Rev 9 2022

21

Maintenance & Repair Blade Oiler

Replacing the blade oiler is considered part of standard maintenance. Typically this is done at the same me as

replacing the feed wheel and/or the heater assembly.

Part Numbers

• SA10XXK – Felt and Bracket Kit

Tools Needed

• Philips head screwdriver

• Needle nose pliers

Procedure

1. Unplug Machine

2. Remove the water bole, and tank assembly

3. Remove right side cover (5 Philips screws)

4. Remove le side cover (5 Philips screws) be

careful as the ribbons connecng the keypad can

be ripped easily.

5. Unplug keypad ribbons from controller board

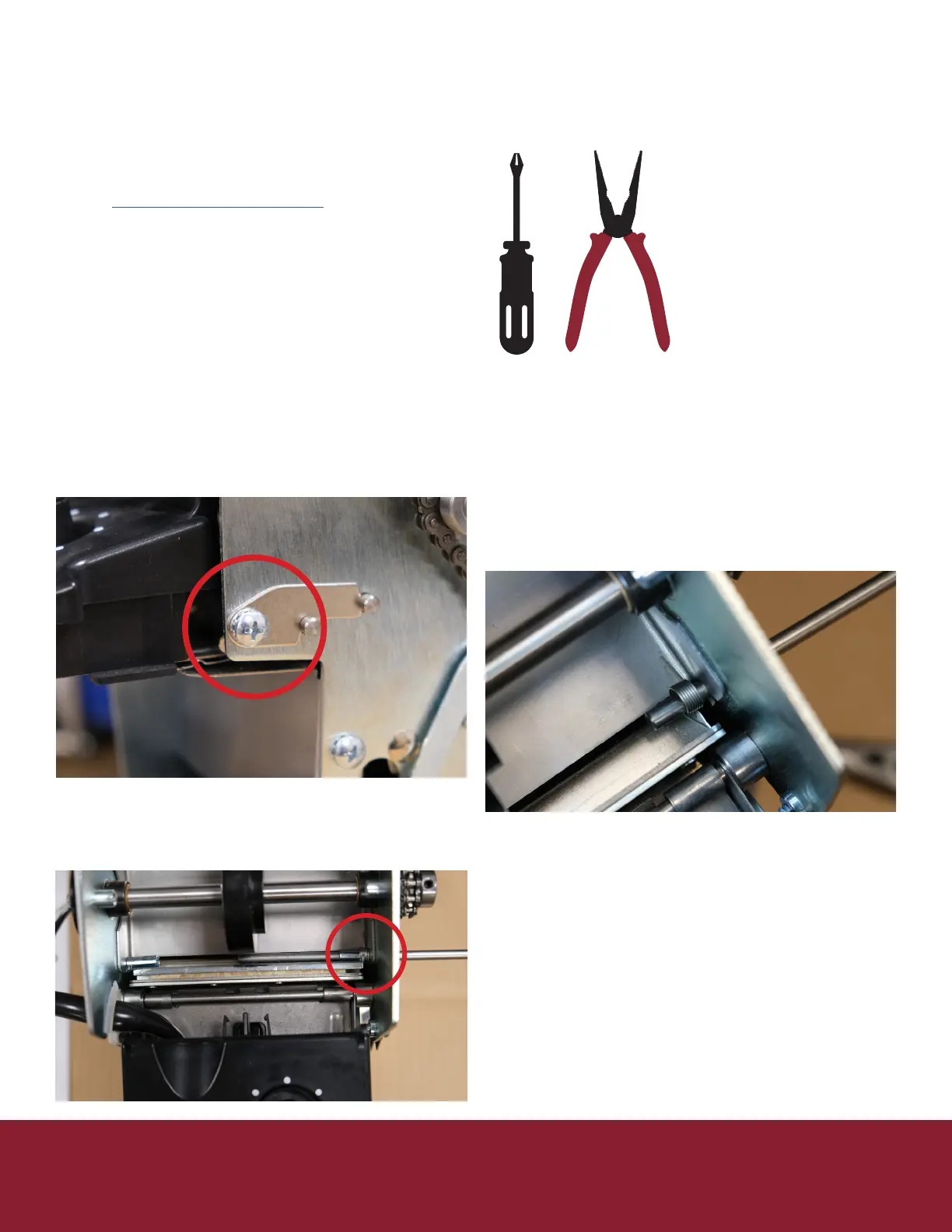

6. Loosen screw on the upper right side of frame

holding the retainer bracket

7. Li the retainer bracket

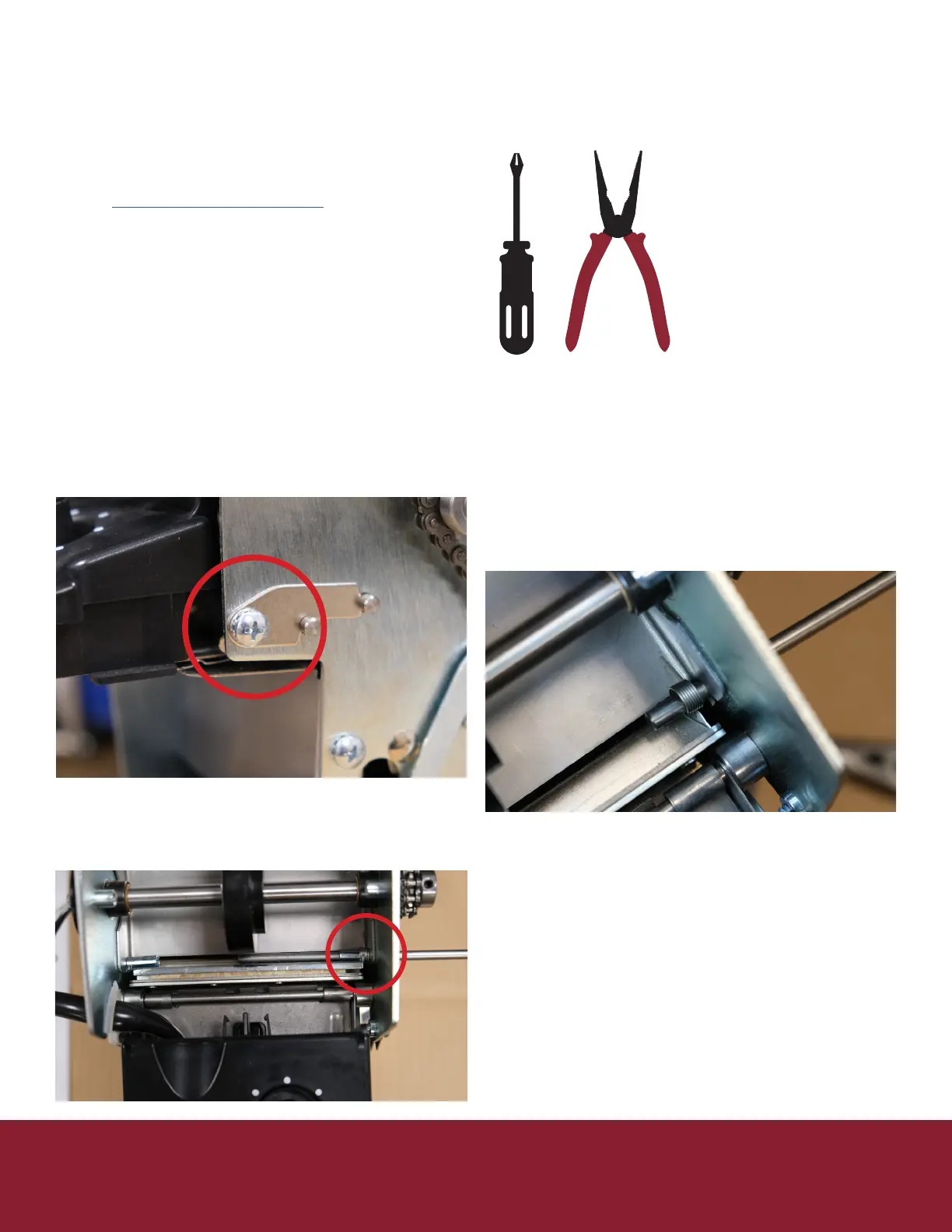

8. Remove the 2nd sha that holds the oiler

a. Use cauon as there is a spring under

tension

9. To install the new one, put the sha in from the

le side. As the sha is being inserted place the

new oiler in and be sure that the sha is going

through the oiler

10. Do not put sha all the way through. Place the

oiler spring at the right side holding it with a pair

of needle nose pliers.

11. The spring has to lay at on the lower tape plate.

Then you can get the sha to go through the

spring.

12. Now take the upper part of the spring that is

being held with the pliers and bring it to the

le of the oiler bracket where the bracket has a

bend on it. Let the spring go.

13. Replace the retainer bracket

14. Tighten the retainer screw locking the bracket

into place

15. Replace the right cover (5 Philips screws)

16. On le cover plug keypad ribbons back into

controller board

a. Be sure not to miss any pins as this will eect

the length selected

17. Reinstall le cover be sure not to pinch or drive a

screw through the keypad ribbons.

18. Replace water tank, brushes, and water bole

Loading...

Loading...