Alarms

Precellys

®

24

Page 27/35

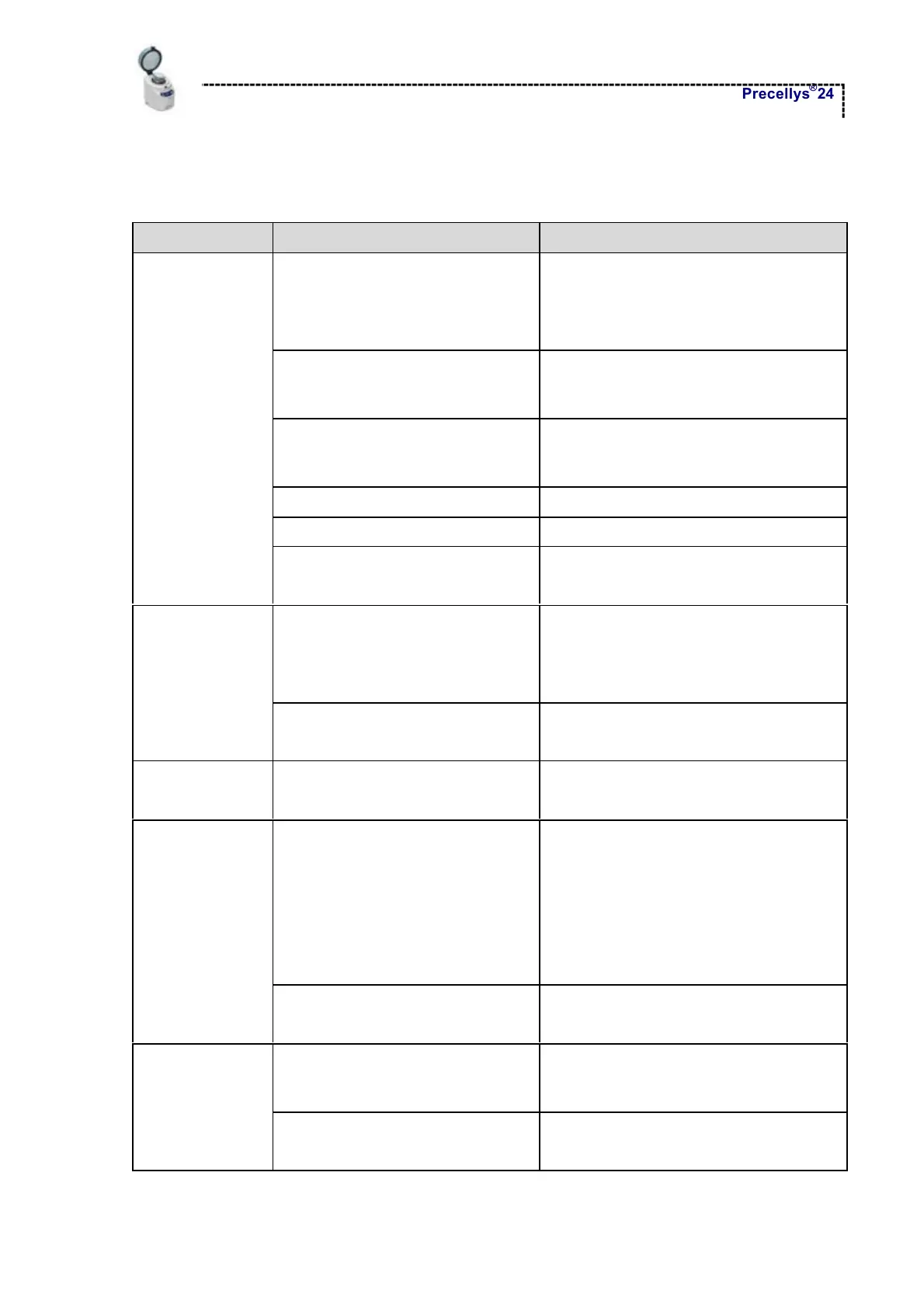

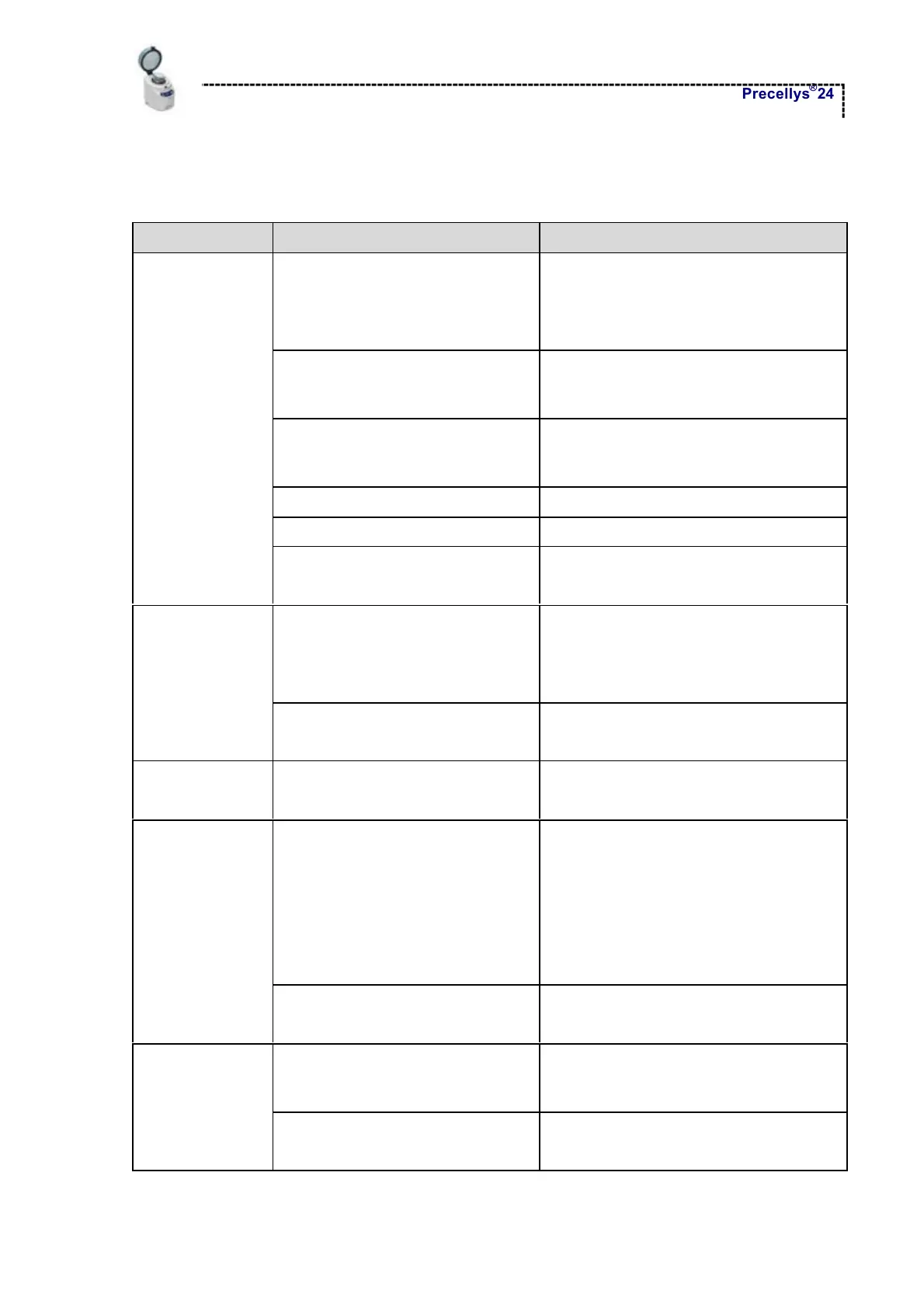

7.3 What to Do When an Alarm Message Occurs

Alarm message Possible cause Action(s)

Tubes (recommended by Bertin

Technologies, see § 2.5) are not

positioned properly.

1. Reposition the grinding tubes on the

holder.

2. Press in the middle of indented plate

during depression phase (cover open).

The indented plate is not positioned

properly.

Reposition the indented plate on the holder

and make sure the indented plate is placed

properly using the positioning guide.

The toric joint is not positioned

properly.

Reposition the toric joint on the holder and

make sure it is adjusted properly to the

holder’s groove.

The indented plate is damaged. Replace indented plate.

The toric joint is damaged. Replace toric joint.

Pressure alarm

The vacuum is not working properly.

1. Turn off the unit.

2. Contact technical assistance.

The cover is not locked properly.

1. Check that nothing prevents the cover

from closing.

2. Press cover and ensure the handle is

locked properly.

Top alarm

Detection system is faulty.

1. Turn off the unit.

2. Contact technical assistance.

Err speed sensor

Speed regulation or detection system

is faulty.

1. Turn off the unit.

2. Contact technical assistance.

Engine temperature has reached the

safety limit.

1. Leave the unit on so that the motor

ventilation can run.

2. Ensure air openings and the cooling

fan are clear.

3. After 30 minutes of cooling, if the

alarm is still on, contact technical

assistance.

Over temp wait !

Detection system is faulty.

1. Turn off the unit.

2. Contact technical assistance.

Power supply is not suitable.

Check the voltage on the back of the unit

matches that delivered by the main power

supply.

Err power supply

No synchronization between unit and

power supply.

1. Turn off the unit.

2. Contact technical assistance.

Loading...

Loading...