16

Rev 9 2022

Maintenance & Repair Feed Wheel/

Blade Height Adjustment

When a dispense key is pressed the tape cuer blade and the lower feed wheel li up. The machine has an adjustment

set screw that sets the height of the blade and lower feed wheel. The adjustment sets the amount of pinch force

between the upper and lower feed wheels. If the feed wheel does not grip the tape suciently, the tape can slip. When

the tape slips an inaccurate measurement of the tape length occurs, resulng in a shorter than normal tape piece. If

short or errac tape lengths occur, the adjustment described below may need to be performed to correct the problem.

Tools needed

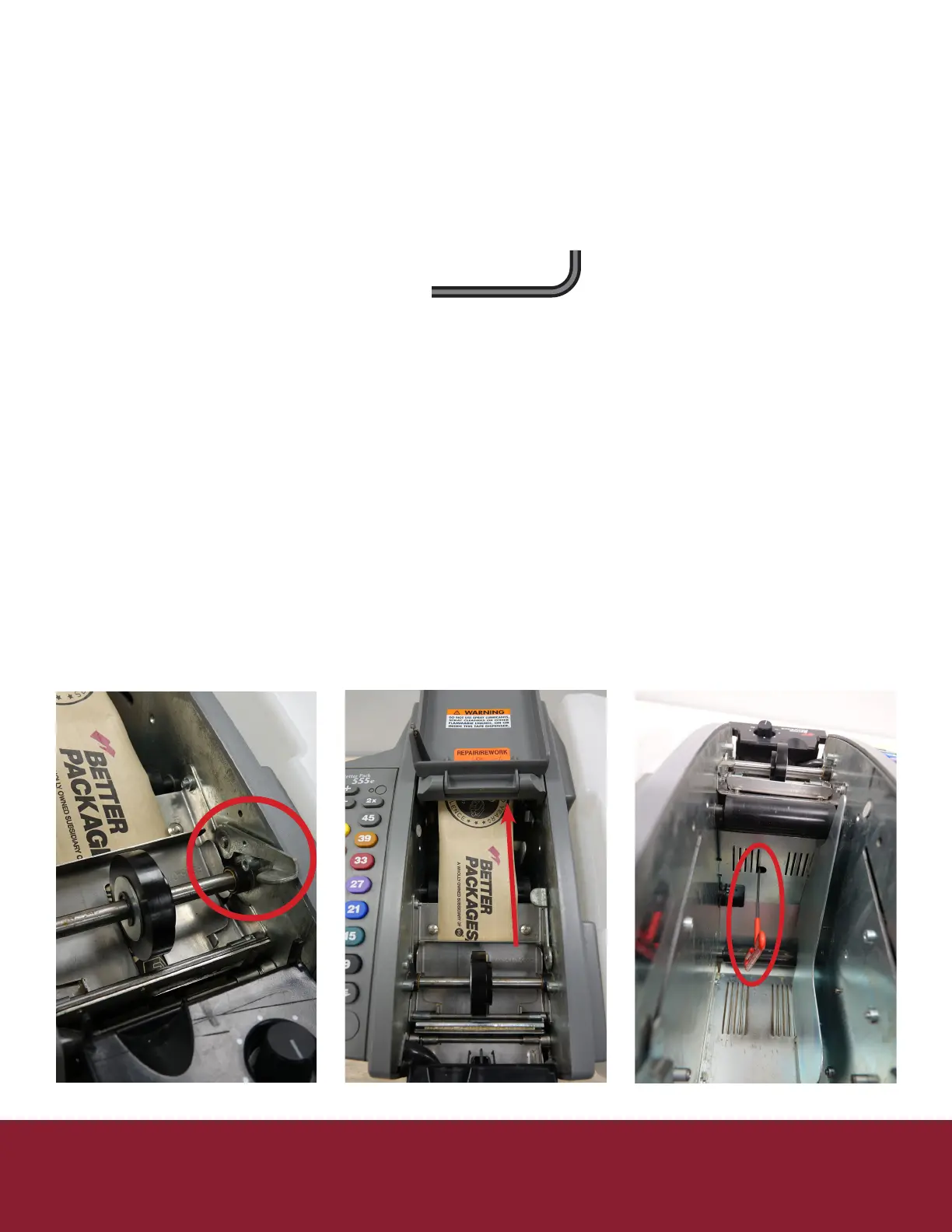

• 3/32” Allen wrench 4” long at minimum

Procedure

1. Unplug the machine

2. Open the top cover

3. Install the tape fully

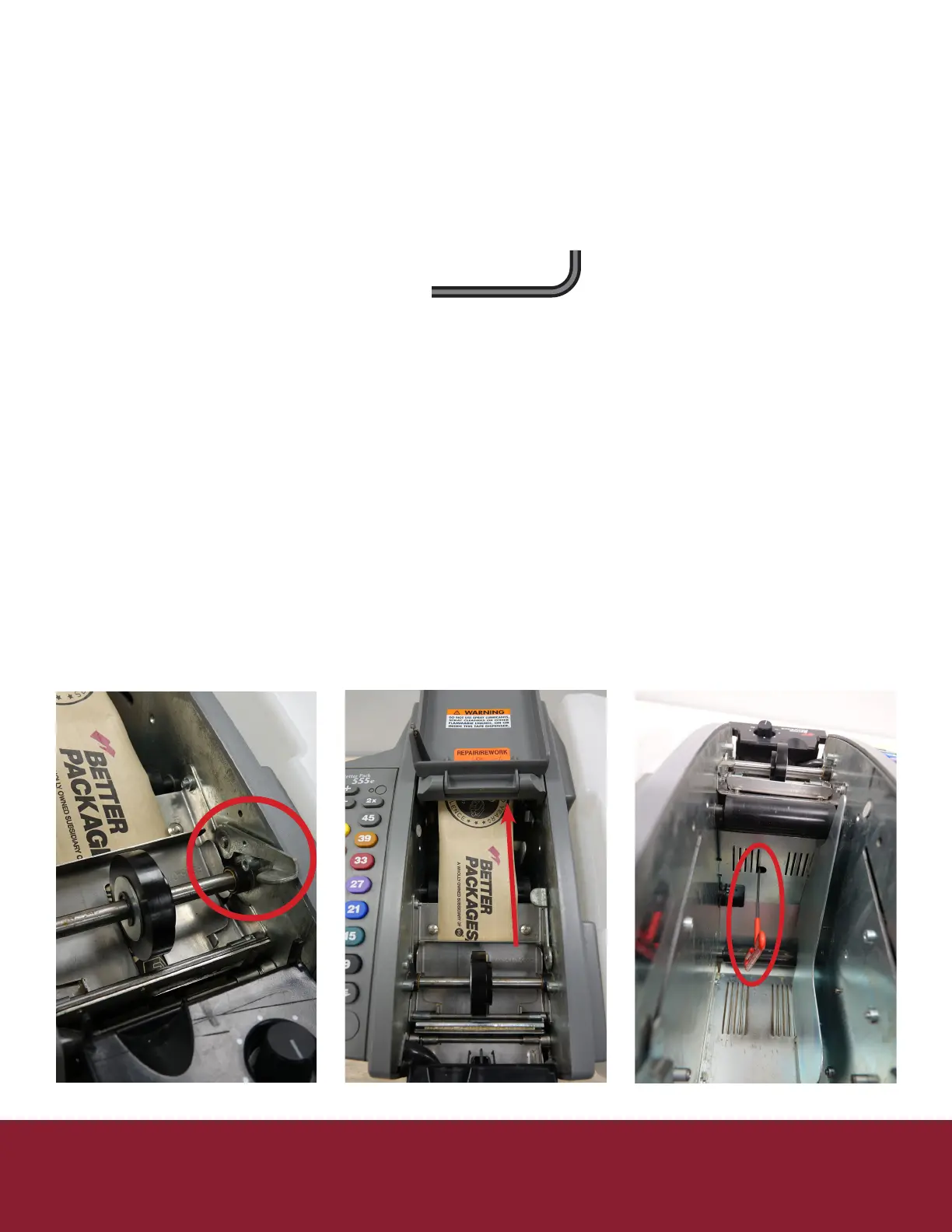

4. On the right side of the feed wheel, li up on the

lever (Figure 18-1)

5. Test the tension on the tape by pulling the tape

out from the back of the feed wheel see Figure

18-2 for direcon

a. If tape is removed easily with lile to no

resistance the feed wheel will need to be

ghtened (clockwise)

b. If tape is very dicult to remove the

feed wheel will need to be loosened

(counterclockwise)

6. Move the lever back to its home posion and

remove the tape from the machine

Figure 18-1 Figure 18-2 Figure 18-3

7. Turn the machine around so you are looking into

the cavity where the tape roll sits

8. Locate the feed wheel adjustment access hole, it

will be between the slide guides (Figure 18-3)

9. Use a 3/32” Allen wrench to make the needed

adjustments from step 4

a. Tighten or loosen in half turn

increments

10. Insert a strip of tape under the feed wheel and

li up on the lever

11. Pull the tape out from under the feed wheel.

b. Proper tension is achieved when the tape is

pulled taught and can be removed with a fair

amount of resistance

a. If this is not how it feels repeat steps

8 through 10 unl proper tension is

achieved

Loading...

Loading...