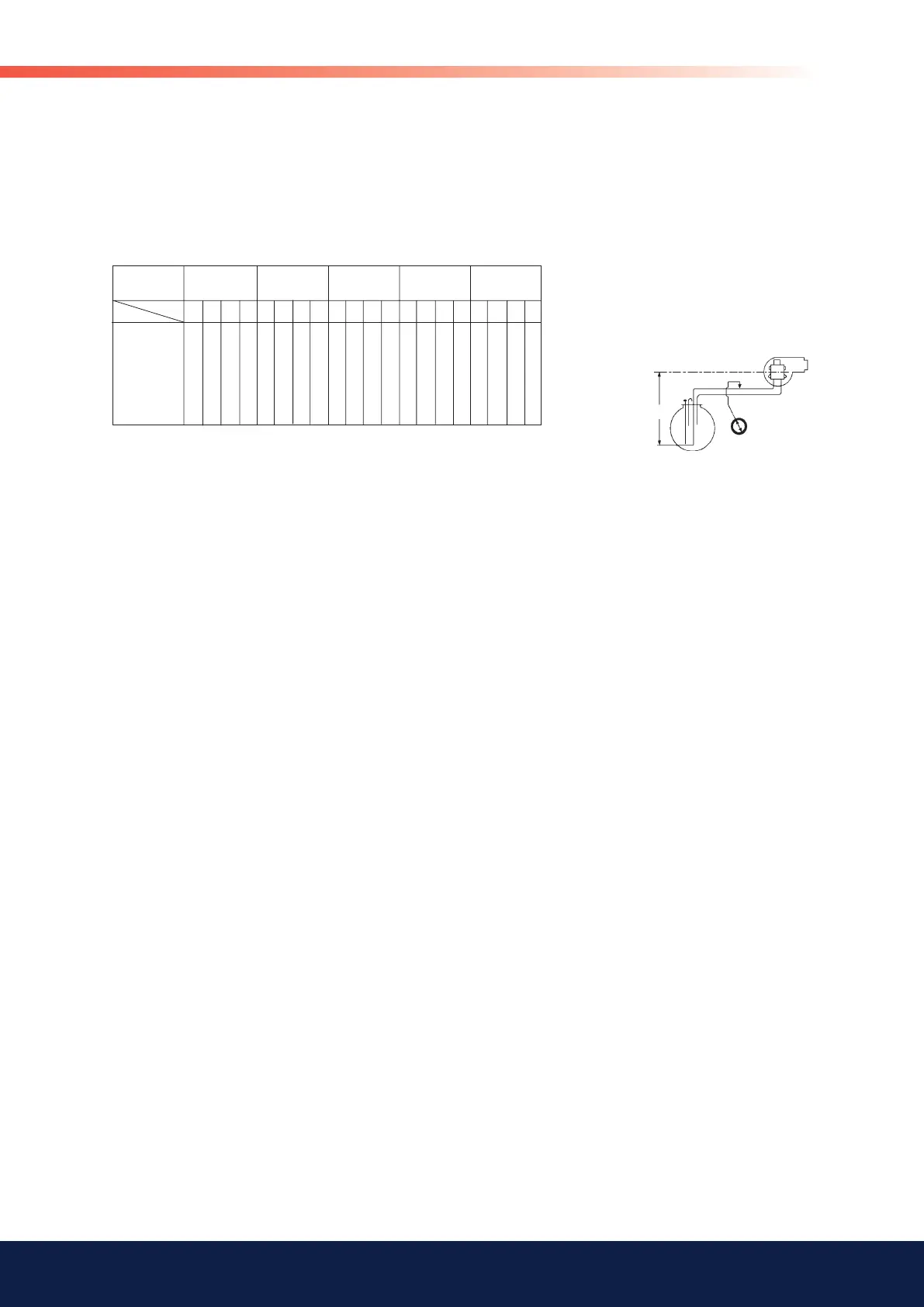

Two pipe lift system

Zweistranginstallation - Tank tiefer als Pumpe

Installation bitube en aspiration

Impianti bitubo in aspirazione

H

H max. = 4,5 m

d

6.1.1.2 Underlying tank

1-pipe system

With an underlying tank a 1-pipe-system is not recommended

Two-pipe system

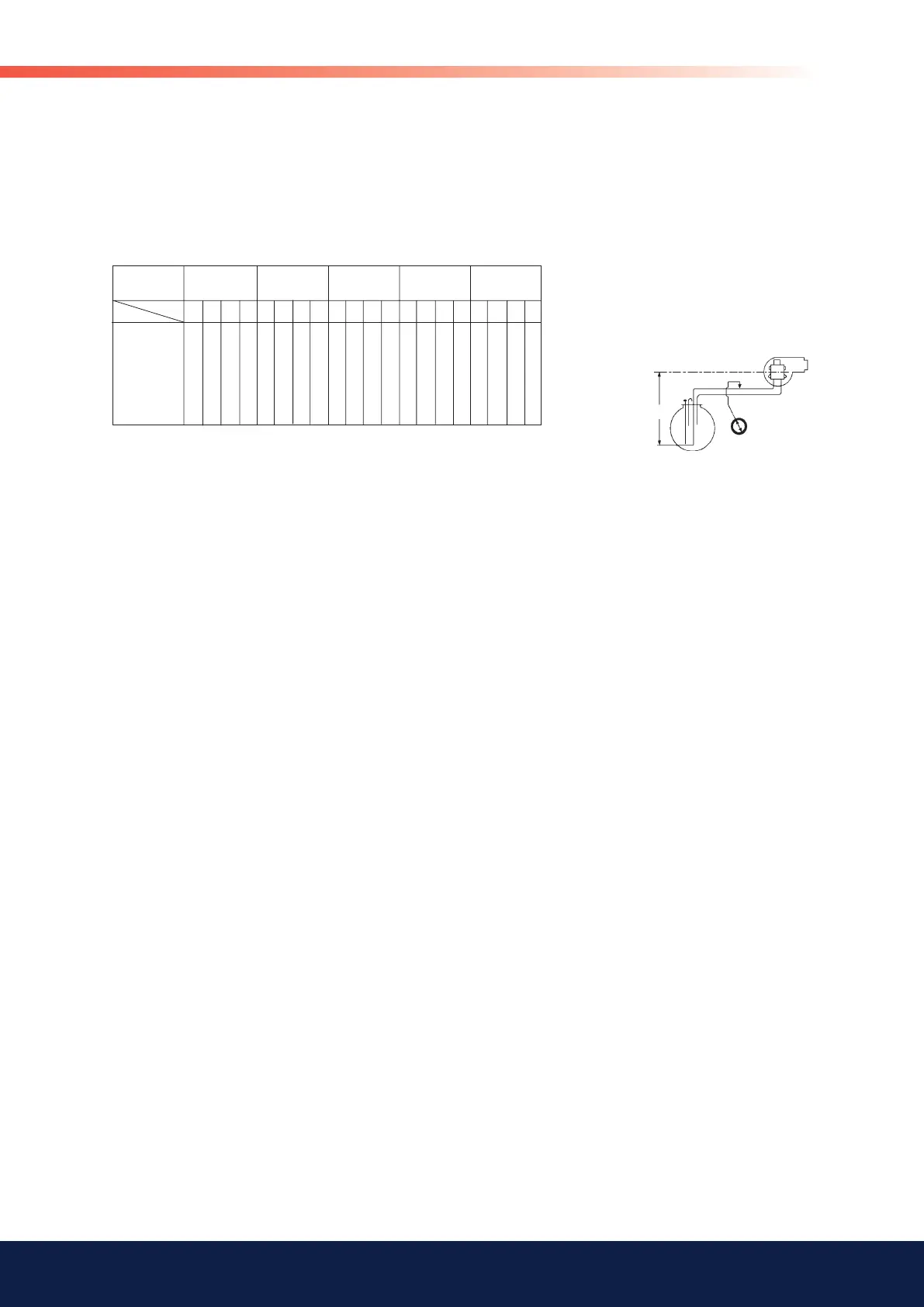

0 15 50 124 150

0,5 13 44 109 150

1 11 38 95 150

2 7 26 66 138

3 3 14 37 79

84 19

11 38 96 150 7 27 71 150 20 54 116 150 16 46 100 150

9 33 84 150 6 24 62 132 17 48 103 150 14 40 88 150

8 29 73 150 4 20 54 115 15 41 89 150 12 34 76 144

5 19 51 107 2 13 37 80 9 28 61 116 7 23 52 100

10 28 60 6 20 44 4 14 33 65 11 28 55

5 14 9 6 14 4 11

d (mm)

35/45 55 65 75 95

60 77 102 130 150

Pump/Pumpe

Pompe/Pompa

Q** (l/h)

6 8 10 12 6 8 10 12 6 8 10 12 8 10 12 14 8 10 12 14

H (m)

The suction line tables consist of theoretically calculated values where the

pipe dimensions and oil velocity have been matched so that tur-bulences will

not occur. Such tur-bulences will result in increased pressure losses and in

acoustic noise in the pipe system. In addition to drawn copper piping a pipe

system usually comprises 4 elbows, a non-return valve, a cut-off valve and

an external oil filter.

The sum of these individual resi-stances is so insignificant that they can be

disregarded. The tables do not include any lengths exceeding 100 m as

experience shows that longer lengths are not needed.

The tables apply to a standard fuel oil of normal commercial quality accor-

ding to current standards. On commis- sioning with an empty tube system

the oil pump should not be run without oil for more than 5 min. (a condition is

that the pump is being lubricated during operation).

The tables state the total suction line length in metres at a nozzle capacity of

9,5 Gph. Max. permissible pressure at the suction and pressure side is 2,0

bar.

Loading...

Loading...