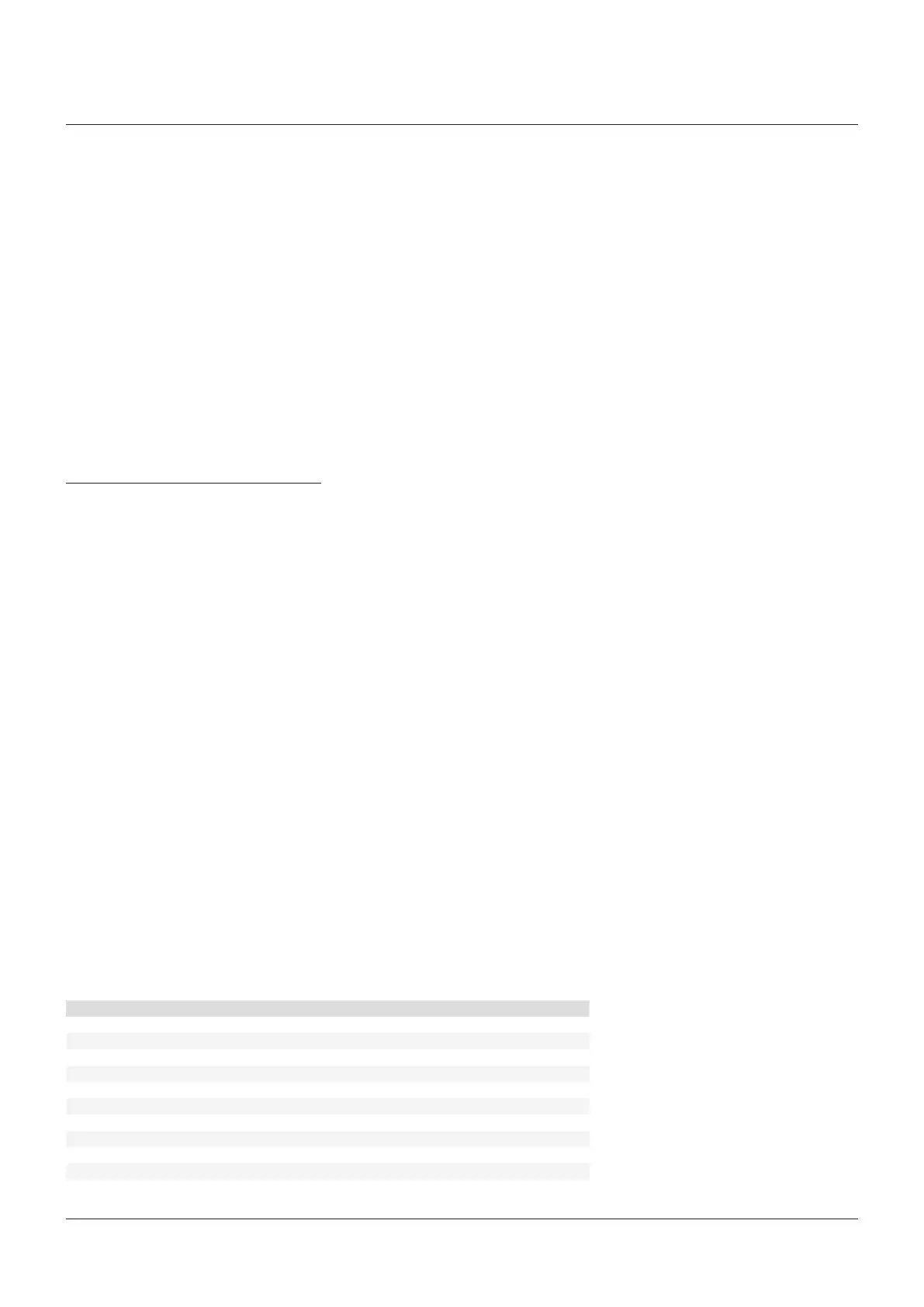

5

M6 8

M8 20

M10 40

M12 70

M14 110

M16 160

M20 320

M22 420

M24 550

M27 800

M30 1100

BIFFI FAIL SAFE ELECTRIC ACTUATORS, MODEL EFS2000V4

InstructIon and operatIng Manual

4 ASSEMBLING THE ACTUATOR ONTO THE

VALVE

The actuator is provided with an output flange

(or a spool piece and a stem extension) as

coupling to the valve. The assembly position of

the actuator, with reference to the valve, must

comply with the plant requirements (spring

cartridge axis parallel or perpendicular to the

pipeline axis).

4.1 Actuator supplied with insert already

machined

To assemble the actuator onto the valve

proceed as follows:

• Check that the coupling dimensions of the

valve flange and stem, or of the relevant

extension, meet the actuator coupling

dimensions.

• Arrange the valve in the position related to

the actuator spring operation.

• Lubricate the valve stem with oil or grease

in order to make the assembly easier: be

careful not to contaminate with lubricant the

flange surfaces with have to be connected to

transmit the actuator torque.

• Clean the valve flange and remove anything

that might prevent a perfect adherence to

the actuator flange and especially all traces

of grease, since the torque is transmitted by

friction.

Thread size Recommended tightening torque (Nm)

• Assemble the stem extension onto the valve

stem.

• Bring the actuator to the position caused by

the spring operation.

• Connect a sling to the support points of

the actuator and lift it: make sure the sling

is suitable for the actuator weight. When

possible, it is easier to assemble the actuator

to the valve if the valve stem is in the vertical

position. In this case the actuator must

be lifted while keeping the flange in the

horizontal position.

• Clean the actuator flange and remove

anything that might prevent a perfect

adherence to the valve flange and especially

all traces of grease.

• Lower the actuator onto the valve so that

the shaft output drive enters into the groove

of the stem extension. This connection

must take place without any force and only

by the weight of the actuator. When the

actuator output shaft and the valve stem

are connected, check the holes of the valve

flange. If they do not meet with the holes

of the spool piece flange or the stud bolts

screwed into them, the actuator shaft output

drive must be rotated; feed the actuator

cylinder with air at the proper pressure or

actuate the manual override, until connection

is possible.

• Assemble the insert into the EFS2000v4 as

shown in the following pictures (the engraving

realized on the insert has to correspond to

the engraving present on the EFS2000v4

bush, as highlighted in the pictures).

• Tighten the nuts of the connecting stud bolts

evenly with the torque prescribed in the

table. If no different materials are specified,

the stud bolts must be made of ASTM A 320

Grade L 7 steel, the nuts must be made of

ASTM A 194 Grade 2 or better.

• If possible, operate the actuator to check that

it moves the valve smoothly.

• If the actuators are supplied separately

from the valves, they must be placed onto

a wooden pallet so as not to damage the

coupling flange and the output shaft. In case

of long-term storage, the coupling parts

(flange, output shaft) must be coated with

protective oil or grease; if possible, blank off

the flange by a protection disk.

• In case of long-term storage, it is advisable

to store the actuators in a dry place or to

provide at least some means of weather

protection. If possible, it is also advisable

to periodically operate the actuators with

filtered, dehydrated and lubricated air; after

such operations, all the threaded connections

of the actuator and the valves of the control

panel (if present) should be carefully plugged.

Loading...

Loading...